.35 Fast Poor Layer to Layer Adhesion

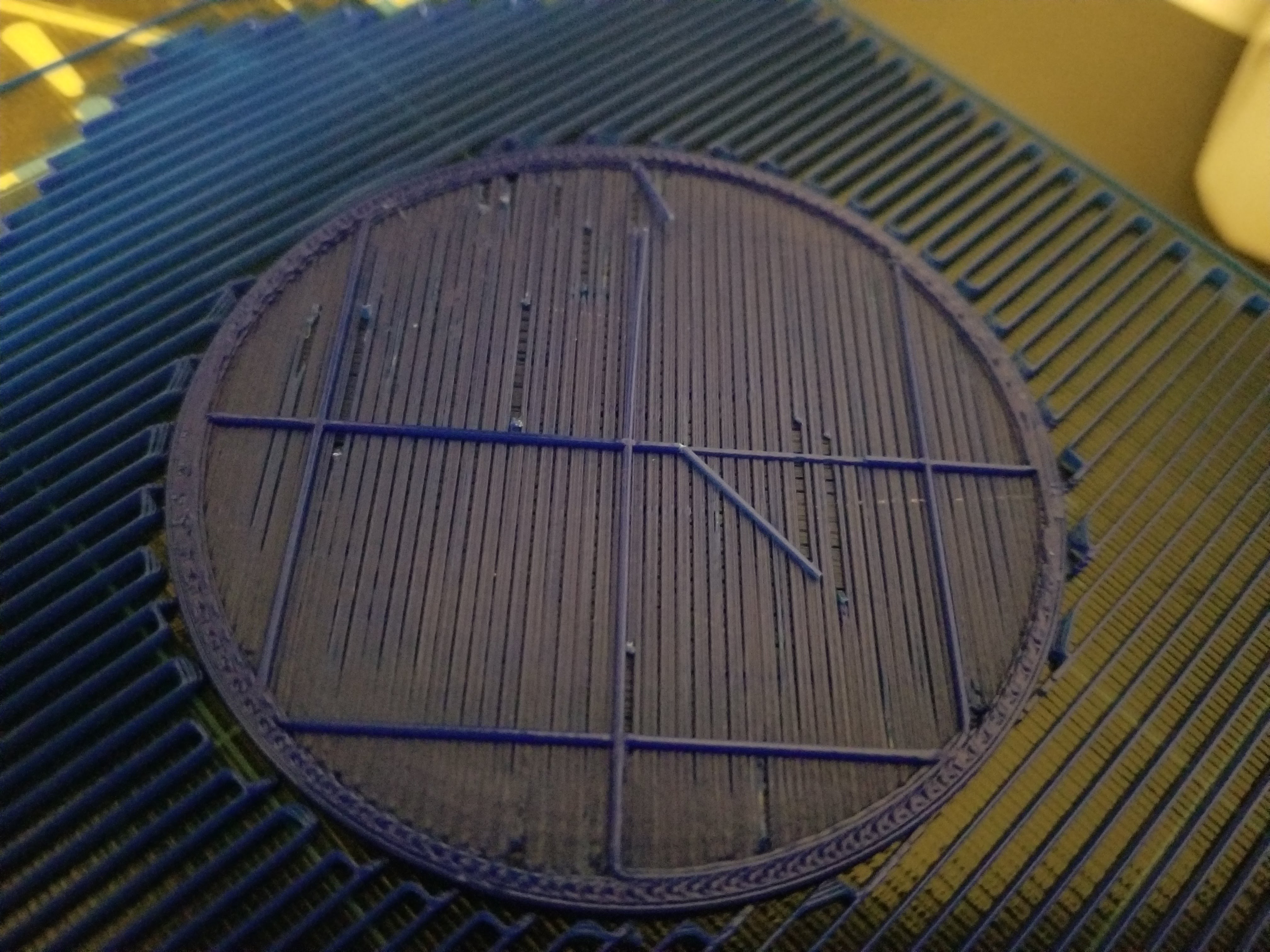

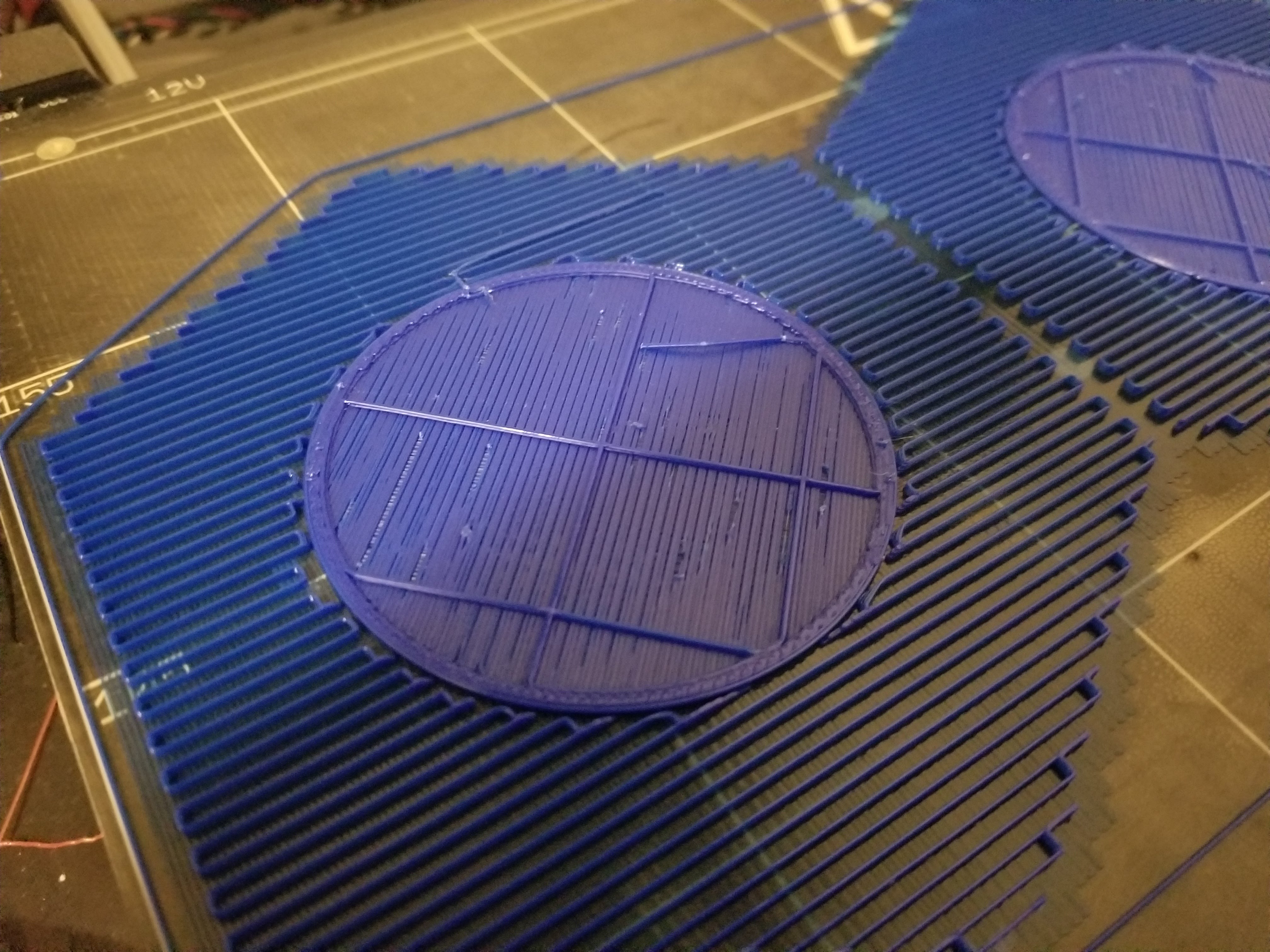

I recently attempted to print using the fast 0.35mm layer height setting. I adjusted the speeds to match those of the default 0.2mm linear advance, which may be the problem. Within the first 5 layers I saw my layer to layer adhesion was terrible. It reminds me of a 1st layer with live z too far away from the bed. The solid layers had gaps and strands of filament sticking up, and the infill wasn't adhering to itself. Are my speeds the culprit, or is something else going on?

Re: .35 Fast Poor Layer to Layer Adhesion

Hi Chris,

you haven't given us information on your print settings.

we cannot confirm or deny what the problem might be.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: .35 Fast Poor Layer to Layer Adhesion

skipped steps or not hot enough for that layer height/speed or maxing out the v6's flow rate....

Re: .35 Fast Poor Layer to Layer Adhesion

I assume you're trying to print 0.35 layer height with 0.4 nozzle. It doesn't work (that simple). I will not push you to the "tricks"-section how it might work.

Go the standard route and use at least 0.6 nozzle for this layer height or go 0.2 layer height max.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: .35 Fast Poor Layer to Layer Adhesion

I assume you're trying to print 0.35 layer height with 0.4 nozzle. It doesn't work (that simple). I will not push you to the "tricks"-section how it might work.

Go the standard route and use at least 0.6 nozzle for this layer height or go 0.2 layer height max.

eh... 0.35 is a slicer profile for mk2/s and it has worked fine when i tried it... except maybe infill extrusion width and speed was a bit aggressive and just caused skipped steps for me on some models. however i always used 0.3 anyway with S3D. But it's part of the slicer profile so its probably his speed settings.

Re: .35 Fast Poor Layer to Layer Adhesion

eh... 0.35 is a slicer profile for mk2/s and it has worked fine when i tried it... except maybe infill extrusion width and speed was a bit aggressive and just caused skipped steps for me on some models. however i always used 0.3 anyway with S3D. But it's part of the slicer profile so its probably his speed settings.

Just read some articles like this or like this

Maybe you will start to understand why it's a bad idea to go higher then 0.2 layer height with the 0.4 nozzle. 🙂

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram