Re: Blockage troubleshooting.

I figured out the loading issue. To use a single filament / extruder you have to use the regular slic3r, not the MM version. One of the printer types is MM Single Mode. It contains the gcode for all the loading and unloading in the multiplexer. If you stop the print you have to unload promptly before it cools too much. This journey gave me a chance to explore gcode a bit. It's very simple to add your own little preferences, like having the head return somewhere at the end and raise up so you can clean the nozzle 🙂

Loading up multiple filaments and selecting without unloading seems to work perfectly since adjusting the Bowden length setting on the printer. That's probably worth checking for anyone with jamming. In case anyone reading didn't know, when you use MM Single Mode the printer prompts you to choose an extruder when you print. For our use, we'd like to load a bunch of colors and never have to load and unload since we mostly print the same TPU. One catch is the purge isn't nearly enough - the old color is still coming out when the print starts. This isn't the multicolor print scenario - it's just changing filament by selecting it manually rather than having the wipe tower.

So I guess I can exit this "blockage troubleshooting" thread but if anyone has any tips on TPU printing I'm all ears. I've run through many retraction, speed and temperature settings and I can't get near the quality I was getting from the Mk2.

Re: Blockage troubleshooting.

David

There are several issues all rolled together here, so I will try to deal with them one at a time...

First, soft filaments will require much less tension on the drive gear otherwise the pulley teeth will bite in too far and cause under feed - which you have noted - and also damage the filament which will cause feed issues later on.

Second, very soft filaments will require different loading/unloading strategy - the PLA speeds are much too high and will cause the filament to stretch on unload and compress on loading.

Third - and related to the above - is that you will probably need to calibrate the extruder for the set (minimum) tension.

Fourth - the slicer should unload filament at the end of a print; if it does not then you are using the wrong slicer profile - but I do not use Slic3r so I can't really help much with that, sorry...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Loads of potential things can cause that.

I think you need to unscrew the festo and remove the filament (don;t lose the cooling tube!)

Cut off 60cm of filament and reload (still with festo out), ensure that there is a clear path to the nozzle from MUX entry point - heat nozzle and manually feed some filament so it extrudes - remove that filament, replace cooling tube and festo.

Peter

Hi!

I tried all your suggest, and i maked a video.

All the tests works, but i still have the problem when i make a print with my MM...In the first 3/5 min about the first layer start good, but after this time (sometimes more than this minute or before) i still have the problem...

this is what happened,

During the first layer, sometimes all blocked.I used PLA and PLA ...(benchy test 2 MM)

In this other case during the first layer I had heard some "stunc, stunc" from E1 engine but not so much. After some layers this is the result. In this case i haved use PLA transparent and PVA (primaselect).

200 ° c first layer 195 ° c the others layers ..

Any other idea?

Re: Blockage troubleshooting.

Hi!

I tried all your suggest, and i maked a video.

All the tests works, but i still have the problem when i make a print with my MM...In the first 3/5 min about the first layer start good, but after this time (sometimes more than this minute or before) i still have the problem...

this is what happened,

During the first layer, sometimes all blocked.I used PLA and PLA ...(benchy test 2 MM)

In this other case during the first layer I had heard some "stunc, stunc" from E1 engine but not so much. After some layers this is the result. In this case i haved use PLA transparent and PVA (primaselect).

200 ° c first layer 195 ° c the others layers ..

Any other idea?

OK, first think I noticed is that unscrewing the MUX screw took a long time; mine is a couple of turns and the screw pulls out., Could be that your PTFE tubing is too high.

When you unloaded E1 the Z axis moved up; this should not happen at the height you had the Z axis unless the printer had been turned on with Z high.

Your filament loads smoothly to the correct position, so the Bowden tubes are not a problem.

Cooling tubes fit nicely...

Looks to feed OK with the festos attached to the MUX

Have to say that I suspect the PTFE tube may be your problem. Either not inserted properly or not formed properly.

I would like you to do a test print for me. Can you print the attached Marvin using PLA in E1 and E2.

Thanks

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Hi!

I tried all your suggest, and i maked a video.

All the tests works, but i still have the problem when i make a print with my MM...In the first 3/5 min about the first layer start good, but after this time (sometimes more than this minute or before) i still have the problem...

this is what happened,

During the first layer, sometimes all blocked.I used PLA and PLA ...(benchy test 2 MM)

In this other case during the first layer I had heard some "stunc, stunc" from E1 engine but not so much. After some layers this is the result. In this case i haved use PLA transparent and PVA (primaselect).

200 ° c first layer 195 ° c the others layers ..

Any other idea?

OK, first think I noticed is that unscrewing the MUX screw took a long time; mine is a couple of turns and the screw pulls out., Could be that your PTFE tubing is too high.

When you unloaded E1 the Z axis moved up; this should not happen at the height you had the Z axis unless the printer had been turned on with Z high.

Your filament loads smoothly to the correct position, so the Bowden tubes are not a problem.

Cooling tubes fit nicely...

Looks to feed OK with the festos attached to the MUX

Have to say that I suspect the PTFE tube may be your problem. Either not inserted properly or not formed properly.

I would like you to do a test print for me. Can you print the attached Marvin using PLA in E1 and E2.

Thanks

Peter

Ok i printed your file , and it still blocked...

I maked a video(sorry for the quality..), after some layers i listen a classic "Stunc stunc" from the E2 ...You can listen and see in this video (in first part , and after..)

Here there are some pics about the print:

Re: Blockage troubleshooting.

Yup, that's well blocked.

Unfortunately, I have an exhibition starting in the morning, so I will be away for the next few days.

I think I would suggest that you check out the PTFE tubing; ensure it has internal tapers at top and bottom and a chamfer at the bottom. Remove and re-seat the PTFE tubing; unscrew the heat break half a turn from the heat sink, insert the PTFE and lock in place while pushing down, then tighten the heat break into heat sink.

If that doesn't work then there is probably an issue with the heat break and you should talk to PR via Live Chat, linking your posts here.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Ok thank you Peter, i wrote to prusa , i hope i can resolve this issue!

Bye

Re: Blockage troubleshooting.

Hey Guys,

I hope I am writing in the correct thread. Recently upgraded my MK2 printer to MultiMaterial/S. Overall prints pretty well except for some intermittent artifacts. Right now the printer is working on the second try of the dragon model. Halfway through the first print, the printer failed to change the filament. Motors were slipping and no material was coming out of the head. I had to stop the print and disassemble the extruder. Things were clear in the PTFE tube and the multiplexer. There was a blockage inside the extruder. I preheated the extruder and manually tried to push a filament directly into the extruder. I used some force it suddenly went through.

Right now it is printing the second try. I see that the problem still exists and there are some missing layers (even across different colors), but the printer could correct itself at some point. Also, can see thick hair at a certain level of the print. Here are the photos attached.

I would appreciate help with this.

Thanks,

Ruben

P.S. I am using Hatchbox filaments.

Re: Blockage troubleshooting.

Hey Guys,

I hope I am writing in the correct thread. Recently upgraded my MK2 printer to MultiMaterial/S. Overall prints pretty well except for some intermittent artifacts. Right now the printer is working on the second try of the dragon model. Halfway through the first print, the printer failed to change the filament. Motors were slipping and no material was coming out of the head. I had to stop the print and disassemble the extruder. Things were clear in the PTFE tube and the multiplexer. There was a blockage inside the extruder. I preheated the extruder and manually tried to push a filament directly into the extruder. I used some force it suddenly went through.

Right now it is printing the second try. I see that the problem still exists and there are some missing layers (even across different colors), but the printer could correct itself at some point. Also, can see thick hair at a certain level of the print. Here are the photos attached.

I would appreciate help with this.

Thanks,

Ruben

P.S. I am using Hatchbox filaments.

Hi

Usually there are 3 or 4 possible causes of this:

Too much retraction during the print

Too high temps used

Too fast unload

PTFE not seated correctly against the heat break.

Not much point in telling us what filament you are using unless you also include recommended temps and those you are using... 🙄 Be specific and the answers will be likewise.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Hi

Usually there are 3 or 4 possible causes of this:

Too much retraction during the print

Too high temps used

Too fast unload

PTFE not seated correctly against the heat break.

Not much point in telling us what filament you are using unless you also include recommended temps and those you are using... 🙄 Be specific and the answers will be likewise.

Peter

Peter, The temperature is 210C. As far as retraction and unload speed concerned I'm not really sure. I have used the Adalinda_4MM_PLA_35H.gcode that comes with the latest software. Could you explain how do those parameters cause blockages inside the extruder?

Re: Blockage troubleshooting.

Could you explain how do those parameters cause blockages inside the extruder?

I could, but not tonight. Drop the temp as low as you can go and still have a good print. You still haven't mentioned the recommended temp range, so try 200 degrees to start with.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

I could, but not tonight. Drop the temp as low as you can go and still have a good print. You still haven't mentioned the recommended temp range, so try 200 degrees to start with.

Peter

Peter, I'm still getting blockage after reducing the temperature to 200C. How much lower can I go? What temperatures are you using to print with MM?

Is the problem caused by the hot filament getting stuck to the PTFE tube inside the heat break? Instead of a plastic tube wouldn't a metal piece be a better option?

One more thing. Just came across instructions to trim the PTFE tube: https://prusa3d.dozuki.com/Guide/How+to+trim+PTFE+tube+-+MultiMaterial/497 . When installing the upgrade I didn't see those instructions and instead used a drill bit with hand to make the hole in the multiplexer slightly deeper. Hope this should not have caused blockage issues. From what I have observed I don't get jams in the multiplexer but in the extruder itself. Also, why didnt the printer come with shorter PTFE tube in the first place?

Re: Blockage troubleshooting.

Peter, I'm still getting blockage after reducing the temperature to 200C. How much lower can I go? What temperatures are you using to print with MM?

Is the problem caused by the hot filament getting stuck to the PTFE tube inside the heat break? Instead of a plastic tube wouldn't a metal piece be a better option?

One more thing. Just came across instructions to trim the PTFE tube: https://prusa3d.dozuki.com/Guide/How+to+trim+PTFE+tube+-+MultiMaterial/497 . When installing the upgrade I didn't see those instructions and instead used a drill bit with hand to make the hole in the multiplexer slightly deeper. Hope this should not have caused blockage issues. From what I have observed I don't get jams in the multiplexer but in the extruder itself. Also, why didnt the printer come with shorter PTFE tube in the first place?

I use 200 to 205 degrees with PLA; different filaments require different temps and that's why I posted a temp tower at the start of this thread.

OK, you probably have the issue with the PTFE tubing not properly seated. It's never a good idea to "adjust" printed parts, but hopefully there will not be any damage.

I had a similar issue last evening when I tested a different heat break; my PTFE tube is very tight in the heat sink and although I thought I had pushed it down, there was a 1mm gap between bottom of PTFE and heat sink.

First, I now have a few minutes, so on to your earlier question:

Too much retraction during the print

Too high temps used

Too fast unload

PTFE not seated correctly against the heat break.

Too much retraction pulls melted filament into the cold end, where it solidifies and causes a blockage

Too high temps cause stringing on unload and those strings can block the entry of the new filament into the PTFE or heat break

Too fast unload can leave a blob of filament at the bottom of the PTFE tube - where the diameter reduces from 2.1mm to 1.9mm

PTFE not seated correctly leaves a gap between heat break and PTFE when melted filament from unloads can collect and block entry. Also the MUX will not seat properly.

In addition a badly formed lower PTFE end will cause a step in the path, again collecting filament.

So, in your situation I would re-seat the PTFE.

1. Remove MUX, front fan and fan nozzle, plus the front 2 screws in the side fan.

2. Remove the 2 screws and take off the front of the extruder housing

3. Careful with the cabling... Pull the extruder out of the housing and remove sock (if installed)

4. Heat and loosen the nozzle half a turn.

5. Unscrew heat sink with heat break and remove to workbench.

6. Unscrew the heat break from the heat sink; about 1 turn - push down the black ring around the PTFE at the top of the heat break

7. Screw in the heat break as far as it will go and back off half a turn.

8. Remove the PTFE and examine the lower end; ensure it's properly formed and measure length...

9. Insert the PTFE ensuring the chamfer is downwards; push fully home and lift the black locking ring.

10. Tighten the heat break into heat sink - that half turn backed off earlier

11. Back to printer - Screw nozzle fully into heat block and back off a quarter of a turn

12. Insert heat break and hand-tighten

13. Heat to 250 degrees and tighten nozzle with spanners

14. Cool and re-assemble

The PTFE tube should now allow the MUX to sit down properly onto the extruder housing.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Great thread PJR!

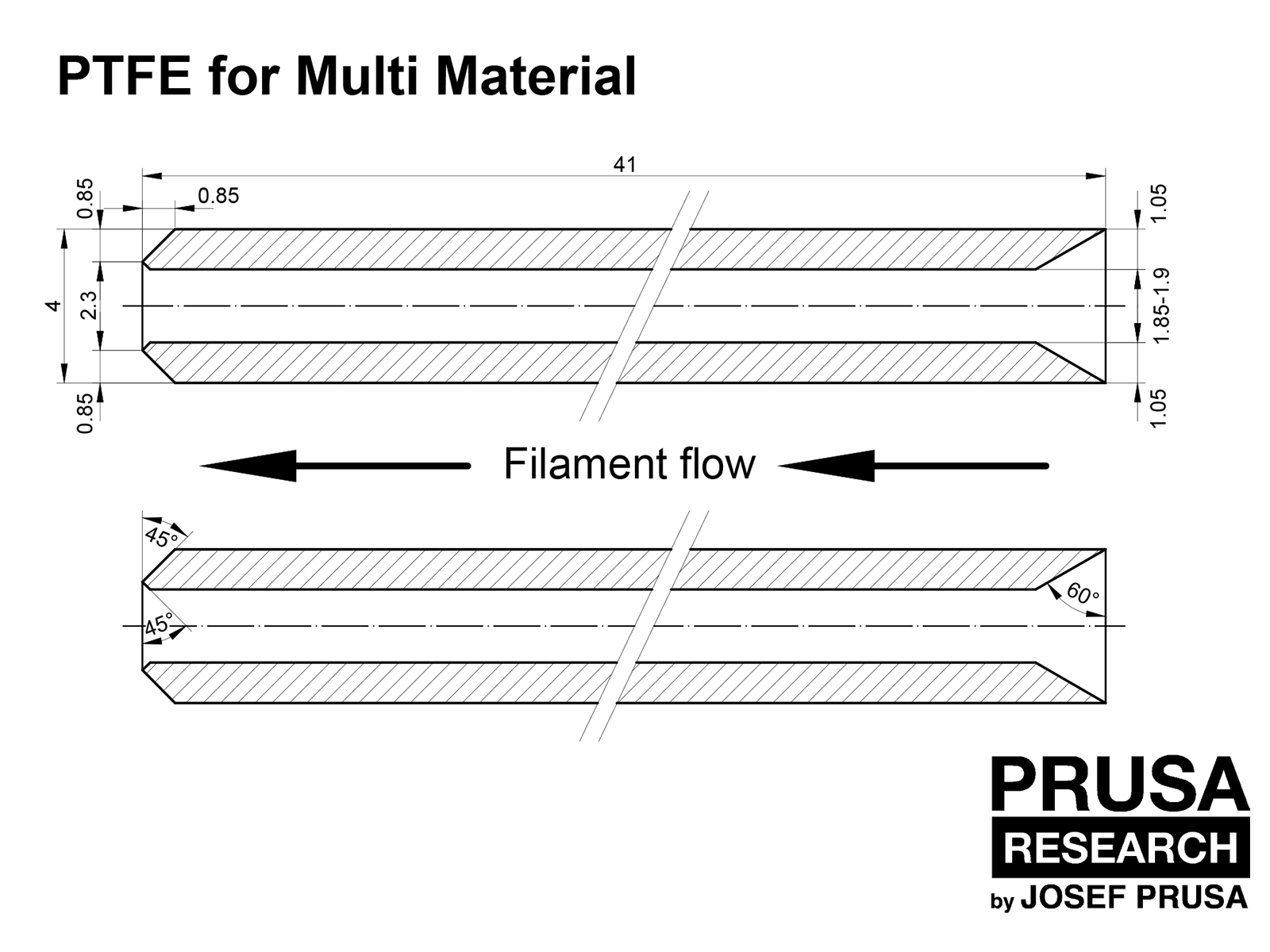

I talked to our design team and according to their sketch created a drawing of the ideal shape of PTFE tube for Multi Material.

Please keep in mind this is an ideal shape 😉

If your are making a new PTFE tube or trimming one, use this manual:

http://manual.prusa3d.com/Guide/How+to+trim+PTFE+tube+-+MultiMaterial/497

Jakub

/ Knowledge Base

The guy behind Prusa assembly manuals...

Re: Blockage troubleshooting.

Very nice and a comprehensive analysis. I have many of the same observations. It is sad sad sad to realize that Prusa keeps this going on without giving any admits that they have a huge design problem with this MM upgrade which keeps giving people troubles and which lowers the reputation that Prusa has build up. If I was the responsible company owner I stated an immediately production and sales stop on the MM option and informed my existing customers that they have discovered and issue with this, I then putted all my best engineers to solve this and informed that we are working on this. Instead Prusa follows another strategy, Making smiling videos of the next generation of printers (MK3) - making no informations and just leave all their MK2 customers with the MMU add on behind with no concessions at all. Just playing the hide game.

PRUSA THIS IS NOT OK!! I plan to find a way to get my money back for this 🙁

I can only get it to print when raising the temperature outside both the max temp of both PLA and PVA. If not using that high temp it keeps gloc up. This result in oozing and rough support structures with the PVA which again gives very bad finish in the print quality. Prusa is not giving any feedback !!! They have asked me to see if something is blocking the Y splitter????

Trust me, I'm an engineer 🙂 Always do your best. What you plant now, you will harvest later

Re: Blockage troubleshooting.

I agree with henrik j. k., PRUSA should inform its customers that there are problems with MM and they are working on a solution, if they don't manage to solve the problems, it should be a matter of course that the customers get their money back.

Martin

Re: Blockage troubleshooting.

So I've been holding off commenting here because I wanted so badly to get the MM upgrade working. Unfortunately I'm one of the ones that seems to be having a lot of problems. I've read this ( and just about all the other posts I could find ), read, re-read, read again all the manuals and still I do not have a reliable printing solution, period. The Original MK2 was rock solid and dependable, this upgrade is just a shame, between people getting non-chamfered ptfe tubes and the, in my opinion, way too tight tolerances needed to pull this all off, along with no real comment by Prusa it's like the entire upgrade was sold by a different company to make a buck.

I have to say, at this point I'm giving up, I've gotten a couple successful prints here and there but after many 10s of hours troubleshooting and trying to figure this out I just want my reliable printer back. I guess I'm not really expecting any money back or anything like that, and for the record I have ordered the MK3 as I still very much want to believe in what Prusa is doing but that's much harder to justify after this experience.

Heading off to teardown / revert my printer back to my good ol' single extruder version then hopefully back to square one and printing reliably, albeit with one filament, but reliable is reliable and I'll take that at this point.

Prusa MK 2.25 (Downgraded MMU on MK2 with MK3 printed parts)

Prusa MK3 Kit

Re: Blockage troubleshooting.

I fully agree with henrik and start to believe that Prusa is playing a really bad game with us!

I already regret to have bought this MM upgrade and have had turned my 100% reliable MK2S is some piece of junk!!! 😥

My CR-10 costs less than half but it perform actually miles better than the Prusa with MM!!!

I’m also thinking of getting my money back due to the fact that there is no useful support from Prusa!!!

Re: Blockage troubleshooting.

As all of you in this thread I have the same problem jam jam jam in the heatbreak in single mode. I have done everything I have read here - disasamble the hotend to check if the PTFE tube seats well and put back together as described with half turn of the heatbreak, tested tension screws tight and not tight, swaped back to MK2 hotend, tried different retraction parameters and I can say none of these worked for me so is there anybody who solved this blockage? I am waiting for the reply from Prusa support today and than if they cant help me I switch back to my good old reliable MK2 without MMU because with MMU I cant make a single quality print in single mode and I think that this MMU needed way more testing before it started to be sold as there is a lot of people having trouble with it and what I have read here are only complainsts and problems with this upgrade kit. 🙁