Scarring of Top Surface on MK2

All,

I'm having an odd problem that hasn't cropped up, before. The top surfaces of my prints appear to be damaged by heat, but I can't see evidence of the hot end touching the filament.

Does anyone have any ideas, based on the picture? I've run hundreds of rolls of mostly PLA through the printer, and have never had this problem. I'm using Slic3r-1.41.2 on Linux. I've tried both my standard eSun filament and Prusament, with similar results.

Thanks!

- Alex

Re: Scarring of Top Surface on MK2

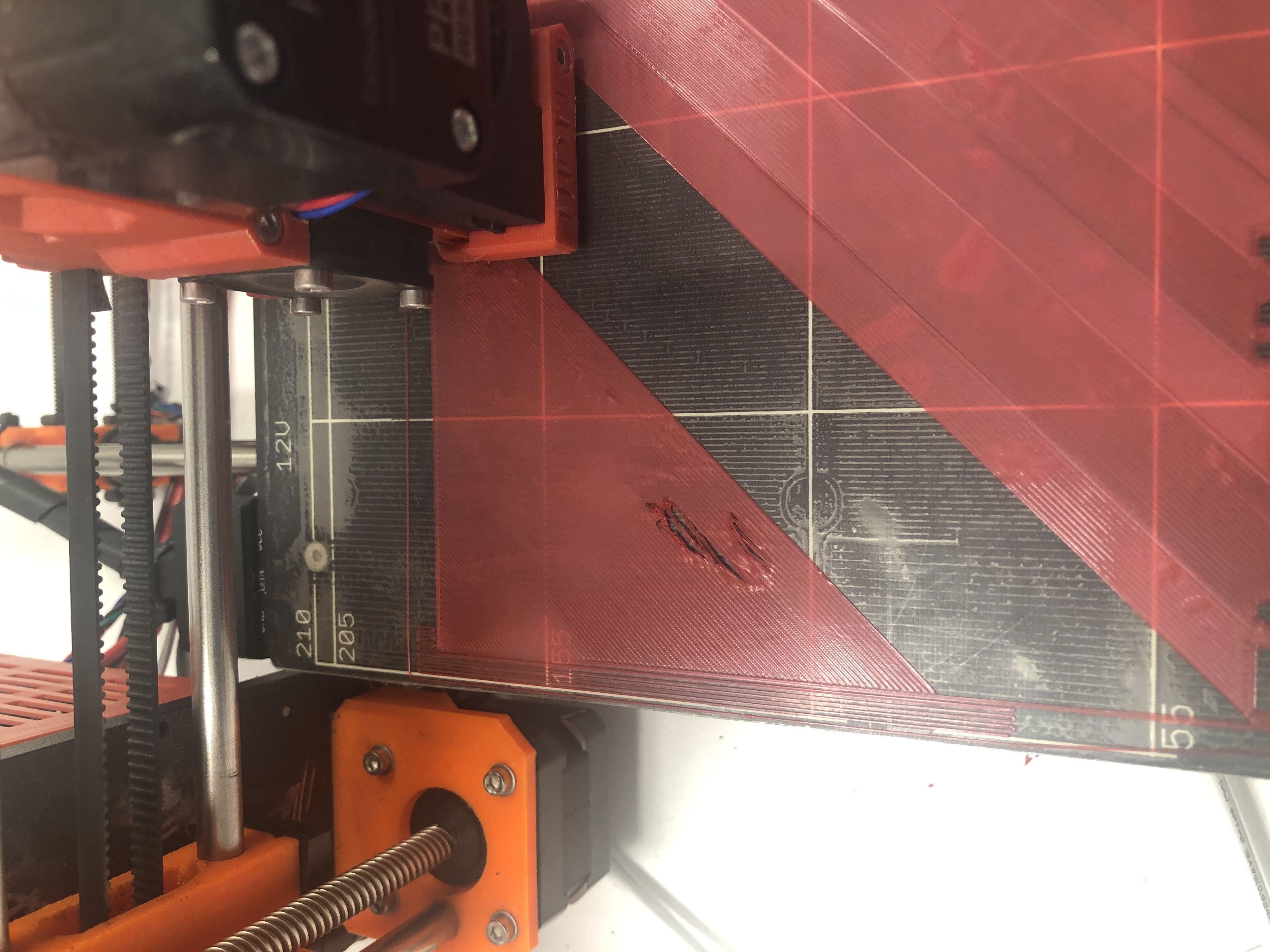

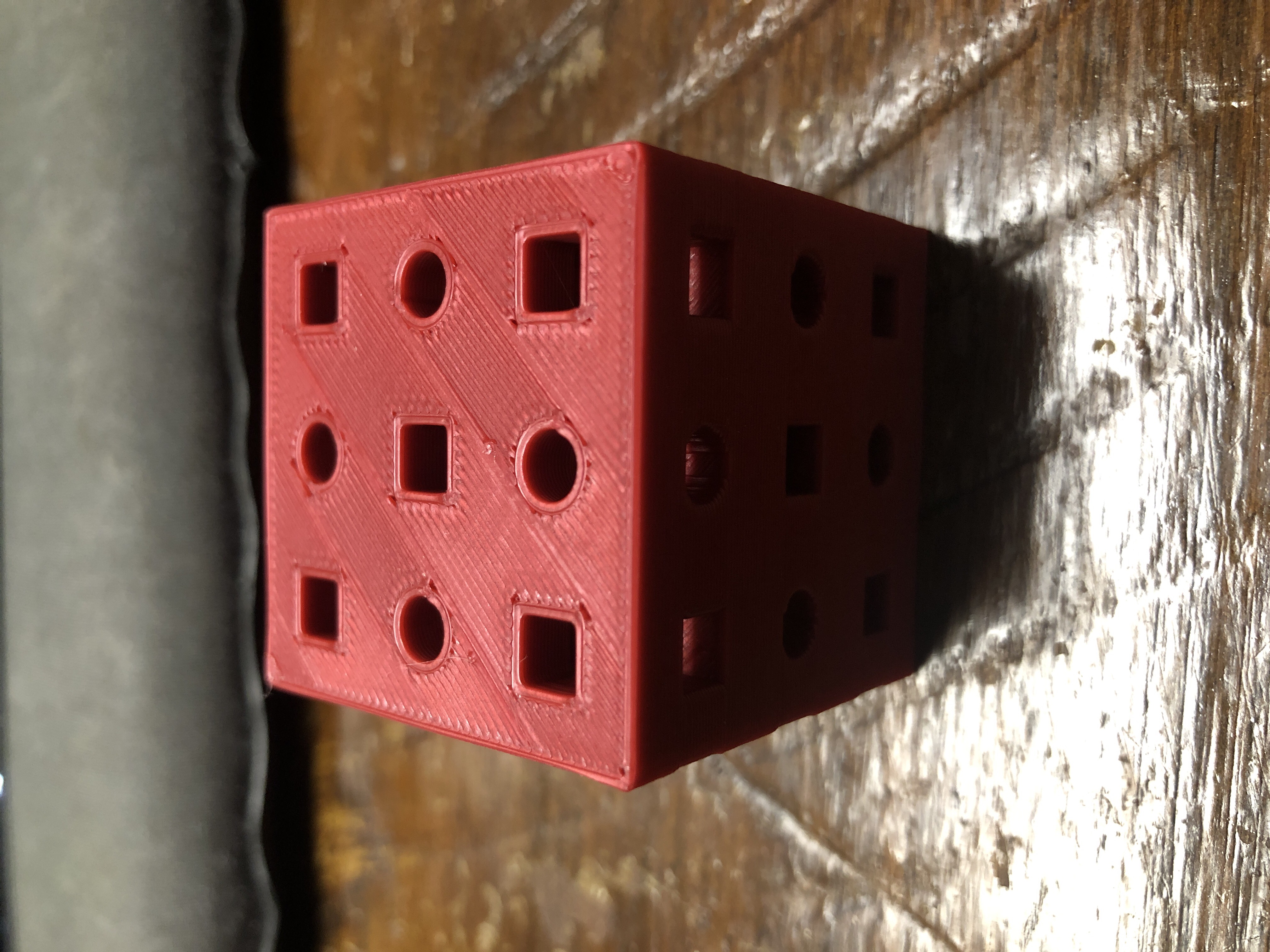

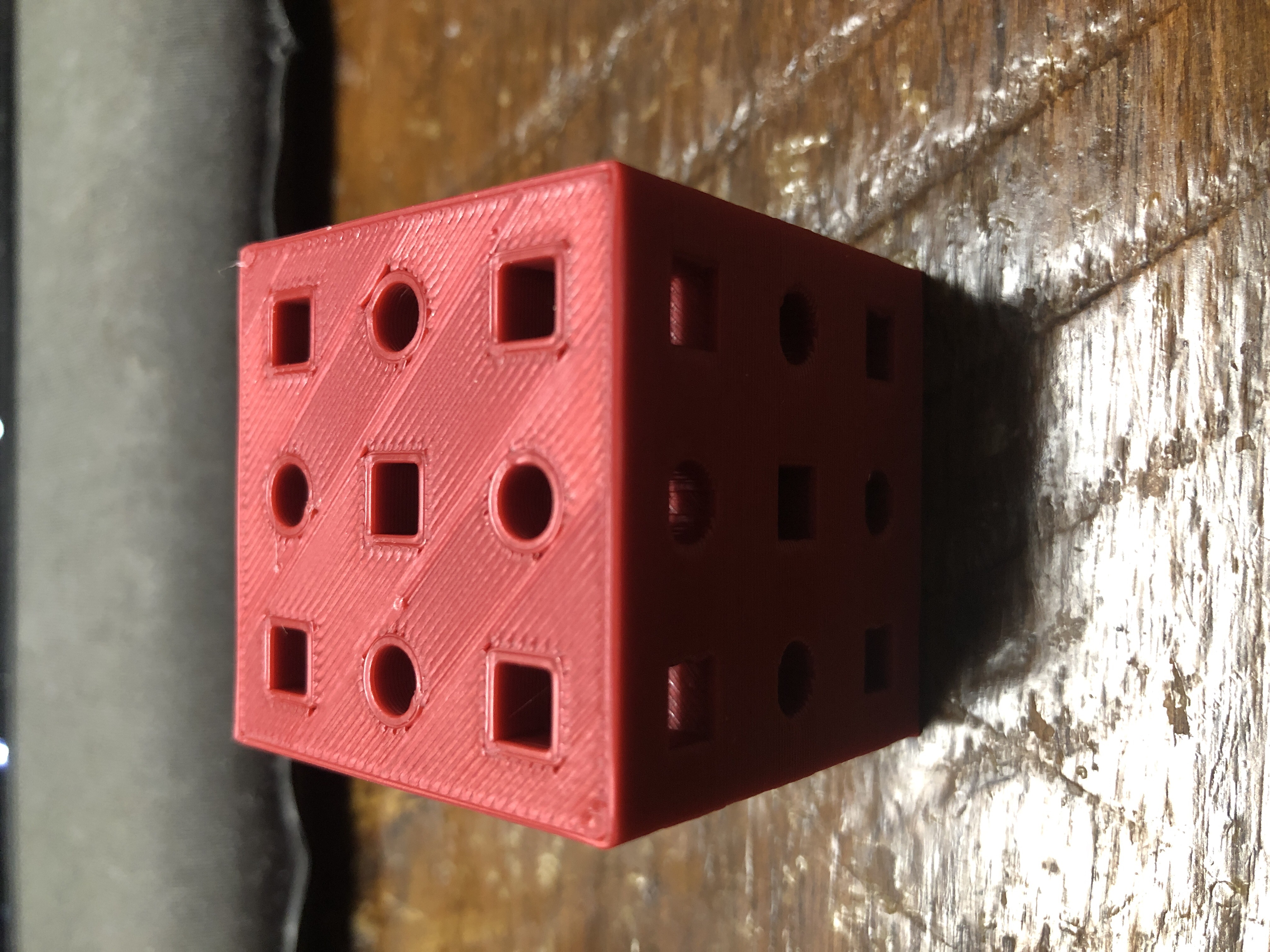

I'm still having the problem that I mentioned in the previous post, but now I'm even more frustrated. I'm currently using Pearl Red PLA filament (sold, but not made, by Prusa) that I bought in May 2018, and getting issues like this:

Previous to starting this print, I had put the spool in my filament dryer, overnight. I also cleaned and re-calibrated my printer, to no avail.

Any suggestions would be most welcome.

- Alex

Re: Scarring of Top Surface on MK2

If it happens on the first layer, then you need to clean the bed and maybe roughen the surface a little bit in the spots where it doesn't stick.

Overall the print doesn't look good. I would try with different filament first before searching for hardware issues.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Scarring of Top Surface on MK2

Nikolai,

Thanks for replying!

What would you use to rough up the surface of the PEI? I've cleaned the PEI with isopropyl numerous times, and that hasn't seemed to make much difference. I had initially assumed that oil build-up on the PEI was the issue, but after much cleaning, I had given up on that idea.

- Alex

Re: Scarring of Top Surface on MK2

I usually use acetone tissue rubbing on ABS part (failed or not needed part anymore) and then applying it to the sheet. This way I'm getting a tiny ABS film which solves any adhesion issues for PLA.

You could also use very fine sandpaper or what also worked for me is to apply blue tape on the spatula and rub it over this space.

This two methods worked best for me. But there are numerous other options to improve the bed adhesion. You need to find for yourself what is practical for you.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Scarring of Top Surface on MK2

Nikolai,

I'll give that a shot.

However, I do also want to note that when I say "surface scars", I don't just mean on the first layer. These issues can crop up on any layer, for example, this one, which appeared at Z=3, on a 0.35mm layer height print:

Do you have any thoughts on that? I do see some underextrusion on the print, as well, but it's pretty minor.

The one common factor might be that the surface scars seem to happen when the printer is running slowly, like when it is printing the first layer, or top solid infill.

Thanks!

- Alex

Re: Scarring of Top Surface on MK2

Under extrusion looks major to me. Again, I assume you have a bad filament roll but it's hard to tell and easy to try.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Scarring of Top Surface on MK2

OK, I can definitely give a shot at bumping up my extrusion multiplier, and printing some large 1-layer sheets. I'll do that as soon as the current (long) print is complete. I'm using default MK2/S settings on -current Slic3r PE.

However, the problem occurs with multiple different rolls of filament, from several vendors (at least eSun PLA+ and Prusa-supplied PLA are confirmed).

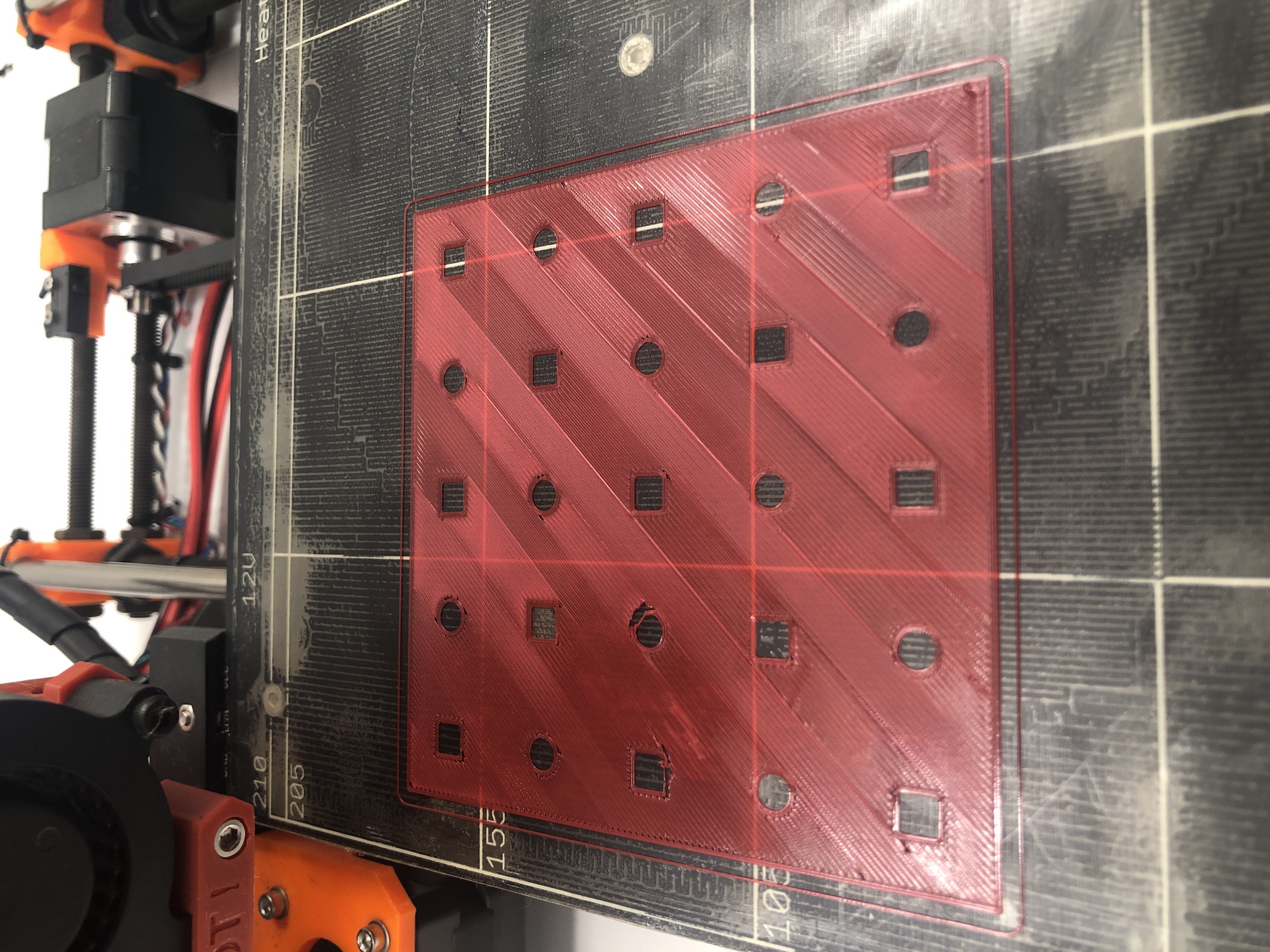

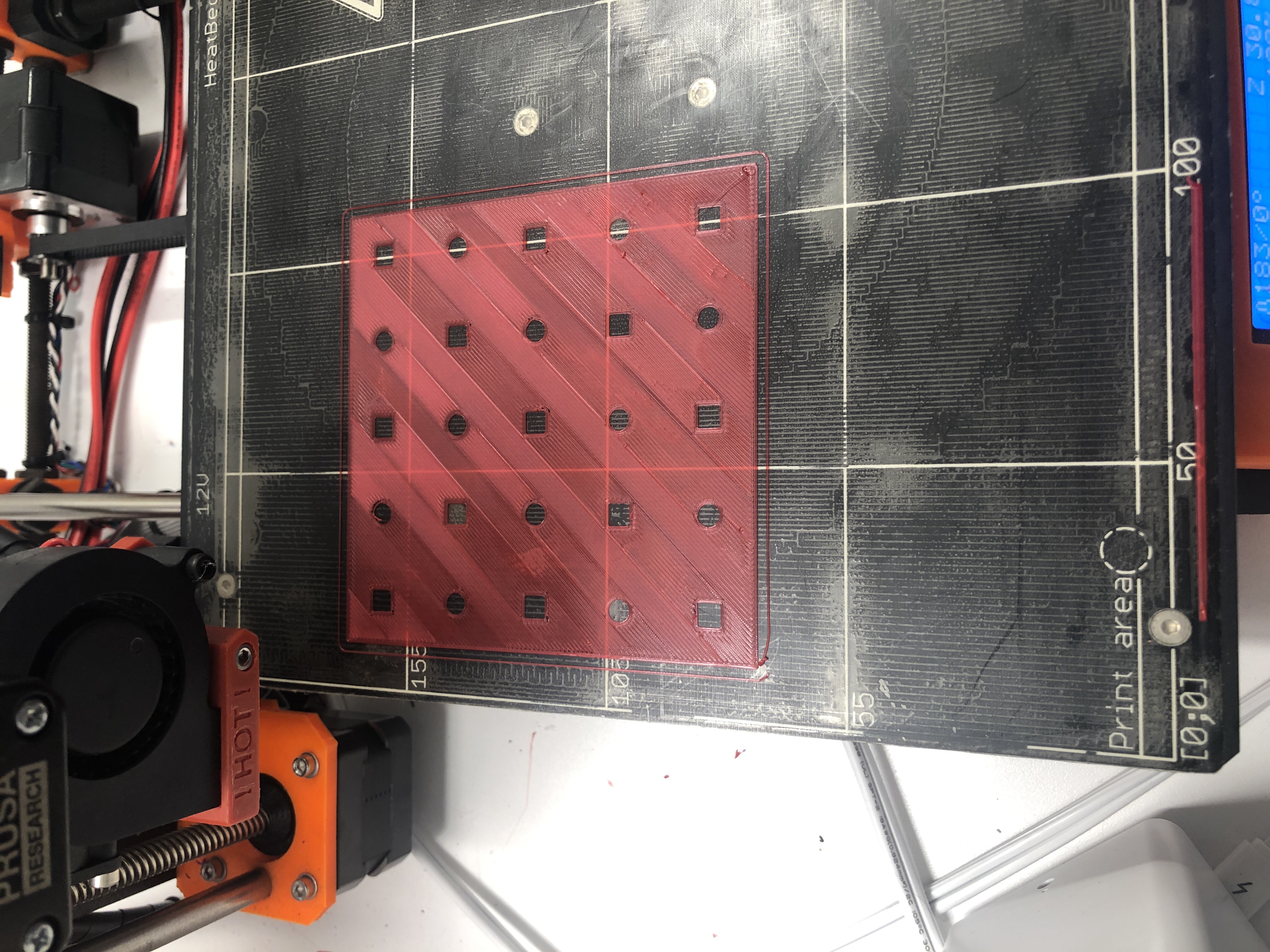

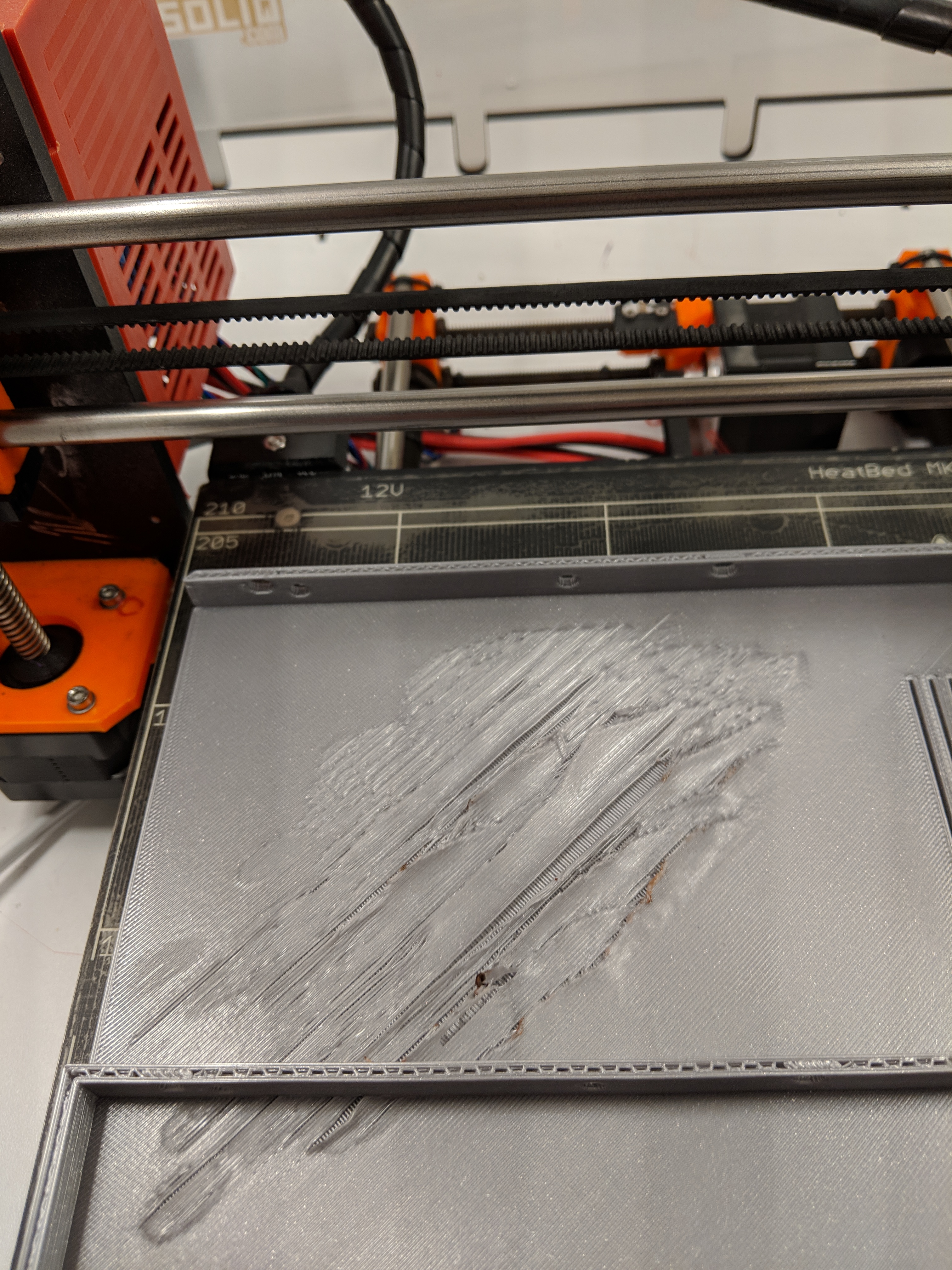

[UPDATE] Here are the results, in a bad spot on the bed, before cleaning (again):

And here are the results, in the same spot on the bed, after cleaning with acetone and then with isopropyl 70%:

And here are the results at 102% extrusion:

Thanks!

- Alex

Re: Scarring of Top Surface on MK2

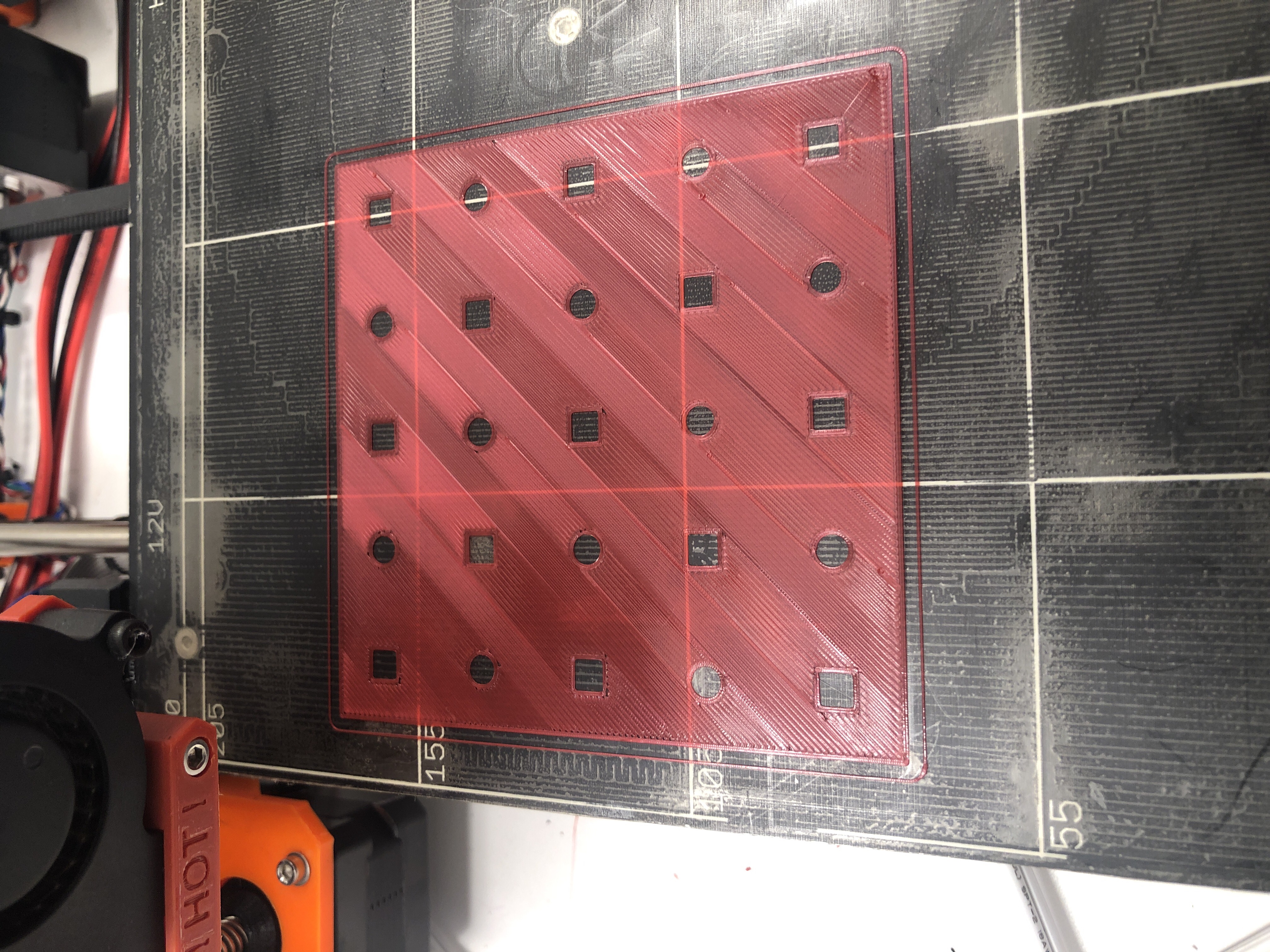

Here is a 40mm^3 calibration cube, printed with 5% overextrusion:

And from a different angle:

Somewhat better, but still a bit of underextrusion on the top layer. I'm wondering if this filament isn't a bit below the standard of 1.75mm.

- Alex

Re: Scarring of Top Surface on MK2

Darn it...I thought that maybe changing filament after the deep clean would fix things, but definitely not!

This is what I just woke up to see, using a brand new roll of Prusament, fresh from the box:

At this point, I have no idea what to do. There is no underextrusion, so that's not the problem. Something is causing layers where the hot end slows down to bubble up, and then when the hot end hits a raised bubble, it tears it open. I'm lucky (I guess) that this 10-hour print didn't fail entirely, though I am quite unsure that the result will be usable.

- Alex

Re: Scarring of Top Surface on MK2

That indeed is a very big print.

I experienced something similar myself and could guess, that this is bad layer bonding (as well as bed adhesion)

for to low print tempearature and/or to much cooling.

The bad bonding is clearly visible at least.

For that print I would my PLA have at some 220°C the bed at 65° for the 1st three layers and then at 55°.

Fan speed at max. 60% and blipped to 100% below 12sec layer time.

Re: Scarring of Top Surface on MK2

Ok, if it's not the filament and I assume you're still using same slicer settings/gcode which is known to work. Then it must be hardware related.

At this point you need to make it reproducible and watch the hardware. Because it can be anything it's hard to give you a good advise.

Because of the layer bonding I would concentrate first on all elements which are responsible for extrusion.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Scarring of Top Surface on MK2

That's an interesting idea, Alexander.

The print that I showed is printing at the default temps for Prusament, 215C on the hot end and 60C on the heated bed for all layers. Also, my printer is in an enclosure, though running with the door open for PLA. So, the ambient temperature would be somewhat higher than room temperature, which is usually around 16-18C.

I'll give it a shot. You have given me the idea that possibly falling room temperature could have something to do with the issue, since the heat in my office turns off after midnight, and the room drops to 16C.

- Alex