Impossible mesh bed leveling (mbl), mbl correction not enough to counter PINDA/skewedness

Dear folks,

over time I have developed either a skewed heatbed, or an consistently incorrect working PINDA probe. The rear-right side is roughly 0.2 to 0.3 mm lower than the front-left side (if not more). Additionally I have some 'wavey' spots on the left side which might stem from re-applying a new PEI sheet or prints that were harder to get off. (These spots can be avoided here and are not my issue here). I am also not trying to print overly large items, but the difference in height makes it near impossible for me to get a consistently flat first layer (0.15 mm first layer height, 0.1 mm other, 0.25 mm nozzle at 0.3 mm width).

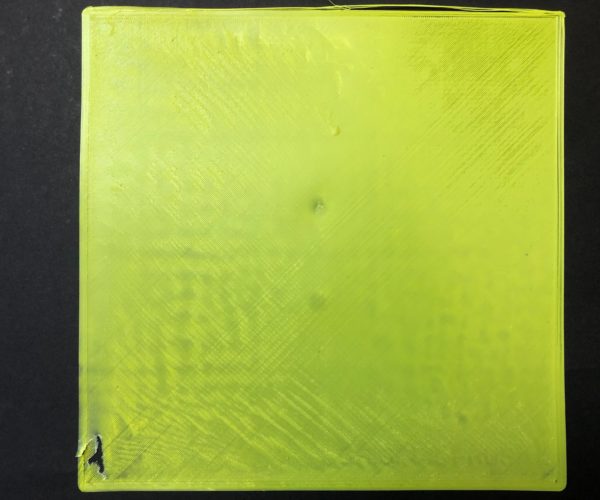

Printed the first layer (0.15 mm height) across the heatbed and this is what it looks like:

The top right hand corner is so far off that the layers even seperated, especially the 4 mm brim. I already adjusted the rear and right side by 50 microns closer to the nozzle via mesh bed level correction, but it's not enough. I flashed the newest firmware, but sadly I can't still only go +-50 on each side. I am certain that there is no air trapped underneath the PEI sheet as that would be easily visible.

Any suggestions on what to do? Replace heatbed alltogether? Replace the PINDA probe (but it is so consistenly wrong so I dont suspect the PINDA here ...)

Best

Dom

RE: Impossible mesh bed leveling (mbl), mbl correction not enough to counter PINDA/skewedness

Hi Dom,

the Mk2 Pinda is not temperature compensated in any way, so that can cause complications...

and the frame is a little prone to twisting...

I would suggest that first of all you put the printer on a flat surface and see if all four feet are touching the work surface.

the frame should not rock if you press firmly on each of the frame corner posts in turn...

if the frame is twisted two of the feet will be firmly on the work surface, and the other two will touch, depending upon which way the frame is moved.

in order to correct this easily, put a couple of coins under the front corner post that is touching the ground firmly (this should make the amount that you can rock the frame worse...)

now press firmly on the two corners that are not touching the work surface, This action should introduce a small controlled twist into the printer frame, hopefully correcting, or partially correcting the twist...

remove the coins and re check for twist. (frame rock / wobble)

if this was not enough to correct the problem, try again with three coins... etc.

next re adjust your mesh bed levelling...

I suggest you start by noting the bed level correction settings, then resetting them to zero

raising your extruder to about 60mm above the printbed, to reduce the heating effect of heatbed proximity. then,

readjust your live Z for the middle of the bed, using Jeff Jordan's 'Life adjust Z, My Way'(there are three zipped files at the bottom of the first post in the thread, containing sample files for adjusting Live Z, at PLA, PETG and ABS temperatures)

Once this is complete, check for first layer print quality at the sides and corners, adjusting the bed level correction variables as needed.

please lift the extruder to about 60mm above the bed before starting any prints, so that you get a bit of consistency in the pinda probe tests.

when complete, check your old bed level correction settings against the new ones, see if there is a big difference.

if all else fails, the Mk2.5 upgrade introduces a temperature compensated pinda probe and 7x7 mesh bed levelling, with a new mk52 12volt magnetic heatbed and a removeable build plate, whick is an immense improvement...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Impossible mesh bed leveling (mbl), mbl correction not enough to counter PINDA/skewedness

@joantabb

Thanks for your reply. The frame did indeed rock. Strange since the printer thought it was perpendicular. Havent had the chance to fire the printer back up, but I am not sure how long that kind of a „fix“ will solve my issue before the frame is re-bent. I also checked the heatbed with a ruler and it appears to be approx 1 mm lower in the middle part than on the front and back. So it might really be a culmination of issues ... will report back. Thanks!

RE: Impossible mesh bed leveling (mbl), mbl correction not enough to counter PINDA/skewedness

So I made sure the frame is not rocking anymore, re-applied the zip-ties that hold down the metal rods, made sure no screws are lose, re-did the xyc calibration (result: Perpendicular as it has always been ...). The attached picture shows the problem of the first layer with a 0.25 nozzle. This one might stem from the heatbed being skewed (would make sense since a ruler does not touch the middle of the heatbed along the y-axis. But in theory, the Pinda should be able to adjust something like that?

Oh and by the way I always pre-heat the nozzle at the top of the z-axis to minimize heat issues regarding the pinda. Any suggestions going from here? Thanks!

RE: Impossible mesh bed leveling (mbl), mbl correction not enough to counter PINDA/skewedness

bump

RE: Impossible mesh bed leveling (mbl), mbl correction not enough to counter PINDA/skewedness

What would solve my problem is if I could adjust the firmware to allow for more mesh bed level correction, 50µ just wont cut it. 100 or 150 per corner would be preferable. Any idea how I could go about to do that?

RE: Impossible mesh bed leveling (mbl), mbl correction not enough to counter PINDA/skewedness

I don't own a Mk2, but this article looks like it might be helpful. Good luck with it.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Impossible mesh bed leveling (mbl), mbl correction not enough to counter PINDA/skewedness

Quick Update:

I took the plunge and invested in a MK2.5s upgrade. I didnt think it was possible, but it made things even worse. Now I am having constant issues with "some problem encountered, z-leveling enforced". Always in one of the rear spots of the printer. 9 out of 10 times, the error happens and if it does go through, it does so only very hesitantly in said spots. Happens regardless of 3x3 or 7x7. The prints (if they do start) are actually fine but the printer - as it is now - is unusable. Support from Prusa is sadly also a bit slow to answer and I am not sure what to to at this point. Use an older firmware maybe? (using 3.8.1 right now)

Oh and the filament sensor is not working properly either, but I havent checked the wiring yet.