Re: Why is the extruder pulley made of Brass ?

Christian

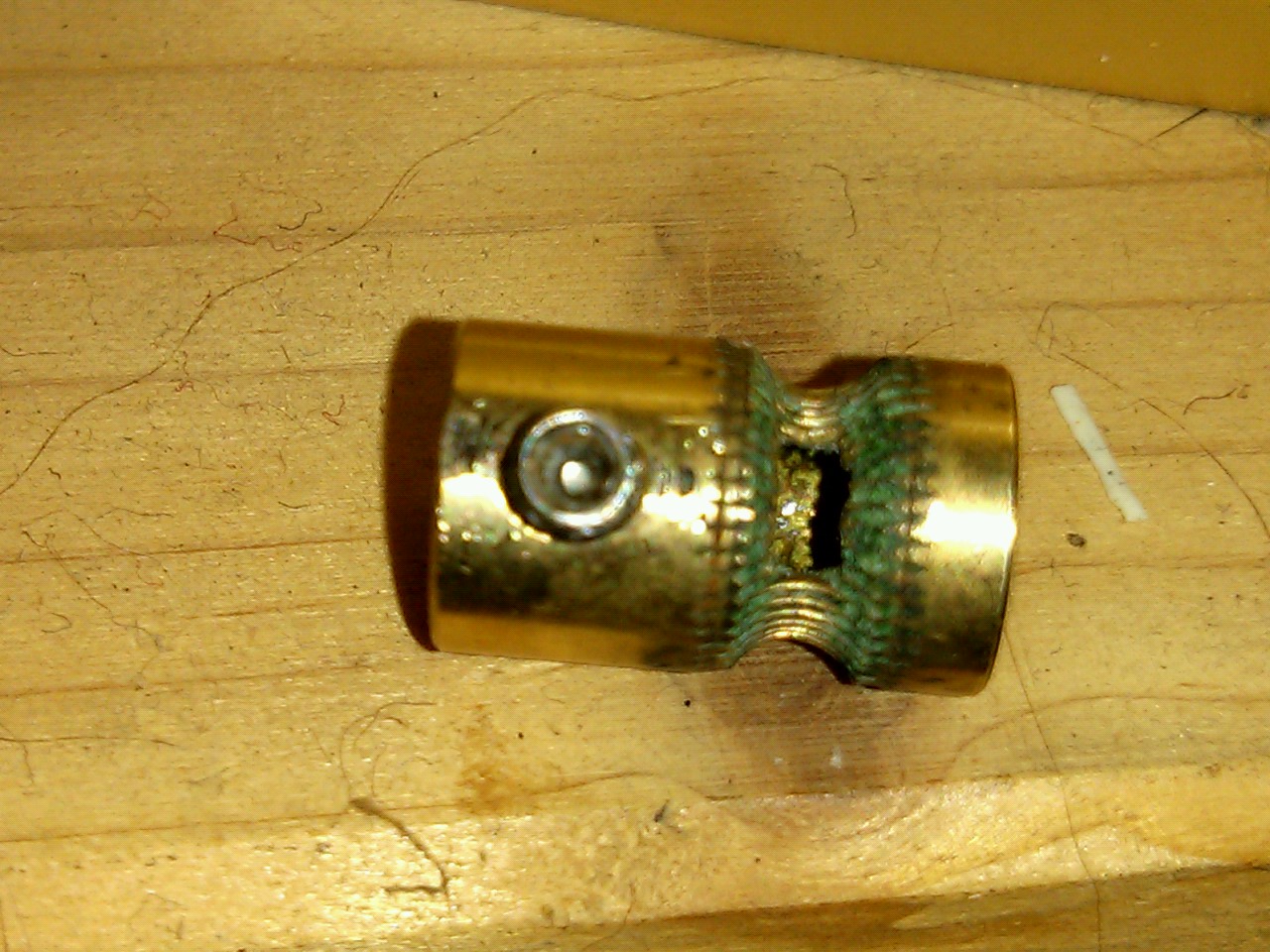

This:

Is usually caused by having the filament tension too tight.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Why is the extruder pulley made of Brass ?

The replacement pulley from Prusa is quite pricey at $13.73 .

http://shop.prusa3d.com/en/mk2-spare-parts/126-mk2-extruder-hobbed-pulley.html

I wonder why these cost more than your average pulley.

There seem to be many much cheaper, similar (but only similar) hobbed pulleys on offer in various internet 3D print shops, some even at half the price for stainless steel versions.

Example: https://www.amazon.com/RepRap-Champion-Filament-Printer-Makerbot/dp/B00THZK97I/ref=pd_sbs_328_t_2?_encoding=UTF8&psc=1&refRID=M9862PDH5QT4T7D1A4JK

Re: Why is the extruder pulley made of Brass ?

Yeah, but its the size that matters.

The Prusa pulley is slightly smaller than the SS ones you will find online (6.2mm vs. 7.5mm) and this causes alignment and feed issues (the latter can be corrected in firmware/GCode but the former requires a redesign of the extruder body).

I did find a cheaper alternative at Oozenest, but it is brass: http://ooznest.co.uk/3D-Printer-Mechanical-Parts/Belts-Pulleys/Hobbed-Pulley .

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Why is the extruder pulley made of Brass ?

Yeah, but its the size that matters.

The Prusa pulley is slightly smaller than the SS ones you will find online (6.2mm vs. 7.5mm) and this causes alignment and feed issues (the latter can be corrected in firmware/GCode but the former requires a redesign of the extruder body).

I did find a cheaper alternative at Oozenest, but it is brass: http://ooznest.co.uk/3D-Printer-Mechanical-Parts/Belts-Pulleys/Hobbed-Pulley .

Peter

Aha, at least an alternative (if it fits, of which I am not quite sure how to tell...).

I've bitten the bullet and ordered 2 from Prusa, and a PINDA probe.

Re: Why is the extruder pulley made of Brass ?

Tech Specs:

Small 5mm Bore

Material Brass

Bore Diameter 5mm

Hobbed Diameter 6mm

Outer Diameter 8mm

Length 13mm

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Why is the extruder pulley made of Brass ?

I was going to order a replacement plus a spare from prusa but the cheapest shipping was $55.00!

This should be a mk8 or something else easily sourced. Why use parts that are impossible to find when this machine is supposed to be "open source" design?

Re: Why is the extruder pulley made of Brass ?

... but the former requires a redesign of the extruder body.

❓ anyone here who could alter the extruder body, so that a commonly used MK7 drive gear (steel) will fit ?

dem inscheniör is' nix zu schwör...

Re: Why is the extruder pulley made of Brass ?

Hi Jeff,

that would open up other issues, for example changing the steps per mm...

the mk7 is a lot bigger than the prusa so your definition would suffer.

a better bet would be to use the mk8 hobbed wheel, which is closed to the prusa hobbed wheel, you would still have to chang the steps per mm, but the definition would be better.... (not as good as a working prusa hobbed wheel...

another option may be, to find someone who can make a stainless hobbed wheel to the prusa dimentions.

or to get a prusa hobbed wheel plated...

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Why is the extruder pulley made of Brass ?

Modifying the plastics, might lead to the extruder plastics colliding with the chassis at extreeme ends of travel.

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Why is the extruder pulley made of Brass ?

I have a probably 20 feet of 1" round 17-4 stainless steel from past projects I've had manufactured. Being that I'm somewhat near the biggest industrial park in the USA it might be worth it for me to find out how much it would cost to machine up a bunch of these extruders hobbed gears. If we had enough people I'm sure I could get it under $25 for the part. Around here machine rates are typically around $100 an hour + 0.5-1 hour for machine setup. If there's interest post here.

Re: Why is the extruder pulley made of Brass ?

With respect, if you were considering making parts... I would suggest that you keep the one inch round material for another project, and buy in some stock nearer the actual required size. because the machine time to reduce the dimensions would probably massively outweigh the cost of the new material.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Why is the extruder pulley made of Brass ?

I would certainly buy a hobbed pulley for $25.- if it was made from steel that will likely last for the life of the printer .

Re: Why is the extruder pulley made of Brass ?

Unfortunately I don't remember where I saw it (too many videos in my youtube chronicles...) but somewhere Josef mentioned that they will be using a different and quite pricey pulley in the multimaterial add-ons. Maybe somebody from the Prusa team can link us to where they are available...

Re: Why is the extruder pulley made of Brass ?

Marc

They are going to be using BondTech drive gears. Unfortunately they won't work with the MK2 without the MultiMaterial setup.

Re: Why is the extruder pulley made of Brass ?

With respect, if you were considering making parts... I would suggest that you keep the one inch round material for another project, and buy in some stock nearer the actual required size. because the machine time to reduce the dimensions would probably massively outweigh the cost of the new material.

regards Joan

You'd be absolutely correct. I just checked and the material cost would only be about $1 each. It all comes down to machine time use being split among multiple pieces making them significantly cheaper than doing only a few.

Re: Why is the extruder pulley made of Brass ?

Thanks Richard for the link.

Unfortunately they won't work with the MK2 without the MultiMaterial setup.

...pitty... 😥

Re: Why is the extruder pulley made of Brass ?

I would be in for a SS pulley that can be sourced in the USA.

Re: Why is the extruder pulley made of Brass ?

So this one does not fit ?

http://e3d-online.com/Extruders/Hobb-Goblin-5mm

There is no valid alternitive somewhere ?

E3d seem to think it'll work, this was their reply when I asked about it;

"This will fit, however the effective drive diameter may differ slightly. You will need to re calibrate your e-steps, but other wise it is just a drop in replacement with no firmware changes or the like needed."

It's a shame they don't have any stock.

Re: Why is the extruder pulley made of Brass ?

Yeah, but its the size that matters.

The Prusa pulley is slightly smaller than the SS ones you will find online (6.2mm vs. 7.5mm) and this causes alignment and feed issues (the latter can be corrected in firmware/GCode but the former requires a redesign of the extruder body).

I did find a cheaper alternative at Oozenest, but it is brass: http://ooznest.co.uk/3D-Printer-Mechanical-Parts/Belts-Pulleys/Hobbed-Pulley .

Peter

I just received a few of these from Oozenest, they came with a bunch of set screws and an allen key. I asked for extra set screws, so I'm not sure how many they usually pack, but each of mine has 8 or so set screws included.

Re: Why is the extruder pulley made of Brass ?

I stripped the threads on my brass pulley during my first build. One fix that worked (temporarily) was to drill and tap a new M3-0.5 hole on the opposite side from the existing stripped hole. I reinstalled the pulley using the set screw in the new hole and applying medium strength thread locker to the set screw. This worked for one day and then the set screw stripped itself out again. I found the set screw inside the extruder with the new threads stripped again.

I have ordered the stainless steel replacements. When they come in, I plan on turning down the hobbed radius on a lathe for the proper diameter and then cutting grooves in the new "gear" surface with and end mill.