Z-axis drops a little on x-end motor side when off

Posting in general, since while this is happening on a MK2, it's a general enough issue someone may have seen it on a MK3 as well.

While installing the 2.5 kit, I decided to print new PETG parts and do a color change to dress up the printer some. Everything went back together fine, but I'm having 2 issues with the Z axis that seem related to the X-end parts.

The first is, the bearings aren't as tight a fit, and have a tendency to slide out of the x ends. I did occasionally have to push the lower ones back up in my original parts as well, but these are much looser. That shouldn't be too hard to address though.

The more concerning issue is that if I manually turn the z screws to the top to align the x-axis, the left motor side will immediately drop a little bit when I let the screw go. The right will stay at the top.

Now whilst under power, this isn't really an issue, since the z motors are always engaged. My concern is it sliding when off, and having to raise it to the top before every use to align it.

Any thoughts on what could cause this, and how to remedy?

Re: Z-axis drops a little on x-end motor side when off

What happens if you use the Z Calibration (Calibration/Calibrate Z menu) instead of turning the Z axes manually?

Also make sure that no screws have loosened.

Bear MK3 with Bondtech extruder

Re: Z-axis drops a little on x-end motor side when off

Any thoughts on what could cause this, and how to remedy?

I guess it is a combination of too low friction along Z, weight distribution (current X-position of the extruder), and possibly tension between left and right when the axes are aligned (could be caused by the X parts being printed on a printer whose axes are not exactly perpendicular, or by the X and Z axes not being not perpendicular at the Zmax position).

I guess friction could be increased by mounting the lead screw nut a bit differently (slightly tilted?).

But even if alignment is maintained while the printer is off, there is always a chance that the Z motors have been left sitting at an unfortunate position that will make them snap into different quadfullstep positions when the motors are switched on. Such an event would cause an alignment error of 0.16mm (Mk3). One could actually try to work around this via firmware (maybe this is done already?). At detection of low power or reset, the firmware would save the Z position (in terms of microsteps within the electrical motor cycle), and, at startup, set the motor drivers to the saved microstep position before enabling the driver outputs - or park the Z motors in the first pace at the microstep position that is used by the motor driver after reset.

Anyway, it appears to be safest to do a Zmax calibration once in a while.

Re: Z-axis drops a little on x-end motor side when off

I have this problem as well on my MK2 upgraded to MK3. My drop on the x-axis motor side is 2.5mm whenever power is removed or the printer gets reset. I am in the habit now of checking the z height on the LCD before I start a print. If it reads 0 then I know I need to run the z-axis to the top to level it out.

It's not a nut issue as I have moved the nut from the opposite side to the bad side and have the same problem. Been dealing with it for 6 months and haven't found a solution to fix it, yet.

Re: Z-axis drops a little on x-end motor side when off

It's not a nut issue as I have moved the nut from the opposite side to the bad side and have the same problem.

That kinda kills my thought... (a sloppy Delrin hexagonal nut) but it still might be worth checking out just to be sure(?)

I had one so stiff on my MK3 I had to get replacements.

That's "MISTER Old Fart" to you!

Re: Z-axis drops a little on x-end motor side when off

It's not a nut issue as I have moved the nut from the opposite side to the bad side and have the same problem. Been dealing with it for 6 months and haven't found a solution to fix it, yet.

For me, it appears to be related to the delrin nut. I swapped them, assuming maybe the nuts had worn into their respective lead screws. It got much better, but there's still a slight drop.

If I play with moving the nut around a bit, I can get it better still, but not perfect. It's entirely possible it was doing this prior to teardown and I hadn't noticed, but I'd expect I'd have seen it in prints, and I haven't had issues.

I may try shimming one side of the nut to increase tension slightly, I don't want to add too much and introduce print artifacts or binding.

Now to figure out how to keep the bearings from sliding out... I might have to design a little split-ring I can slide up from the bottom into the x ends.

For awhile, I had my start g-code setup to raise the z and square it, since it seemed like a good idea. I took it out because it was a bit of a pita. I may have to put it back.

Re: Z-axis drops a little on x-end motor side when off

For me, it appears to be related to the delrin nut. I swapped them, assuming maybe the nuts had worn into their respective lead screws. It got much better, but there's still a slight drop.

If I play with moving the nut around a bit, I can get it better still, but not perfect. It's entirely possible it was doing this prior to teardown and I hadn't noticed, but I'd expect I'd have seen it in prints, and I haven't had issues.

I may try shimming one side of the nut to increase tension slightly, I don't want to add too much and introduce print artifacts or binding.

Now to figure out how to keep the bearings from sliding out... I might have to design a little split-ring I can slide up from the bottom into the x ends.

For awhile, I had my start g-code setup to raise the z and square it, since it seemed like a good idea. I took it out because it was a bit of a pita. I may have to put it back.

I guess I misspoke. It is a nut issue, but swapping them didn't fix the problem. I have shimmed it with a small piece of paper folded over a few times. It does reduce it some but not enough. Like you I am wary of introducing binding.

As for raising the z in the start g-code to square things up, unless there has been power cut to the printer it is useless with the MK3. Once the z-axis hits 210 it stops and if one side is still lower you will need to turn the lead screw with your hand to level it out.

Re: Z-axis drops a little on x-end motor side when off

I guess I misspoke. It is a nut issue, but swapping them didn't fix the problem. I have shimmed it with a small piece of paper folded over a few times. It does reduce it some but not enough. Like you I am wary of introducing binding.

Yep, definitely nut. I loosened both bolts on the offending side, put an M3 washer under the front, snugged it up, then tightened the back. It was binding a bit too much, so I backed the back bolt off a few turns, and it was just right.

I've run a few prints so far, no issues. Now I just need to remember to keep an eye on it until I trust it's holding.

As for raising the z in the start g-code to square things up, unless there has been power cut to the printer it is useless with the MK3. Once the z-axis hits 210 it stops and if one side is still lower you will need to turn the lead screw with your hand to level it out.

If I recall, the trick was to G28 to set home, then raise to 212'ish to square, but now you've screwed up home, so you have to do another G28, and then the normal start gcode stuffs. That gets you square, and since you're under power, you'll stay square. If it's in your start code, it'll just take a little extra time, but you won't have to worry about it.

I used to do this because it seemed like a good idea to always know you're squared up. But then I stopped because it took time, and I'm impatient 🙂

I may add it back now, I'm not sure I trust my shim, and it feels like I'm just asking to wear out the delrin nut early.

How did you fix it?

Was it a mechanical issue with the delrin nut?

Do you have any preprocessing script for this g28? go 212 in Z and then continue mesh level?

I have had this problem for years, and now when I started this mk2,5 upgrade printer I realised I need to fix this somehow, don't want to continue manually rotate Z to the top after each print.

RE: Z-axis drops a little on x-end motor side when off

A bit of a late reply but since I've seen several people having this problem and no solution I thought I'd post my findings.

I've had this problem ever since I got my first MK3 (my MK2.5 did not have this problem)

I couldn't find any solution so I've always had to move the Z-axis all the way to the top every time the left Z-motor had been without power since the left side of the X-axis dropped down a couple of mm's.

A couple of days ago I started a Bear upgrade on my MK3 and when assembeling the X-axis I noticed the same thing, the left Z-motor dropped down.

I thought I'd swap the right and left side motors to see if that helped, and at first it did, but when I tightened the Z-top parts I noticed the drop again..

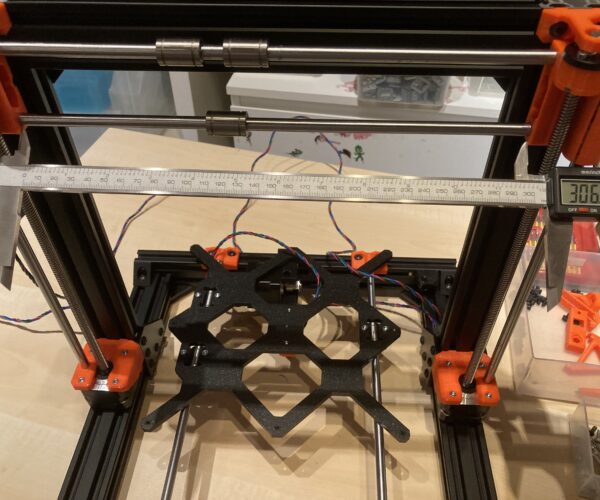

So after doing some testing back and forth I finally decided to measure the distance between the X-parts (the amount of "visible" rods), and that came to 307mm's.

After drilling out the holes on the right side about 1mm I tried again, and now I've got 306,4mm between the X-parts and the drop is gone!

I have to apply a lot of force on the left side to make it drop down, and before with 307mm it dropped down by its own weight, and that is without the extruder mounted, only the X-motor.

So my conclusion is that either my 370mm rods are too long by about 0.5mm, or the X-parts has some defects inside that prohibits the rods from being inserted all the way.