Have tried everything

We have a Mk2 that has been reliable for years. We have replaced the typical parts, but have run into a problem that we can't solve.

We are unable to get beyond the first layer before the extruder begins clicking and stringing. We have replaced the hotend, the nozzle, the extruder stepper motor and any parts that might be liable to clog. we have tried multiple rolls of filament. We have the most recent firmware and have re-sliced every print we've tried.

There just doesn't seem to be anything left to try.

Any ideas???

.

Have you tried adjusting the pressure on the extruder idler?

Cheerio,

RE: Have tried everything

yes, early on, and again when we replaced the stepper motor thinking the old motor was underpowered

.

Can you show us a picture of the stringing part of the problem, of the nozzle assembly, and of the surface of a failed print?

Cheerio,

RE: Have tried everything

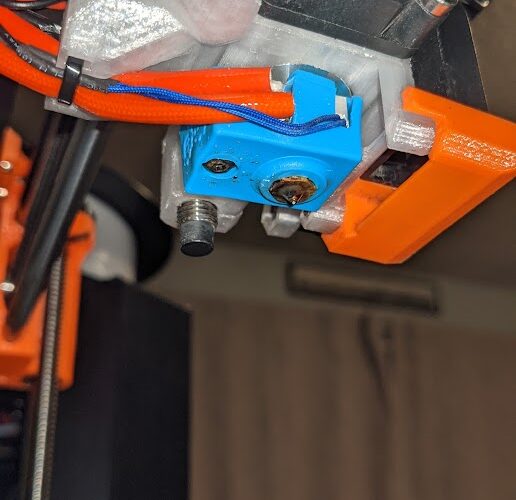

Just to clarify, this is a MK2S. Here is the nozzle assembly:

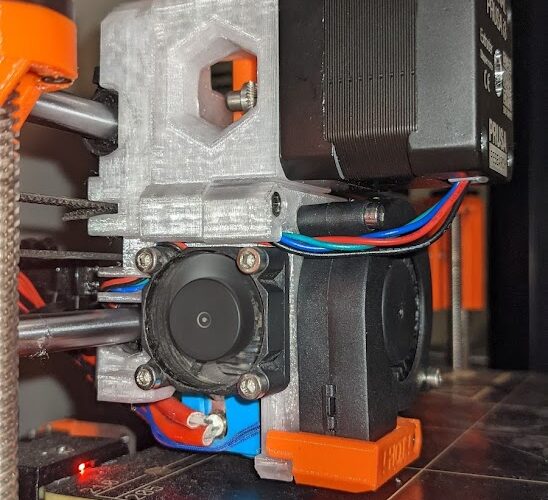

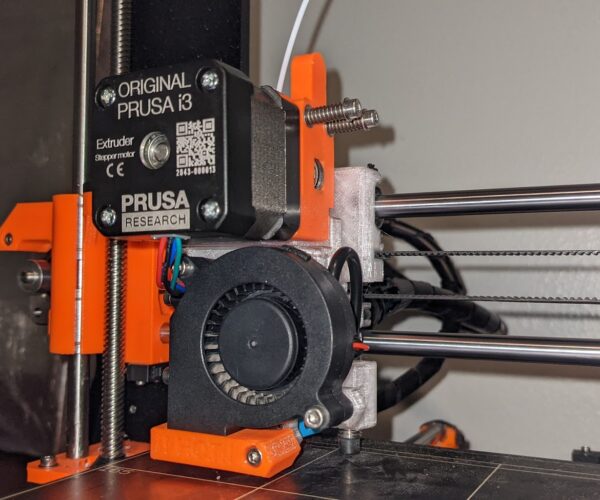

Extruder assembly:

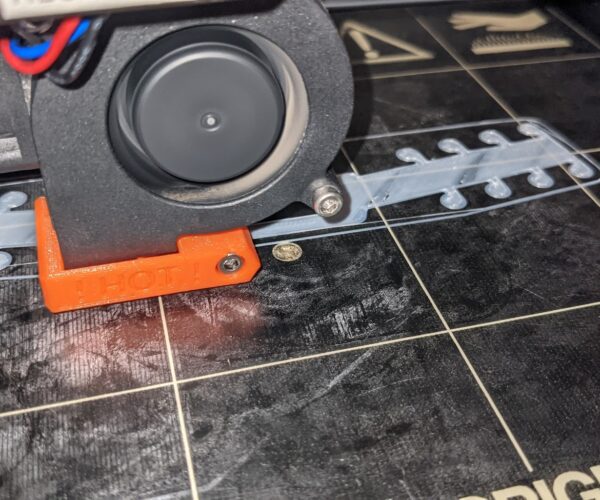

The start of an example print in PLA. At the start of the first layer, everything was fine.

These little gaps are where it clicks once or twice, but otherwise the first layer seems okay.

As soon as the second layer starts, the PLA lays out super loose, barely connected to the first layer. The clicking sounds like a drum cadence throughout the rest of the print.

Below begins the third layer, still constant clicking and very stringy, loose layers.

Final result, terrible stringy print. This is the result with other filament and model that I have tested with.

.

No glaring errors there - which is annoying ....

If you had not already swapped the parts I would be suggesting a cold pull and adjusting the idler pressure, also looking for filament dust clogging the gripper.

The stringing doesn't look like damp filament 'though it's always worth drying it. It looks like interlayer adhesion is somehow intermittent; what layer height are you printing at?

The stuttery fill is typical of poor extrusion and correlates with the rapid clicking you describe. Again a cold pull and idler pressure issue...

Raise the nozzle, disengage the idler, preheat to working temperature and push some filament through by hand.

Does it go through without difficulty and does the extruded filament come out straight and even in thickness?

Cheerio,

Quick question to answer the obvious

In addition to speed changes, the biggest change going from layer 1 to higher layers is cooling. If you disable or reduce cooling, is the clicking as apparent? I see you have a silicone sock mounted, but that fan does look like it's blowing right on the block (at least that's how it looks to me). Misaligning the fan during reassembly could account for this. Also, since you replaced the hotend, did you do a PID tune?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

.

Sharp eyes @bobstro, you may have something there...

Cheerio,

RE: Have tried everything

I had cold-pulled and adjusted the idler before with no progress, unfortunately. I had initially thought that it would be a filament problem, so I had dried them as well. This test print was at .35mm layer height, but the same thing occurs with finer heights as well. You bring up the idea of disengaging the idler to see if I can manually push the filament through, and yes, I can. It seems super odd that I can do that as well as load/unload filament perfectly fine with no clicking whatsoever.

RE: Have tried everything

I tried to make sure that the fans are mounted correctly, and it looks normal at least to me. How would you go about disabling the cooling safely without damaging the extruder assembly? (As you can see, I have replaced some of the printed parts of the extruder assembly due to a cooling error before, so I'd like to go about this as carefully as possible.) And, to answer your question about whether I did a PID tune after replacing the hotend, yes I did. Everything was working fine after replacing the hotend for a while.

Just disable cooling in slicer

[...] How would you go about disabling the cooling safely without damaging the extruder assembly?

Just set cooling to 0 in your slicer and create a test print gcode file. You could remove the fan or duct, or just point them away as well. Nothing fancy is needed.

(As you can see, I have replaced some of the printed parts of the extruder assembly due to a cooling error before, so I'd like to go about this as carefully as possible.) And, to answer your question about whether I did a PID tune after replacing the hotend, yes I did. Everything was working fine after replacing the hotend for a while.

At this point, please save your current 3MF project file, zip it up, and attach it to a reply here so we can see your part & settings and give better recommendations. I (and others I'm sure) would like to see what is different in terms of settings between your 1st and subsequent layers.

If this is something that only recently started, it is unlikely to be settings. I'd run a self test and try without cooling to see if the 2nd layer flows more smoothly. The printer itself doesn't "know" it's printing any particular layer, so it's a question of figuring out what triggers this odd behavior.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

.

0.35mm layer? Is this a 0.4mm nozzle?

If so it might explain this pattern of loose stringing; if the layers are not being squished together so tightly. OTOH it doesn't sound like back pressure from close layers is likely.

You didn't say how the manually pushed filament emerged, I presume you would have mentioned if it curled or swerved to the side so your nozzle is probably OK too.

The clicking is the printer losing its grip on the filament, slipping, and taking another grip. Usually this is due to pressure from, eg. a blocked nozzle, sometimes the idler pressure is off and it slips at normal filament pressures.

Often this gouges the surface of the filament and the consequent dust can clog the gripper, reducing its function...

A blast of air into the filament path or a dusting with a stiff paintbrush might be in order.

Wild thought: How is your filament spool mounted? Is there tension working against the extruder?

Cheerio,

RE: Have tried everything

Wouldn't turning all of the cooling off cause the hotend to damage the extruder housing? I'm just worried about stuff melting. Here's the STL and GCODE I've been testing with. As I've previously mentioned, though, I have tested with many other models.

RE: Have tried everything

Gcode:

RE: Have tried everything

Wouldn't turning all of the cooling off cause the hotend to damage the extruder housing? I'm just worried about stuff melting. Here's the STL and GCODE I've been testing with. As I've previously mentioned, though, I have tested with many other models.

The hotend cooling fan stays on. You can turn off the part cooling fan that blows below the nozzle. They are independent.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan