X axis end stop triggered too early

I have 2 MK2.5S, both are afflicted with this. When I refer to the left side of the printer I am talking about the side that has the main board and X carriage motor.

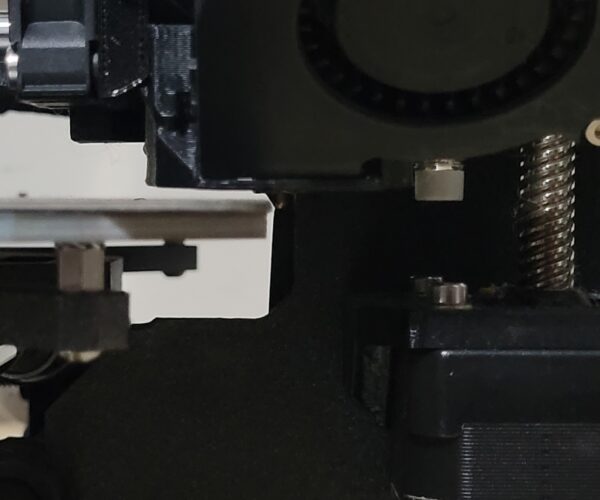

The X axis end stop is triggered when the nozzle is still ~5mm from the left edge on the smooth print bed and will move ~5mm too far to the right when physically moved. Physically pushing the X carriage all the way left results in the same issue as there is physically not enough space. When trying to print something that covers the bed it cuts off ~5mm from the left side of the print

I have tried replacing entire X carriage and extruder assemblies and the issue persists.

if I remove the block that triggers the X axis endstop from the X carriage I can, with some resistance, move the printhead far enough left to reach X=0 but the end stop will not trigger. It seems removing ~5mm from the endstop block would resolve the issue, I am hesitant to do this because of the amount of resistance I feel when pushing the X carriage all the way left.

RE: X axis end stop triggered too early

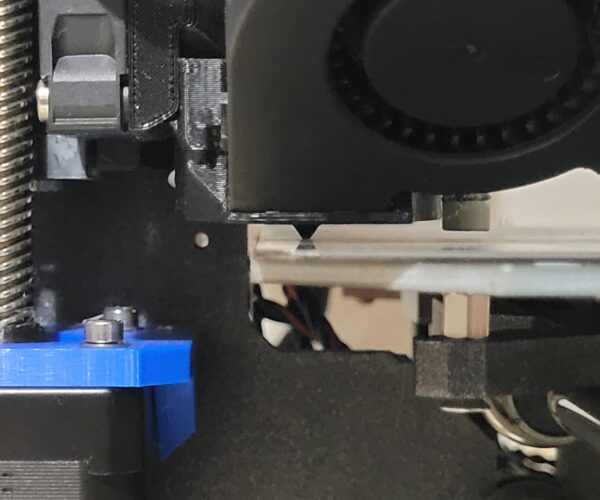

Are these genuine Prusa's? I see blue parts there, so far as I know Prusa only uses orange and black.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: X axis end stop triggered too early

I reprinted the blue part, I used the MK2S Z-axis bottom.STL that I downloaded from Prusa found here.

The Z Axis bottom is the same on the MK2S and MK2.5S. The Z-Axiz bottom was not a part that was replaced when upgrading from MK2S to MK2.5S. Everything is tight, the Z axis bottom was, as far as I could see, the exact same dimensions as the one I took off.

RE:

The only thing I can think of is the x-stop block is installed wrong, take a look at steps 64 and 65 in the print head assembly.

https://help.prusa3d.com/en/guide/3-e-axis-assembly_48816#51616

Regards

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: X axis end stop triggered too early

The end stop block is installed correctly. I made a video better explaining and demonstrating the issue.

RE: X axis end stop triggered too early

try re printing the X end stop 4mm shorter.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: X axis end stop triggered too early

try re printing the X end stop 4mm shorter.

regards Joan

This is the quick fix I have been trying to avoid, I am concerned this may result in more printing issues as the machines do the XYZ calibration successfully and I do not know how all the end stop will impact the calibrations, I guess this will be a lot faster to test than a complete rebuild so my next post will have updates about this.

RE: X axis end stop triggered too early

I look forward to your findings.

I never did the full 2.5 upgrade...

My Mk2, has the mk52 12 volt heatbed, (So that I can still use MMU1)... and

Frankenprusa, has a mk2 frame with 24 volt PSU, Einsy, 24volt Mk52 heatbed... Mk3 Y axis Platform, modified Z end pieces etc. so it's more of a Mk2.8, than a mk2.5... 🙂

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: X axis end stop triggered too early

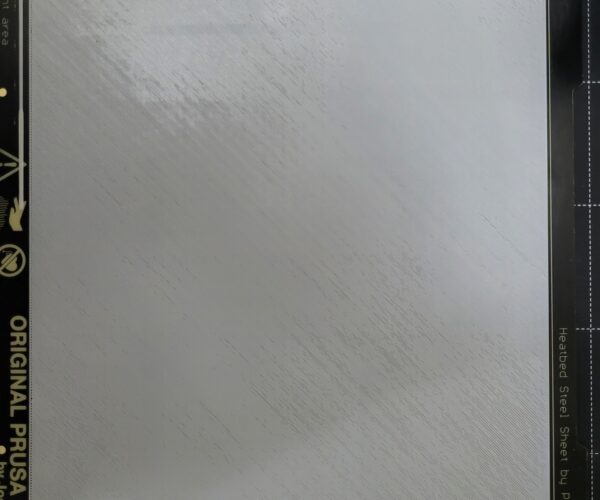

Alright, so I reprinted the end block 4mm Shorter. XYZ Calibration seems to be unaffected and I have run a full bed test on the black unit.

The diagonal over printed line is no longer present on the full bed print and I am now printing 249mm X 209 mm. Still not at the 250 x 210 mm but a marked improvement.

I will be putting the orange unit together after I get some sleep.

Next plan is to check the X and y End stops to see if I can get that 1mm missing in both directions.

I am still wondering what caused the huge deviation and would really like to figure out if it was something I assembled incorrectly. My biggest concern is that by implementing a "quick fix" that doesn't address an incorrect build I have created a possible new type of stress on the machine that could lead to new failures down the road. Maybe I am over thinking.

RE: X axis end stop triggered too early

I have reassembled my second machine aaaaaaaaand the end block with the 4mm reduction, the exact same piece that mostly resolved the issue on the black printer is too small to trigger the X axis end stop on the orange printer.

I am at a total loss, I don't understand WTF is going on. I am reprinting the End stop block with a 3mm cut instead but this seems like such a janky way to do this. Something has to be wrong either with the files I downloaded, the printed parts I made or the assembly. I just can't figure it out. Short of completely disassembling the X carriage again I am stuck.

Note: I have been printing replacement parts on my MK3 and everything I print matches the dimensions of the model.

RE: X axis end stop triggered too early

See the latest posts about MK2.5 available print bed reduction. The problem ist not the stop block, but the wire assembly and the extruder assembly parts. The cables in the back clash with the frame if you use a shorter or no endblock. While this might give you back 3 mm or so, it will make your printer more unreliably. Only solution is to change the printable parts or correct the calibration points in the firmware.