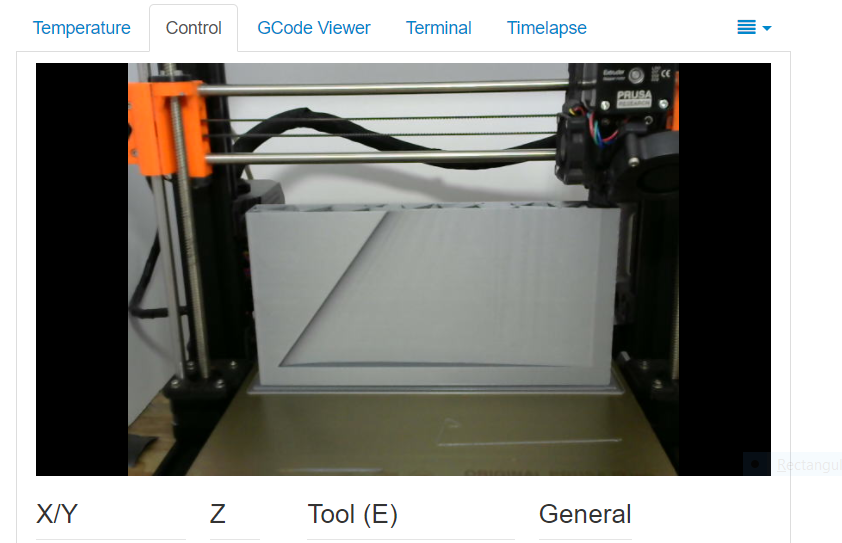

Prevent this part from warping?

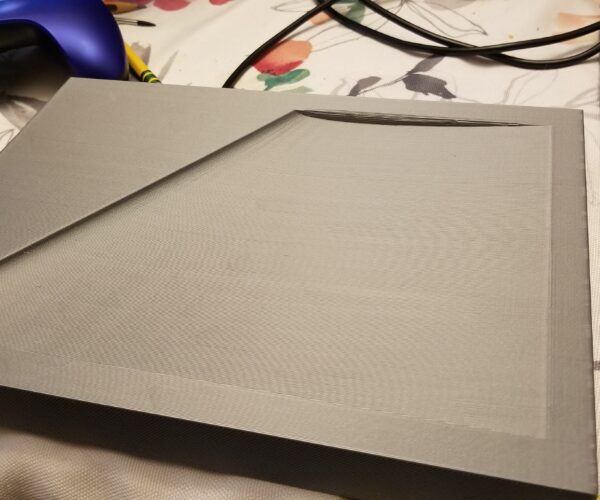

I could never get PLA to stick well enough to the printer, so I switched to PETG without using a glue stick, and sure enough, it held! HOWEVER, this part had so much force in warping that I believe it was bending the build plate. The PEI on the smooth sheet even shows signs of it starting to separate from the base metal. I need these prints to have a flat bottom. These will be molds for fiberglass and carbon fiber wings for my airplanes.

This isn't an issue with first layer adhesion obviously, but more to do with print design to mitigate the warping. I suppose I could try thin wall printing and doing custom fill, and removing the angle on the side. Printing these laying down does not offer the resolution I would like.

RE: Prevent this part from warping?

I cant really help with settings for warping, but one solution could be to make them just a tiny bit oversized and sand them down to flat surface with wetsanding.

Or try the smaller side down to plate with a brim.

Also, consistant temperature around the bed with absolutely no draft also help as the plastic cools more slowly.

Are the parts solid? Maybe hollowing them out with a 5-10% infill with 2-4 walls instead could work as there are less plastic to contract.

Prusa Mini+ kit. BondTech extruder. FW 5.1.2

Prusa MK3S+ kit. Stock. FW 3.11.0

Prusa MK3S+, used. Stock. FW 3.13.3

RE: Prevent this part from warping?

@prus-38

I've since built an enclosure to remove draft and keep the heat in and have switched to 2 perimeter walls. Going to create my own infill much like what the 3DLabprint people do with their airplanes.

RE: Prevent this part from warping?

Ok, looks like with a raft, and some changes to the print, such as making it deeper, adding a border to the top and bottom, getting rid of the angle on the side, and using a raft in combination with the heated chamber, might have a winning combination here.

RE: Prevent this part from warping?

I note you have fixed the problem. But one comment, having been through the same process. The model fan on the M2.5 is much more efficient than on the Mk2, and I found I needed to turn the fan speed down in the slicer cooling setting to 30-50%, else the hotend would not hold temp. When the fan starts up after the first couple of layers ( by default at 100% speed ), it cools the part, which makes it shrink. Setting it to 50% or even less, just enough so thin walls get a chance to set before the next layer, remarkably improves the warping.