Dialing-in ASA

Some Background:

We recently made the decision to start 3D printing simple production parts for a new product we're developing. The presence of high temperatures (up to 80C) and UV exposure led us to choose ASA as the best material for our specific use. We bought a spool of Prusament ASA and had decent luck using default settings in Prusa slicer. One issue we did observe though is when we load the bed with parts, the parts at the corners of the bed warp away from the bed and fail catastrophically. I suspect this is due to slightly lower bed temps around the edges. I plan to experiment a bit to get this figured out, and that is why I came here.

My Question:

Is there a scientific approach to dialing-in a material? Where do I start? Should I try to decrease warp by adjusting nozzle temperature? Up? Down? Or, should I first try increasing adhesion by raising or lowering the bed temperature? I know I can just keep trying random things, but I need to get a grip on exactly what method will yield the best process. Anybody have a methodical approach to dialing in new materials?

RE: Dialing-in ASA

My experience is that warp problems is kind of a builtin problem when printing in ABS and ASA because it shrinks so much when cooling. Before PETG I printed a lot in ABS and parts with side length greater than 80-100mm often had warp problems. Changing printing parameters did not solve the problem.

To print with ABS (ASA) one needs an enclosure to prevent draft and keep the air temperature up around the parts. Maybe a Draft Shield will be enough to prevent warping - this is a new option in PrusaSlicer 2.2.0.

Small or thin parts and parts with short continuous side lengths is fairly easy to print in ABS and ASA.

Have a look at my models on Printables.com 😉

RE: Dialing-in ASA no answer...but my experience.

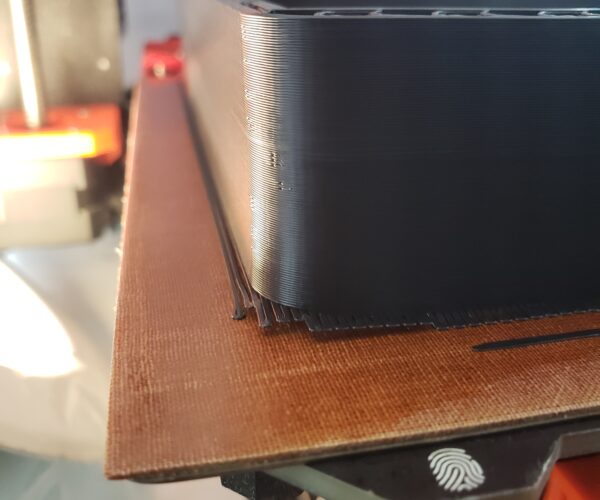

ASA warping at corners either lifting from Phenolic LE Sheet and/or pulling sheet off of magnetic base. Happens about a third of the way through a 7 hr. print.

Filament- Polylite ASA

Printing around 100 mm/sec to shorten time, but print comes out well, just warping. I've tried slower speeds with no results.

260-110c

magigoo on sheet at print areas.

Enclosure- Temp= 38c 24% humidity.

Lifts at corners only, can't rotate part on bed as it takes up the whole area.

Any ideas? I have a lot of these to print.