Help getting rid of Z-banding / visible horizontal layers

I've had my i3 MK2 since the end of December, and solved most little issues now except the Z-banding.

I have:

upgraded to a ball bearing spool holder to ensure it doesn't jerk pull on the spool

tried different filaments from different manufacturers, like Hatchbox, ICE Filaments and Das Filament

upgraded to 200 euro IGUS precision shafts + Drylin bearings -> a bit less horizontal layers, still visible

i used MOS2 oil and PTFE oil on the shafts to ensure that it just glides now, currently i'm staying with PTFE oil

calibrated to 100mm extrusion for correct E-Steps -> still visible

checked Z-shafts on the Z-motors, they are not bent

tightened all belts via the help of a phone guitar app to ensure the correct belt tightness (passes built in belt check in 3.0.10) -> still visible horizontal layers

upgraded to a freakin' E3D Titan Extruder and calibrated it again to 100mm -> still visible, but now slightly worse than Prusa's stock X-carrige

calibrated the extrusion multiplier via reprap guides to 2 shells (not just one outer shell) to a correct 0.98 -> still visible horizontal layers

set extrusion multiplier to 0.9 -> a bit less horizontal layers

set extrusion multiplier to 0.8 -> almost no horizontal layers visible anymore, but gaps in the top infill and 3D prints are a bit more brittle

It's mostly visible when the light hits the print from the right angle, and very visible with brighter colors, like white

I don't know what to do anymore.

Anybody got a way to solve this?

Re: Help getting rid of Z-banding / visible horizontal layers

Looks similar to what my prints exhibit, at least to my inexperienced eye. No solution, yet.

Re: Help getting rid of Z-banding / visible horizontal layers

Dude i am dealing with the same thing. Thats nuts. i have taken apart the whole Z assembly and put it back together again thinking i was getting ZWobble from...something... I took the Spool of the top of the printer since that can cause the Z axis to wobble a bit. I Made sure everything was SUPER tight and square. im at a loss. I have the dragon printing right now.... i printed + finished a Dragon about 20 minutes before i did all these "adjustments" so i will have a pefect side by side comparison as soon as i get home from work with the previous dragon and this new dragon. hopefully i solved it.

Re: Help getting rid of Z-banding / visible horizontal layers

Try to turn off Lift-Z option in Slic3r.

Re: Help getting rid of Z-banding / visible horizontal layers

Try to turn off Lift-Z option in Slic3r.

I tried that :/ unfortunately there was no difference in quality. Thank you for the suggestion though! Hell any input at this point is welcome

I tuned my steps/mm to be insanely accurate. after 3 runs, the extrusion distance was always within 0.5mm of the 100mm distance. The artifacts were hidden a little better. but its obvious there is something going on mechanically. Only problem is, i am completely stumped as to what it may be.

One guy recommend to put your z axis as high as it can go, then loosen your Acme Nylon black screw guide things ( cant think of the name) .. So you loosen those up and allow them to set naturally, then tighten them back down ( not too tight though). When this is done, make the Z axis go alll the way back down in one fluid movement and look at your Z screws from above to see if they slowly deviate to 1 side or the other. If they do, then repeat the process until they stay in place when moving the z axis up and down. Give that shot, see if that helps your issue. All it did for me was atleast reassure me my Zaxis is perfectly straight.

it's a little sad when my Anet A6 is producing better looking prints than my MK2S -.- . it hurts right in my melon heart.

Re: Help getting rid of Z-banding / visible horizontal layers

Do your layers look more like A or B? (see image)

In case of A it is most likely issue of X/Y axis (check belts, pulleys, bearings etc), but in case of B it is most likely caused by Z axis (uneven layer height for example).

Does the problem look different when you change printing speed?

Did you calibrate extruder?

Did you try to change number of perimeters, infill type and density?

Re: Help getting rid of Z-banding / visible horizontal layers

Do your layers look more like A or B? (see image)

In case of A it is most likely issue of X/Y axis (check belts, pulleys, bearings etc), but in case of B it is most likely caused by Z axis (uneven layer height for example).

Does the problem look different when you change printing speed?

Did you calibrate extruder?

Did you try to change number of perimeters, infill type and density?

mine looks like B. Do you know whats up?

Yes i calibrated my extruder to within 0.2mm of the 100mm extrusion technique. I ran the same test 3 times and was well within margin of error.

and yes i have changed the number of perimeters. it seems to pop up when there is more than 1 perimeter. the lions mayne cylinder for example. shows horrible results when printing with more than 1. but with only 1, it looks pretty good.

benchy exhibits the same issues. the lines just dont match up for some reason.

Yes, the problem pops up at half the defaults speeds.

Re: Help getting rid of Z-banding / visible horizontal layers

Maybe your live Z is too low? Eventually making perimeters squish each other.. Just my thinking..

Re: Help getting rid of Z-banding / visible horizontal layers

Saw someone somewhere :-), that changed the perimeter to be printed outside-in instead of inside-out. On the pictures he showed the banding was improved.

Haven't tested this myself though.

---

Gert

Re: Help getting rid of Z-banding / visible horizontal layers

What about example gcode files provided by PR? Do they suffer the same problem?

Re: Help getting rid of Z-banding / visible horizontal layers

What about example gcode files provided by PR? Do they suffer the same problem?

Yes sir they do unfortunately

Re: Help getting rid of Z-banding / visible horizontal layers

Well, looks like I'm out of ideas, sorry. But definitely there is some mechanical problem.

Re: Help getting rid of Z-banding / visible horizontal layers

Have you tried PJR's 9 square calibration process ? On this thread.. http://shop.prusa3d.com/forum/prusa-i3-kit-building-calibrating-first-print-main-f6/hyperfine-bed-leveling--t4330.html

Prusa i3 MK2s MK2.5s Mk3 Mk3s BearPrusa Zaribo 320 - Kit Build - Rc Driver - Tweak freak...

“I know nothing about surpassing others. I only know how to outdo myself.†-Bushido-

Re: Help getting rid of Z-banding / visible horizontal layers

Hello!

I have the same problem with my MK2S...

Have you found a solution?

Re: Help getting rid of Z-banding / visible horizontal layers

You might want to check for loose connections in the bundle that comes out the back of the extruder.

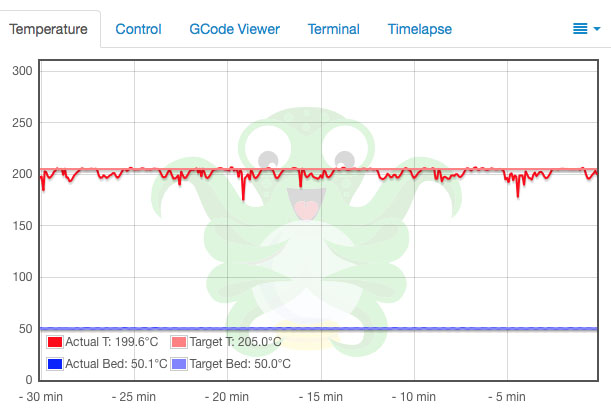

If the temperature is varying greatly due to an intermittent connection, you will get this type of banding, see temp plot below. Similar banding on this print.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Help getting rid of Z-banding / visible horizontal layers

Got my mk2s just a few weeks ago and went through the usual calibration of Live Z, extruder, PID, bed PID.

Printed a couple of the tree frogs and they came out very nice. A bit of cob webs at the lowest levels, but cleans up easily. Thing is the filament would bind a bit in the factory holder so I was baby sitting these prints and manually feeding the filament.

I then moved my filament spool from the top to behind the printer on a Lego built spool holder and used a piece of copper wire as a top guide.

Printed my third frog, and it has these occasional ripples. Seemed to me that the filament feed was occasionally getting a bit snug and the pull on the spool was affecting the Z height (best guess). I was still having to manually assist the spool unloading. I also found there was a 'knot' in the filament on the spool. Untangled that for the next prints and am more careful to ensure that doesn't happen again.

I then printed a couple of parametric spool holders with a single 608 bearing in each and put the spool back on top.

Now making a print of buddy and I am not touching the spool at all (letting it feed naturally), and it looks to be printing with high quality again.

I'm still wanting to move the spool off the top and to behind the printer (or maybe to the top of an enclosure).

I suspect you may be getting the filament coming off the spool in tight and loose sections. I've read in other forums that it isn't a bad idea to completely unwind the spool onto another spool to ensure there is no tight spots in the spool.

EDIT - Printed two Buddies and one tree frog, and all is nice and smooth again.

Re: Help getting rid of Z-banding / visible horizontal layers

**UPDATE**

I am STILL having the same issues with my MK2S. 🙁 i am pretty disappointed with my purchase and just overall frustrated. I've tried many many different "fixes" from structural to slicer settings to different spool holder designs, firmware updates, etc, etc, etc, etc...

I can hide some of it if i under extrude a bit but the problem is still obviously there. I am at a loss.. -.-

the Prusa team (Honza) was very helpful. But even they could not solve it. i haven't contacted them in a while... Maybe i should try working with them again.

IF anyone has come up with a solution, please let me know.

Re: Help getting rid of Z-banding / visible horizontal layers

Is it perhaps this? https://www.simplify3d.com/support/print-quality-troubleshooting/#vibrations-and-ringing

I just bought a stone (40x40cm) for my printer, that helped a lot reducing vibration, noise level went way down too. Also I have my printer in silent mode, perhaps that makes a difference.

What I also did, is calibrate the extruder, does it really extrude 10cm of filament. Perhaps its under extruding sometimes? Perhaps its the selected print temperature? Sorry if you have tried any of these things, I didnt read the whole thread.

Re: Help getting rid of Z-banding / visible horizontal layers

NO sir. sorry the benchy showed up really strange here on the forum for some reason. it doesnt have lines that swoop up like that, its all straight parallel with the layers. the layers shifts slightly every 1.5mm then go back to the proper position =. then shift..then go back..then shift.. bleh.. -.-

Re: Help getting rid of Z-banding / visible horizontal layers

I've had my i3 MK2 since the end of December, and solved most little issues now except the Z-banding.

I have:

upgraded to a ball bearing spool holder to ensure it doesn't jerk pull on the spool

tried different filaments from different manufacturers, like Hatchbox, ICE Filaments and Das Filament

upgraded to 200 euro IGUS precision shafts + Drylin bearings -> a bit less horizontal layers, still visible

i used MOS2 oil and PTFE oil on the shafts to ensure that it just glides now, currently i'm staying with PTFE oil

calibrated to 100mm extrusion for correct E-Steps -> still visible

checked Z-shafts on the Z-motors, they are not bent

tightened all belts via the help of a phone guitar app to ensure the correct belt tightness (passes built in belt check in 3.0.10) -> still visible horizontal layers

upgraded to a freakin' E3D Titan Extruder and calibrated it again to 100mm -> still visible, but now slightly worse than Prusa's stock X-carrige

calibrated the extrusion multiplier via reprap guides to 2 shells (not just one outer shell) to a correct 0.98 -> still visible horizontal layers

set extrusion multiplier to 0.9 -> a bit less horizontal layers

set extrusion multiplier to 0.8 -> almost no horizontal layers visible anymore, but gaps in the top infill and 3D prints are a bit more brittle

It's mostly visible when the light hits the print from the right angle, and very visible with brighter colors, like white

I don't know what to do anymore.

Anybody got a way to solve this?

Yes sir this is what you do, completely remove the x axis. once you do that, your z rods and lead screws show be completely free. now, Run you Z axis up and down to 100mm at a time using pronterface ( USB connection. you can just use the LCD screen too. but i find pronterface easier.)

WHile the Z axis is moving completely uninhibited by any item on or near it, look closely at each lead screw. Do you see a wobble now? if so, then you have just solved your issue. you need new Z motors with lead screws :).

IF it turns out your Z axis is still completely straight after the removal of the x axis... then i honestly have no clue what i could be. but give that a try and let us know what you find please.