SOLVED - How to fix the hole in my heat bed

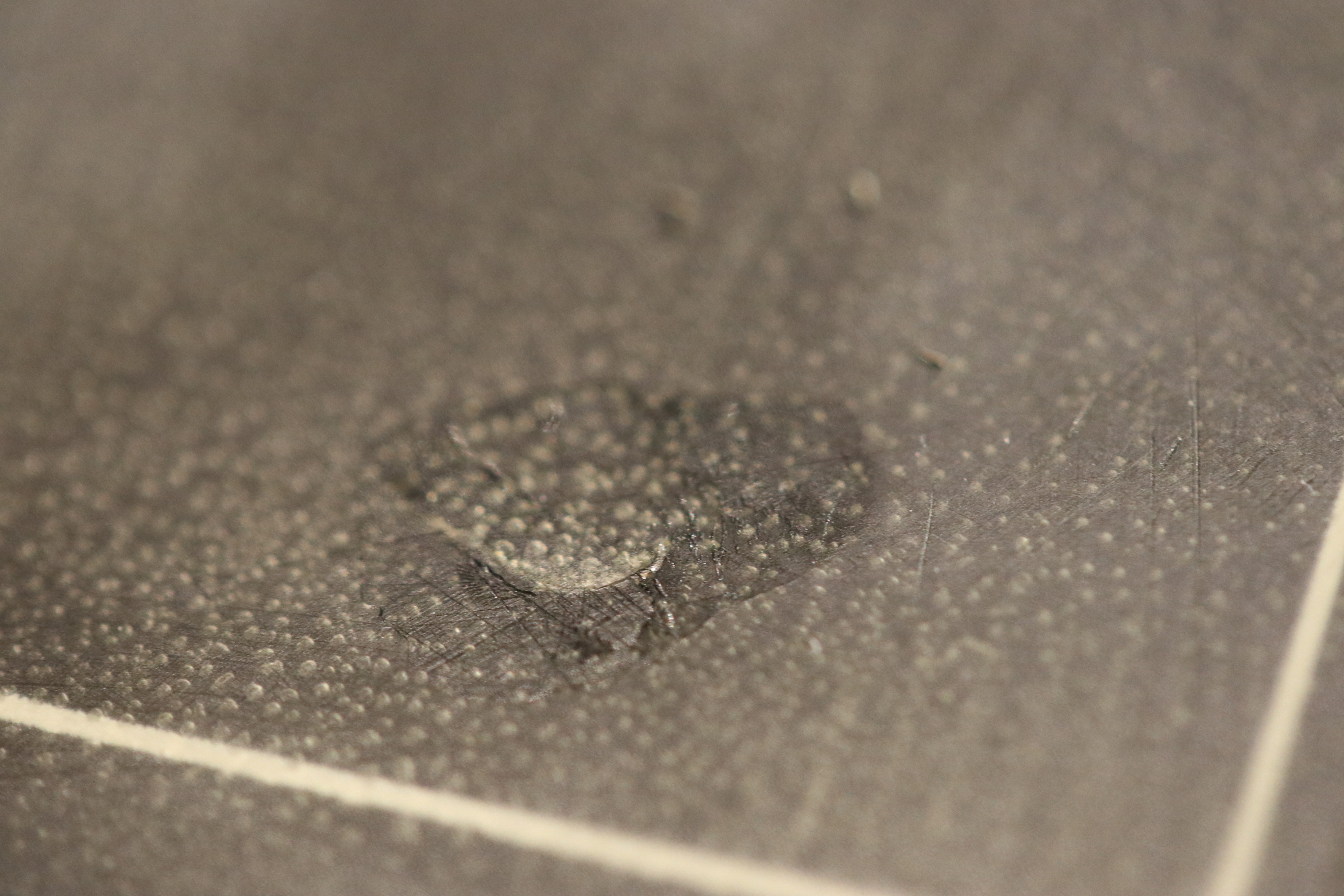

During the calibration I made a beginners mistake causing the nozzle to create a hole, or indent into my heat bed. Not the biggest problem as its not in the middle.

I am currently busy replacing the Pei sheet, so I though, good moment to ask this question, is it possible to fill the hole up with something? Just like you would do with a hole in the wall? What kind of paste should be used, if any...

[

Re: How to fix the hole in my heat bed

If I may ask what did you do to cause it to crash? Another question for the experienced crowd, what do you do to prevent these kind of mistakes?

Re: How to fix the hole in my heat bed

Not exactly what you are looking for but perhaps a starting point. I managed to cut my pei with a blade when removing a print(top cut with a flap) and after some research used ethyl-2cyanoacrylate(loctite superglue in my case) to glue it back. I sanded the excess and while it won't last years I have printed many times over it. If I understand that your hole is under the pei then as long as you can offer some support and bonding and the hole is not more than 2 to 3mm then I think the same approach might work. There are others far more knowledgeable than me on this forum so I will stand corrected. Longer term I am not worried as the 2.5 upgrade will make it a moot point for me.

Rory

Re: How to fix the hole in my heat bed

Just replace the PEI.

The damage should only be to the PEI sheet. If there is damage to the bed underneath and it is sub flush then ignore it. Look at the screws in the bed the PEI sheet bridges over the holes in those.

Re: SOLVED - How to fix the hole in my heat bed

I am very confused, I removed the Pei sheet, hole was still there.

Removed the glue using turpentine, repeated 3 times and now the hole seems gone... strange... I am sure the hole was also in the bed itself, I could see and feel it.

Heres the image from a cleaned heat bed, without pei sheet