Instructions for replacing PTFE tube

I was trying to follow along with the instructions for replacing the PTFE tube (the web-based instructions in the English manual section of the Prusa web site), and suddenly hit a wall. Do I take it the instructions there are for the Mk1 machine? I bought the Mk2 kit--are there any instructions for replacing the tube on the newer model?

The instructions show the new tube being run clear through the heater cooling fin section, and getting trimmed as it comes out the other end. However on my unit the brass piece on the heater end of it has an inside diameter way too small to allow the tube to come out through.

Re: Instructions for replacing PTFE tube

Hi John,

these Generic E3d V6 assembly instructions may help

http://wiki.e3d-online.com/wiki/E3D-v6_Assembly

I understand that you first cut the end of the new PTFE tube, absolutely square to the bore of the tube,

if you get a small allen key and feed it into the top of the heat-sink, you can estimate the length of PTFE tube required to pass through the heat-sink and into the heat-break tube...

if you can mark this length onto the PTFE, you can check when you insert the PTFE, that the end is firmly inserted into the heat-break tube

when you have inserted the PTFE tube, you are supposed to try and pull the black retainer ring away from the heatsink by a short distance to reduce the chances of the PtFE tube moving after installation.

regards joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Instructions for replacing PTFE tube

Thanks Joan!

That article was helpful, if for nothing else than to just assuage my fears that I was on the verge of screwing everything up.

One thing I noticed about the tube that was originally in my printer, and that was that the end down by the heater block was beveled at about a 45 degree angle at the end. I didn't see anything about that on the E3D site, but I figured the replacement tube should be as close to the original as possible, so I used a little pencil sharpener (little stainless steel thing I use to sharpen my drawing pencils) to bevel that edge. Don't know if it made a difference, but it looked just like the original. And now the printer is humming along--I'm back in the running!

Another thing that came to me as I was cutting the PTFE tube to length, was that with the tube not able to come out the opening, it was hard to get a perfectly straight/perpendicular cut on the tubing. I think I am going to try to come up with a little cutting guide and print it out--something that will guide my exacto blade perfectly straight down through the tube.

Thanks again,

John

Re: Instructions for replacing PTFE tube

And now the extruder appears to be blocked again. I've tried manually advancing the extruder and the filament is jammed in the tube. I got one and a half days of fairly good printing since the last overhaul. The "up cycles" just seem to be getting shorter and shorter. And I didn't even change spools this time! This is all just one material. I'm getting so sick of having to take the extruder carriage apart and unclog the PTFE tube. I just cannot figure out what I am doing wrong--I am getting so envious of everyone who says their machines just crank like champs for days on end. 👿

Re: Instructions for replacing PTFE tube

John

What retraction settings are you using?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Instructions for replacing PTFE tube

What retraction settings are you using?

I've never touched those, so I guess they are the Slic3r defaults:

Length = 1.5mm

Lift Z = 0

Only Lift Z (above Z = 0) (Below Z = 0)

Speed = 30 mm/s

Extra length on restart: 0 mm

Minimum travel after retraction = 1 mm

Retract on layer change = SELECTED

Wipe while retracting = NOT_SELECTED

Then below

Retraction when tool is disabled...

Length = 3 mm

Extra length on restart = 0 mm

I'm not familiar with retraction or the function of it. Is this something that happens at the end of each print--that it backs the filament back out, or when you select "Unload Filament"? And if it retracts while hot, wouldn't it just stretch the PLA material in the nozzle? I would certainly appreciate any insight you could share here. I'm really flummoxed.

Re: Instructions for replacing PTFE tube

John

Retraction helps prevent oozing and stringing during non printing moves by releasing the filament pressure in the nozzle.

However, too much retraction can lead to blockages.

I believe that the later releases of Slic3r profiles have retraction set to 0.8mm, because of blockages caused by the earlier 1.5mm retraction.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Instructions for replacing PTFE tube

John

To expand a bit more...

If the end of the PTFE tubing is not exactly square and is not tight up against the stainless steel heat break, then too much retraction causes the filament to solidify in the gap between tube an heat break, which in turn causes blockages.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Instructions for replacing PTFE tube

This brings to mind something related that has always puzzled me. When taking the extruder apart I always see it said that I should take the opportunity to completely clean the nozzle out. Well, I've been printing primarily with PLA (because supposedly easier to print with, and because I would get a thermal runaway error every time I tried to reach higher temps needed to print ABS), and I have found it impossible to clean the nozzle out. I've tried the torch method, soaking in acetone and then the torch...I can get some material out but never all of it. (I'm beginning to think I should try working with ABS again, as it is my understanding that soaking the nozzle clogged with ABS in acetone overnight will completely dissolve it sparkly clean--is that true?).

But the thing is, does it really matter if you get the nozzle unclogged? Doesn't the nozzle get clogged anyway the minute you turn off the power after a print? Or does the retraction pull it back after it is partially cooled so that when the machine powers down the nozzle would be unclogged? It just seems to me that the nozzle is clogged after any print, as soon as the plastic cools...and that all that plastic inside the nozzle simply liquifies the next time you heat it up, and then flows out. Or am I missing something?

Re: Instructions for replacing PTFE tube

If the end of the PTFE tubing is not exactly square and is not tight up against the stainless steel heat break, then too much retraction causes the filament to solidify in the gap between tube an heat break, which in turn causes blockages.

Oh dear...I bet that has happened. I say that because this time I pulled the extruder carriage apart, and usually I can unscrew the cooling fin and heat break out of the block, but now I cannot. I suspected that some plastic material has cooled and is holding the heat block fast. (Though I could have sworn I got the PTFE tubing really square--but then I beveled it. So maybe that beveling is creating the space that is getting filled with plastic? And since the original PTFE tubing had the same beveling, that is why my printer has been clogging so much since day one?)

I was thinking of partially engaging the heater so as to soften the plastic, so that I can unscrew it, but how do I get the plastic out of the heater block now?

And I am definitely going to try reducing the retraction to 0.8 to see if that helps. (Assuming I can ever get the machine printing again!)

Re: Instructions for replacing PTFE tube

John

When assembling the extruder I do the following:

Screw heat break into heat sink (with thermal paste applied.

Unscrew the heatsink half a turn

Insert the ptfe tubing and while pushing down, lock in place by lifting the black ring.

Tighten the heat break in the heat sink - this ensures a good seal between the two.

Insert nozzle into heater block

unscrew nozzle half a turn

Insert assembled cold end into heater block

Heat to 240 degrees and tighten nozzle.

Yes, the nozzle clogs when the heater is turned off, but the clog will melt again on re heating. Any soft filament drawn back into the gap between heat break and PTFE tube will harden there and will not re-melt because it doesn't get hot enough.

Best way to clean the nozzle with PLA is the Ultimaker "Atomic Method" which is basically a cool pull (90 to 100 degrees). Personally, if that doesn't work, I change the nozzle.

Lower retraction and your clogging should disappear.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Instructions for replacing PTFE tube

I am currently in the midst of attempting to clean the burnt plastic out of the heater block and off the threads of the heatbreak. I have downloaded the latest Prusa software kit, which has the latest version of Slic3r for the Mk2, complete with the 0.8mm retraction setting, as well as any other parameters that might have been modified (I like that there is a 0.15 Optimal setting now), so I am confident that if I am able to get it printing again, I should be able to keep it running longer between down-cycles. And if I can't get this one cleaned out, at least a new heater block is not terribly expensive.

I just wanted to take this moment to thank those who responded to this thread, and especially to you, Peter--your posts and explanations have resulted in a HUGE leap in my understanding about the processes going on, allowing me to determine the best procedures both for clearing this present jam and also moving ahead in the future. The more I understand, the greater my confidence will be moving forward--so I truly appreciate your help. I will do my best to pay it forward on the board here, whenever I see someone new coming along that falls into the same pitfalls I did--I will try to help them out. It's pretty easy to see that one of the best things about this printer is the community of humans who operate them, and their ability and willingness to share information.

Re: Instructions for replacing PTFE tube

John

Pleasure to be of assistance and thank you for your kind comments; at least one person appreciates my input 😉

Your attitude towards this forum and its users is the reason why I am here, being a relatively early member and having both the Mk1 & Mk2 printers along with a Chinese clone (which was my first printer and is now very rarely used).

Interesting times ahead with the new multi-filament upgrade about to be released, but I think that will be for experienced users initially...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

RE: Instructions for replacing PTFE tube

I have replaced the PTFE tube on the MK3S with original spare part that came with the printer.

following the instruction it is said to push the PTFE to the very end of the hot end and then lock it in place with the black ring.

Doing this the PTFE sits fairly low in the hot end, about 10 mm are sticking out.

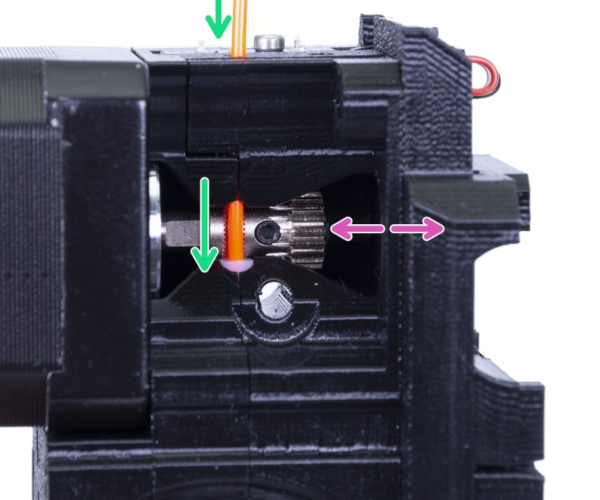

On the other hand in the extruder assembly it is visible that the PTFE tube from the hot end is sticking out some 0.5 mm near the bondtech gear and it is visible from the side of the idler (when door is open)

With original PTFE lenght pushed into hot end this is impossible.

Here below the view from the manual , in my case the white ring of the PTFE tube (near the tip of the big green arrow) is not visible as it is far below into the black assembly.

Anyone has a clue what is right ?

thanks!

Vale