Issues with infill and layers

Hi all,

Recently, I started to have issues with layers and infill. I appreciate your suggestions/help.

RE: Issues with infill and layers

Try dialing speed back to something like 80% or slower when this starts. I think you'll find that the gaps will close up. The default printer speed settings, especially for infill, can be a bit overly aggressive. This really shows up in large parts like yours where the printer can come up to full speed and show issues you won't see on smaller parts.

If this works, an easy fix is the adjust Filament Settings->Advanced->Print speed override->Max volumetric speed. If you're using PLA, the default is 15mm^3/s (the maximum rate of filament the E3D V6 hotend can process) which is at the upper end. I default to 11.5mm^3/s. I've recently had some PLA that required stepping back to 10mm^3/s. This setting works as a throttle on maximum speeds, so you don't have to go adjusting individual speeds on all your print setting profiles or elsewhere.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Issues with infill and layers

The other thing to check is your filament temperature - I generally print PLA at 200-205 for better bridging and overhangs but have to boost that to 210 or 215 for parts with large infills else those areas will underextrude.

RE: Issues with infill and layers

Thanks a lot for answers. I really appreciate it. 11.5mm^3 option worked quite well. I also increased the temp. 215 degrees. This PLA is little weird and and looks like requires high temperature. Both answers help me to improve quality.

RE: Issues with infill and layers

I dropped max_volumteric_speed to 10mm^3/s and increase infill_width to 0.6mm but still having issues with infill. What I realized, it looks like only in one direction of infills have problem. Do you have any suggestions for this issue? Can it be because of filament quality?

RE: Issues with infill and layers

Before trying too much else, give regular grid infill a try and see if it looks any better.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Issues with infill and layers

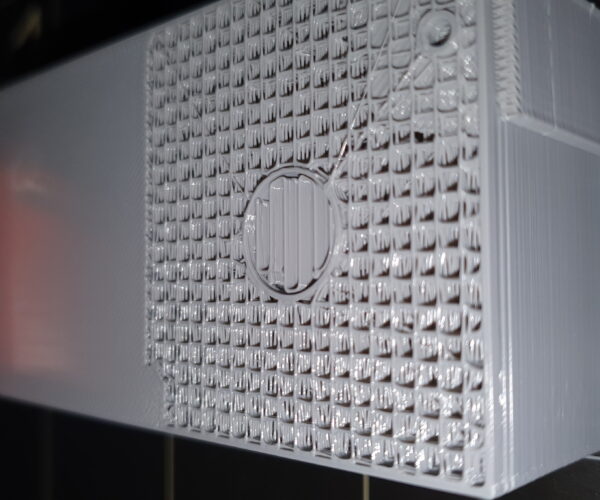

I changed material to PET-G I still have similar filling issues. I fixed on top layer issues. It appeared it is because of teflon Bowden tube in hotend. I replaced it and it solve issue of underextrusion but infill still problematic as you can see below pictures (Printed with PET-G). Do you have any idea what can cause issue?

RE: Issues with infill and layers

I changed material to PET-G I still have similar filling issues. I fixed on top layer issues. It appeared it is because of teflon Bowden tube in hotend. I replaced it and it solve issue of underextrusion but infill still problematic as you can see below pictures (Printed with PET-G). Do you have any idea what can cause issue?

RE: Issues with infill and layers

Additional info, I am using some custom settings with 0.3mm layer height. (Not very custom made from 0.35 mm settings with small adjustments) I started to think 0.3mm layer height cannot handle this cubic infill...