MMU BVOH & PLA

I've been struggling mightily with my MM upgrade. First I had purchased some eSun PVA for support structures and spent a month or so tuning parameters and adjusting hardware until deciding I'd need to reprint the filament feed to not allow as much wiggle room for the filament to bow and jam. Then I bought BVOH filament and my prints would start great but always jam within 1-6 hours. I printed this replacement part: https://www.thingiverse.com/thing:2740929 which helped with some of the jamming. But I am still getting failures by 6 hours into a print. Usually I start getting rough edges on the wipe tower, especially after it prints the seesaw pattern instead of a full layer sheet and tries to wipe on top of the gaps afterwards. I'm using Hatchbox PLA and Verbatim 55901 BVOH with 205 nozzle temperature with 60 bed temperature.

I've tried deviating from the default MMU Solubile Interface settings with the following changes:

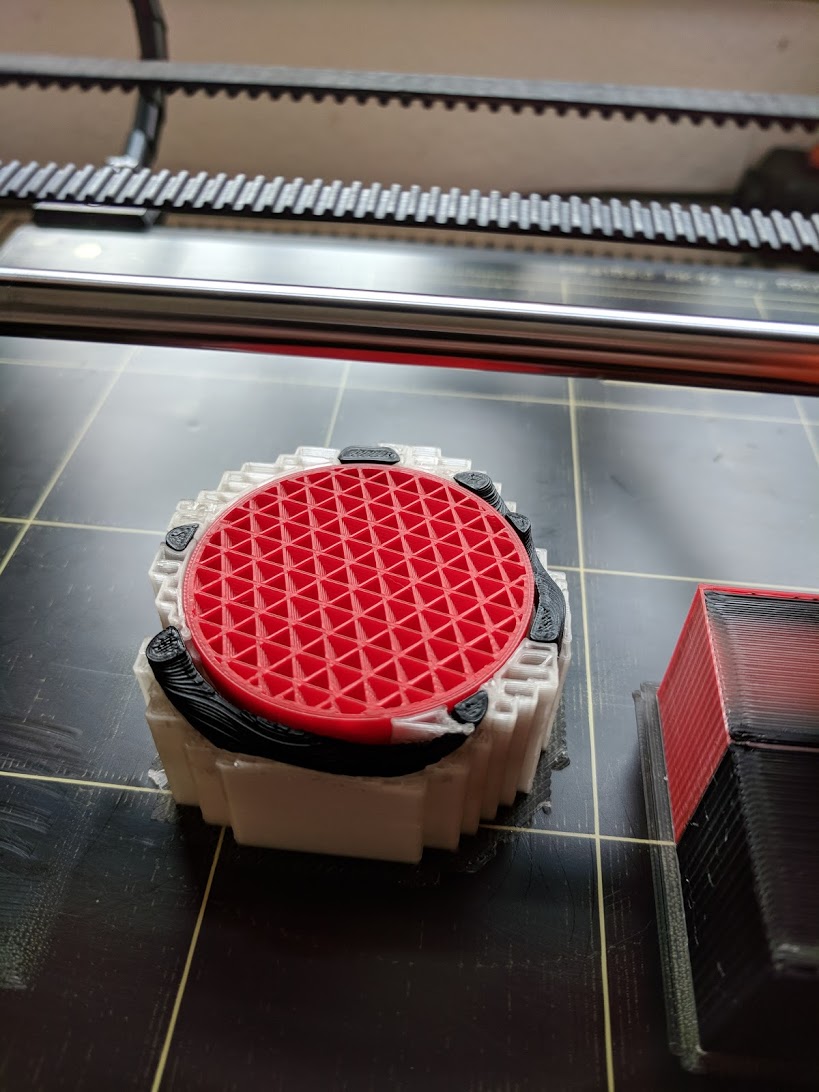

This is a good indicator, based on the wipe tower condition, early in a print that it's going to go bad. Normally it's more subtle than this but same end result:

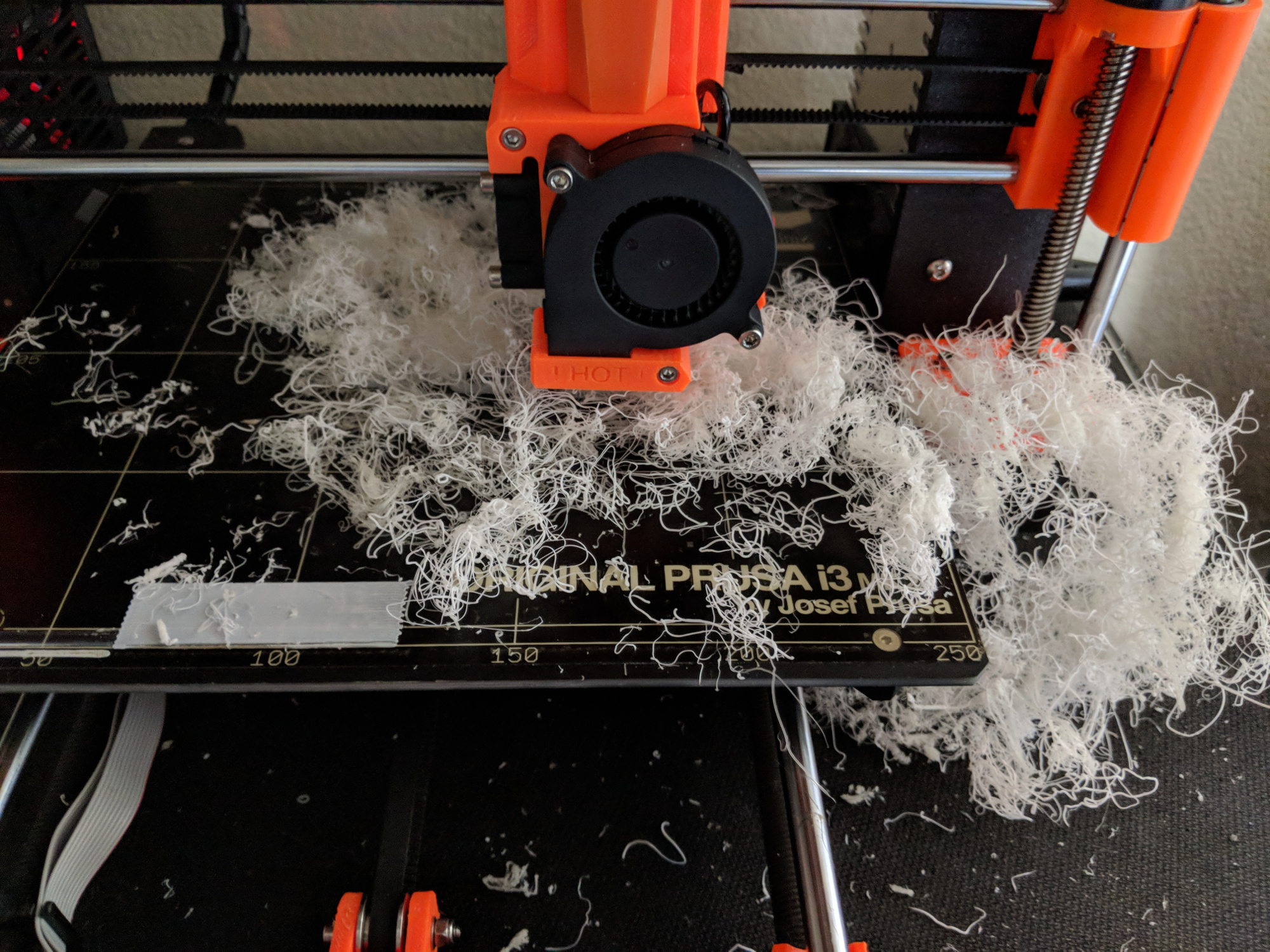

Without a sock those strands stick to the heating elements and causes a giant glob to move with the head and ruin everything (yay 2 inches of filament strands filling my enclosure). With a sock it delays the problem until the wipe tower separates some and warps upwards, causing wipes to fail and everything after that point to be jammed. When it does fail it also starts to damage the sock when rubbing against the protruded wipe tower.

Some suggestions or print configurations people have had success with would be quite helpful. I haven't got anything beyond some centimeter cubes printed to completion with 2+ materials yet. I can make other prints or try other pattern to debug but at this point I don't know what to change in combination or not to reduce jam changes.

Re: MMU BVOH & PLA

BVHO & PLA work perfectly here with default settings... BUT.... the BVOH filament must be dry, and I mean DRY.

To elaborate: I bought a pack of PVOH and printed a couple of objects without any problem. Then, after only a few days, it apparently had accumulated enough moisture so that it wouldn't stick any more. Drying the spool in the oven (3 hours at 50°C) restored it to full useability.

Re: MMU BVOH & PLA

That print looks quite nice! It's possible the filament came a little hydrated. I've had the filament in a dry box with reusable silica beads since I opened it though. I could try drying it out regardless just to be safe.

From reading some on other threads I have a theory now that maybe my enclosure is getting too hot over time (even with the enclosure door open). Each time the jams are happening one of the filaments is knobbed at the end and jams after color changes: indicating it might be staying too hot and a little molten when retracting into the tube. I've wired up a pair of computer fans to push cooler air through the back of the enclosure and will see if this helps a print overnight.

Re: MMU BVOH & PLA

Ah ha! After 6 weeks of fiddling it finally printed to completion the original miniature I had been testing.

The ambient temperature was indeed causing problems. At first I had the fans on too strong in the enclosure, causing it to not adhere and do this:

But adjusting the computer fans to 50% of maximum power, the retraction to 2mm, and lowering the nozzle temperatures by 5 degrees from the defaults, the print was able to not jam significantly enough to damage the print. You can see where it jammed a little near the top as there was some cleaning done in the room printing which I suspect pulled some of the heated air out of the open enclosure. The print recovered enough to finish but the BHOV was partially jammed when I unloaded it.

I'm going to finish getting the PID control next and record with a temperature sensor what the idea air temperature is without any extra drafts and just side fans running.