Re: Blockage troubleshooting.

Soon I'm going to take Peter's advice and search out the ptfe/ e3d issue so I can get the legendary prusa reliability back.

Travis

Did you try printing the GCode I sliced for you?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Bill

There is, of course another factor involved. With the direct drive system, retraction was less than 1mm and with acceleration it would not be possible to achieve a maximum speed of 25mm/s. With the MM upgrade and 4mm (or more) retractions higher speeds are now possible - but not necessarily wanted.

If you retract too fast you leave a blob of filament behind in the nozzle which will then ooze. Basically, retraction is used to overcome the pressure built up by the elasticity of the filament between the drive motor and nozzle; you only have to remove the molten filament from the nozzle bore (0.4mm diameter x 0.8mm long - E3D) to prevent oozing during moves.

Peter

I checked in the latest slic3r beta which i use, and the retraction settings in that are 4mm at 80mm/s

Do you have any insight why that was chosen?

And what values would you suggest? (for general use)

Re: Blockage troubleshooting.

I checked in the latest slic3r beta which i use, and the retraction settings in that are 4mm at 80mm/s

Do you have any insight why that was chosen?

And what values would you suggest? (for general use)

Well, as you have probably gathered, I do not use Slic3r. 4mm retraction would have to be used to prevent stringing with this setup when "Preload"/"Pressure Advance"/"whatever name it has today" is not in use - and currently it cannot be used in Slic3r. There is a firmware version which does implement pressure advance, and I am told it does this rather well, although I have not had chance to test it as yet.

I do, however, have a feeling that it may work very well with just a single filament type in all extruders, so I prefer to have the slicer perform this task.

With regard to the 80mm/s, it is probably calculated as being just over the maximum achievable speed at 2mm retraction distance (v^2 = 2as - ignoring initial velocity as this is zero - a = 1500, s = 2mm). 2mm because it has to accelerate and decelerate.

Some PLAs may be able to work fine retracting at that speed; others will suffer. And it is very temperature dependant.

Anyway have a look at this excellent blog regarding retraction: http://www.sublimelayers.com/search/max-results=8?q=retraction

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Some PLAs may be able to work fine retracting at that speed; others will suffer. And it is very temperature dependant.

Anyway have a look at this excellent blog regarding retraction: http://www.sublimelayers.com/search/max-results=8?q=retraction

Peter

Thanks for the link, I think I'll play around with retracts and speeds a litte.

I currently have slight stringing issues, and (more annoying) a rough surface finish when the surface has small features (i.e. not just a flat surface filles by straight lines)

It looks like the extruder leaves deposits when lifting to move to a new position.

For me the MMU is very much still a work in progress, and feels a bit unfinished, especially on the software/settings side.

Re: Blockage troubleshooting.

currently have slight stringing issues, and (more annoying) a rough surface finish when the surface has small features (i.e. not just a flat surface filles by straight lines)

It looks like the extruder leaves deposits when lifting to move to a new position.

Sounds as though the temps are a little too high. It may be that your settings are not quite right to retract for small moves; you could also try "wipe".

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Sorry for joining this conversation. I started reading this thread some days ago, but it seemed to be a other problem. After annoying days of pain and try and error, I restarted reading and found travis' description of the problem, an his pictures. And it IS the same problem.

So ... sorry for bringing in new problems 😉 but perhaps they are already solved.

I enter the same problems while printing ONE color. 4 colors are actually far, far away ... 😉

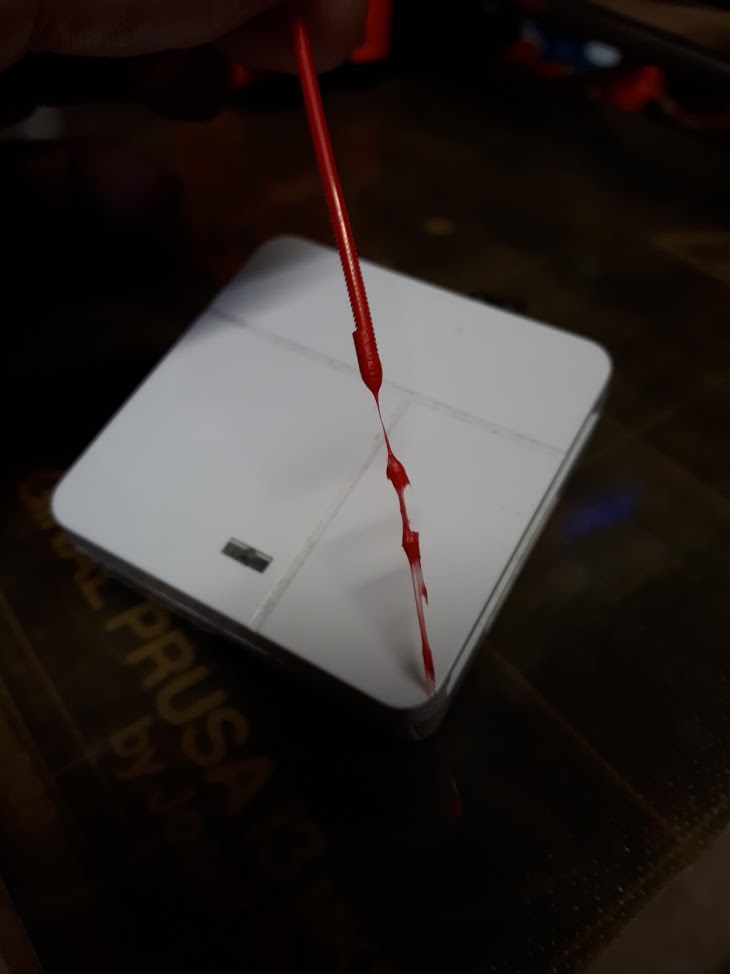

Printing starts, all fine. After about an hour the extruder motor starts skipping, even more, until everything is jammed, the result in the heatbreak looks like that.

I tried higher temperatures. No luck.

I tried less retraction, reduced from 4 to 2. Works a little better, but stucks anyway.

I tried less retraction, reduced to 0.8. Bad idea, same result, but strings added.

My next try would be to improve cooling of the extruder. A bigger fan or something.

But when I understand right, the speed of retraction is the problem? 😮

This would be an awesome easy solution.

Re: Blockage troubleshooting.

Sorry for joining this conversation.

...

But when I understand right, the speed of retraction is the problem? 😮

This would be an awesome easy solution.

Hi Daniel

Not a problem, this is the reason for the thread.

I don't think your problem is related to slicing, but it may be. I think the first thing you have to look at is the interface between PTFE tube and heat break. You need to find out if the heat break has a chamfered seating for the PTFE and if it does, the PTFE will need a ma matching bevel/chamfer.

Then you need to insert the PTFE tubing so it fits tightly against the heat break - unscrew the heat break fromt eh heat sink by half a turn, insert and lock the PTFE in place and tighten up the heat break into the heat sink.

As for retraction speeds, you could try setting 25 or 30 mm/s and a distance of 3.5mm. As this is the easiest thing to do try it first to see how it goes.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

I will try this. So only a few E3D-Extruder have this problem?

Is it a fault in production?

Re: Blockage troubleshooting.

I will try this. So only a few E3D-Extruder have this problem?

Is it a fault in production?

No, just differences in manufacture. In any event, I don't think that anyone does things as well as I do them, so I do tend to re-assemble the parts that come pre-assembled and that are a bit mission-critical... I learned that when I received my Mk2; I had a lot of blockages, so immediately checked the PTFE tubing and the lower end was not square and it was not fully inserted. Ever since, I have been rather pedantic about these things.

Thing is, I don't blame PR or the guys doing the assembly; it's certainly not a job I would want and when they are doing a few hundred every day, mistakes will happen. And it's not something that easy to QC. So I do my own QC.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Hmmm. I got it to remove the nozzle. It was very thight, even when it's warmed up.

But I wasn't able to separate heat brake and heatsink. No way. 😥

I'll reassemble it, an try a lower retractionspeed.

Re: Blockage troubleshooting.

But I wasn't able to separate heat brake and heatsink. No way. 😥

I think that sometimes, if the top of the heat break get a bit too hot, the thermal paste can harden a little.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Good evening at all .... I have upgraded to MultiMaterial my MK2S. The Single-filament prints work perfectly, but with multimaterial printing i have some trouble...one of the filaments inserted for printing is systematically blocked.

I have tried several times in these days to print 3 filaments together, ABS (prusa), PLA (prusa) and PVA (primaSelect), I use the abs for the object, pla for the supports, and pva for interface layers.

My printer is in a box , and i use this temperature:

230 °c ABS

210°C PLA

195°C PVA

After 20 prints I always have the same problem, the first layer go fine,i also changing the retraction speed to 30mm / s with 3.5mm retraction, but the abs systematically blocked when it is loaded after some layers....and sometimes also the PLA ...

I not extract my ptfe tube because it looks good,but maybe that's the problem?

Re: Blockage troubleshooting.

to print 3 filaments together, ABS (prusa), PLA (prusa) and PVA (primaSelect)

I think that may be your problem. Not sure if printing ABS/PLA is currently supported by PR.

Do you have any issues when printing multi-filament with all PLA?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

to print 3 filaments together, ABS (prusa), PLA (prusa) and PVA (primaSelect)

I think that may be your problem. Not sure if printing ABS/PLA is currently supported by PR.

Do you have any issues when printing multi-filament with all PLA?

Peter

No , i never tried to print only with PLA, i tried with ABS and PVA but I got the same result...PVA blocked... Maybe I pushed a bit too much?I only can print with PLA ?

Re: Blockage troubleshooting.

I only can print with PLA ?

No, but I believe that the filaments in use must have similar temperature requirements:

Materials with vastly different print temperatures cannot be printed at the same time. But this is theoretical as printing ABS and PLA at the same time isn’t a good idea anyways because of vastly different heatbed temperatures. Small temperature changes can be done during printing the smart tower.

Basically, there may not be sufficient time for the temperature changes.

This is something I will be looking into and already have a solution for with KISS/my post-processor by knowing the temperatures during a filament change and adjusting accordingly.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

I only can print with PLA ?

No, but I believe that the filaments in use must have similar temperature requirements:

Materials with vastly different print temperatures cannot be printed at the same time. But this is theoretical as printing ABS and PLA at the same time isn’t a good idea anyways because of vastly different heatbed temperatures. Small temperature changes can be done during printing the smart tower.

Basically, there may not be sufficient time for the temperature changes.

This is something I will be looking into and already have a solution for with KISS/my post-processor by knowing the temperatures during a filament change and adjusting accordingly.

Peter

Ok, thank you for help!

Now i'll try to print with PLA and PVA , i think is ok for the temperatures... and then I'll know if the printer prints without problem...

Maybe can i'll print PET-G , with PLA? the temperatures are similar ,both start at 195 ° C

Re: Blockage troubleshooting.

Honestly, you are jumping in at the deep end.

Start with a pre-sliced G-Code file to ensure that your printer is working as expected.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Yes you are right! 🙂

Ok i tried to print with the g-code example , and when start the print and start to extrude the engine it makes me this problem(This problem sometimes did it before and not only with the motor "E1" ):

That before I started printing, I checked the extruder, and cleaned it with this filament:

and it was ok..What could be the problem?

Re: Blockage troubleshooting.

Loads of potential things can cause that.

I think you need to unscrew the festo and remove the filament (don;t lose the cooling tube!)

Cut off 60cm of filament and reload (still with festo out), ensure that there is a clear path to the nozzle from MUX entry point - heat nozzle and manually feed some filament so it extrudes - remove that filament, replace cooling tube and festo.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Having some trouble with the MMU. We do almost all of our printing on the I3MK2 with Sainsmart TPU. We installed the MM and the filament often jams in the extruder (tried several colors just in case shore was different). We've made some progress but still can't get it going well.

We’ve played with idler tension but the extruder is not the issue. It feeds through the PTFE clean and powerful. The problem is lower down but along the way we learned something interesting while loading with the PTFE tubes removed from the MUX. While loading TPU vs. PLA that the PLA usually extends out of the PTFE tube by 22-25mm (and into the multiplexer) but the TPU barely reaches the end of the PTFE tube. The idler tension affects the length of TPU that come out - more length of filament will come out if it’s very loose (too loose to use though). As a result, I have modified the Bowden length setting on the printer to 405mm (from default 385) so that we get the same amount of material when loading TPU as we would have with PLA set at 385mm. Sorting this out has allowed us to get a print with TPU. Prior to that, there was nothing coming out until we were well past the first layer. Perhaps the feeder is flattening the flexible filament a bit which then shrinks back once its past the gears.

We're just trying single color, single extruder prints for the moment. It seems that we can get one print to complete (oozing issues aside) but if we attempt a second print the extruder will get jammed. After many prints and observations, it looks like the print completes and the filament is not pulled back from the hot end at all. Then when the next print starts, there is a rapid feed at the start which causes a jam at the extruder because the filament is already advanced from the last print. It seems like there are some gcode commands that might be missing to pull back on the existing filament at the end of the print. We're using:

Slic3R PE v 1.36.2

Firmware 3.0.12

At the end of PLA_Batman_MM-single_200um_20M.gcode the printer returns to home and does a little back and forth where it seems to dump some filament. This doesn't happen on the code that we generate in Slic3r.

When running Prusa PLA and the Prusa provided test file (Marvin_2MM_PLA_3H.gcode) we still had some issues with filament getting stuck.

When unloading, I can see that the tip of the material often has a larger diameter blob that gets hung up in the Multiplexer PTFE tube. Retraction was just 1mm and 40mm/s. We’ve tried 3 of the extruders. We removed the PTFE from the hot end and we have one tapered end (top) and a straight cut end (bottom). When pushing filament through the little piece of PTFE I can feel a resistance point inside the tube that has been created by the tube being pulled up against the lock that prevents removal (because the filament had cooled before unloading so it just pulled the whole thing and jammed).

A different issue - using the test file PLA_Batman_MM-single_200um_20M.gcode (a single color, single extruder) it seems to start off well with the first line at the front of the bed but as soon as it goes to print the skirt there is no material for the first few seconds. I don't understand this since it was just feeding ok. Maybe gcode command between those two activities is pulling the filament back too much?

We're over 20 hours of troubleshooting into this and while we've learned a lot, we're very close to just removing the MMU and putting the old one back on. If anyone has advice or experience printing with TPU on this it would be appreciated. We asked Prusa support if the material would be ok prior to installation but I'm not sure that's true. We have to get past all of these loading and feeding issues before we can even get to tackling the horrible stringy prints that the Bowden arrangement seems to be producing. It feels like there is some combination of Slic3r and firmware things that aren't working well together to coordinate the start and end of printing.