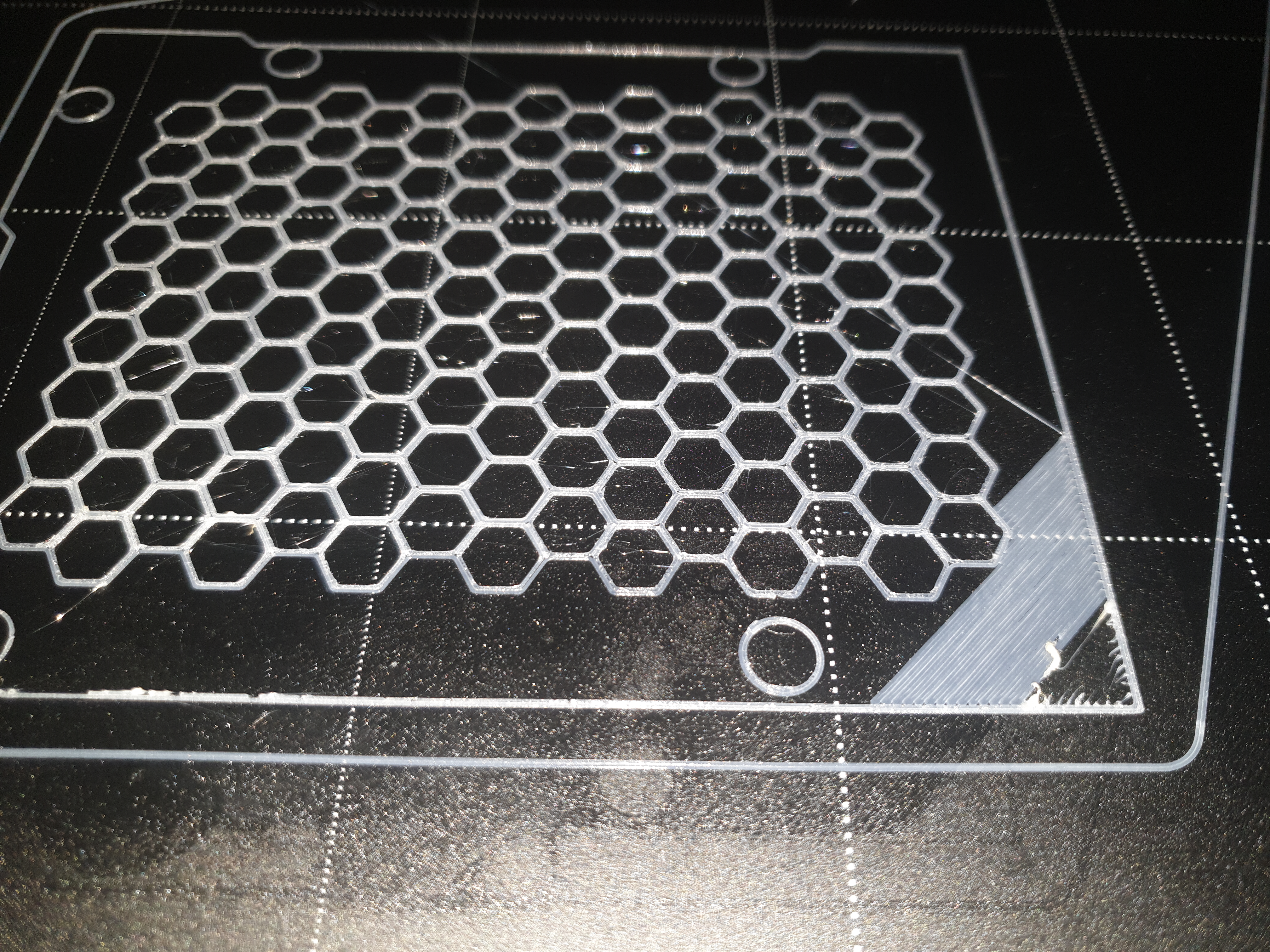

Severe nozzle pressure loss?/ underextrusion of infill after gap fill (Universal Einsy Box cover hex pattern)

Hi!

Trying to print Universal Einsy Box Cover (UEB_Cover.stl, https://www.thingiverse.com/thing:3901001/files) with PETG using default settings for prusaslicer MK3S MMU2S

RE: Severe nozzle pressure loss?/ underextrusion of infill after gap fill (Universal Einsy Box cover hex pattern)

( Argh I broke my upload screen and ended up in the wrong place somehow and can't edit or move the topic :/

RE: Severe nozzle pressure loss?/ underextrusion of infill after gap fill (Universal Einsy Box cover hex pattern)

That's not underextrusion, it's lack of adhesion.

RE: Severe nozzle pressure loss?/ underextrusion of infill after gap fill (Universal Einsy Box cover hex pattern)

Oh that's weird... I thought the lack of adhesion was just a side effect of the extrudate ripping due to uneven extrusion or something? I had to powder the plate and raise Z for testing because it's a pain to get the single layer prints off otherwise / printed POM gears without an enclosure on top of that PETG yesterday and haven't changed anything since.

So if it isn't underextrusion, is it the speed or jitter which is causing the lack of adhesion? Can't figure out why it only happen with that hex mesh pattern with gap fill enabled and can't figure out why it gets worse the longer the previous gap fill was.

RE: Severe nozzle pressure loss?/ underextrusion of infill after gap fill (Universal Einsy Box cover hex pattern)

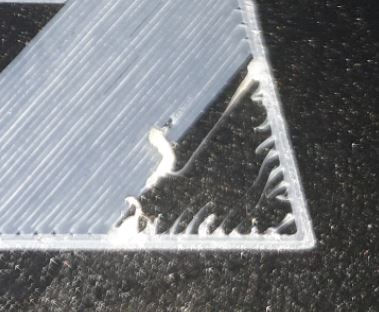

This is not gap fill:

ps: and the layer is a bit over-extruded or Live-Z is too low.

RE: Severe nozzle pressure loss?/ underextrusion of infill after gap fill (Universal Einsy Box cover hex pattern)

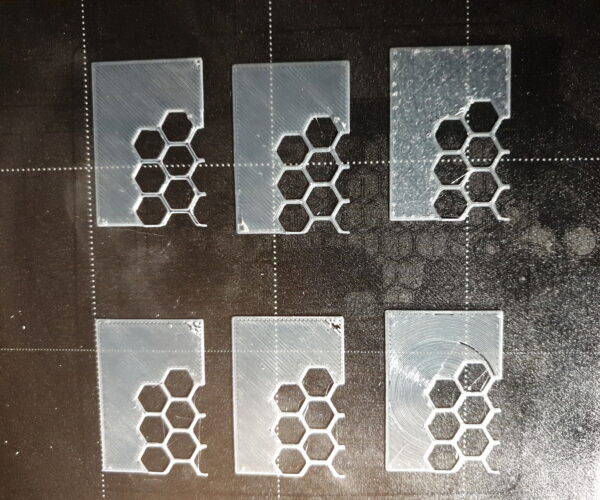

The gap fill is between the hexagon perimeters and printed directly prior to the part of the infill that fails (visible from stringing). All infill that is printed within a couple of seconds after that gap fill fails. For the second photo I disabled gap fill on one of the test parts, one is overextruded (I think I set it to 120%), the other ones have different bottom infill. All test prints I made except for the

- strongly overextruded ones

- the ones with gap fill disabled

- The ones with Hilbert curve

have a big visible gap in the infill right after gap fill.

Live-Z should be approximately 30 too high. Unless I broke something on the extruder, extrusion multiplier should be calibrated as well as possible, if it looks overextruded that *should* be either the transparency (the prints sometimes look overextruded to me because I can see the boundaries of the lines through the surface, but it's smooth to the touch) or it's over-extruded due to variance in temperature / filament / speed / don't know what. I can't tell from the photos which one it is.

Looking at the cutout with the archimedean chord infill again, I just noticed there's a fat string going from the end of the gap fill to BETWEEN the missing part of the infill and the (late) beginning of the infill. This should only be possible, if the beginning of the infill was stuck to / dragged away by or together with the string, right? Or a blob accumulated on the nozzle during gap fill? Why only after gap fill?? So, the problem could be: "fat string after gapfill" which means, it's probably overextruded after all and slightly too hot, it just doesn't accumulate as much during normal infills? Or are there any other possible reasons why that happens after EVERY gap fill specifically? The rest of the time, those strings don't seem to bother the print.

Going to measure extrusion multiplier again, maybe the filament has fluctuations. Also temperature, maybe I broke the thermistor again. Anything else I should try?

RE: Severe nozzle pressure loss?/ underextrusion of infill after gap fill (Universal Einsy Box cover hex pattern)

Definitely too low. Raise it a little and clean that sheet. As little as +0.020 could make a difference.

--------------------

Chuck H

3D Printer Review Blog

RE: Severe nozzle pressure loss?/ underextrusion of infill after gap fill (Universal Einsy Box cover hex pattern)

@idontwantapublicusername

The best approach is to save a project that reliably demonstrates the problem you are having. Rename the file adding .zip the filename and post it here (example.3mf.zip).

RE: Severe nozzle pressure loss?/ underextrusion of infill after gap fill (Universal Einsy Box cover hex pattern)

I think you are printing an einsey box for the printer. This is one of the most challenging prints because you must have Z absolutely perfect. I did a full place first layer test before attacking this one.

I used this:

https://www.prusaprinters.org/prints/48437-ultimate-first-layer-calibration-patterns

--------------------

Chuck H

3D Printer Review Blog

RE: Severe nozzle pressure loss?/ underextrusion of infill after gap fill (Universal Einsy Box cover hex pattern)

I think you are printing an einsey box for the printer. This is one of the most challenging prints because you must have Z absolutely perfect. I did a full place first layer test before attacking this one.

I used this:

https://www.prusaprinters.org/prints/48437-ultimate-first-layer-calibration-patterns

I mistyped. I think you are printing the same one I printed.

--------------------

Chuck H

3D Printer Review Blog

RE: Severe nozzle pressure loss?/ underextrusion of infill after gap fill (Universal Einsy Box cover hex pattern)

Z variance wasn't a problem, I just posted in the wrong category / the "SuperPINDA" makes levelling super easy.

I think I found the problem: the bondtech gears were encased in a thin waxy layer. During gap fill, the filament probably retracts, then slips during ramming (/deretraction?) - so it ends up further retracted than it should be and the more gap fill there is, the further the filament is retracted?

Well, so far for the current theory, not sure if it makes sense. Can't reproduce the problem any more after I swapped the gears for some new ones, going to try a couple of prints to test if it happens again. Tried to clean the old gears with acetone and dichlormethane but they still feel weird (kind of like a cracked candle) and don't have that tiny "bite" that they're supposed to have.

RE: Severe nozzle pressure loss?/ underextrusion of infill after gap fill (Universal Einsy Box cover hex pattern)

@idontwantapublicusername

Then the problem solves in my book.

--------------------

Chuck H

3D Printer Review Blog

RE: Severe nozzle pressure loss?/ underextrusion of infill after gap fill (Universal Einsy Box cover hex pattern)

Yes, results have been consistent so far. Also cleaned the inside of the nozzle since I don't know what the extruder has been chewing on (Filament? PTFE Tube? Or maybe I accidentally used hair spray instead of air spray... possibly all of the above).