MK2.5S unable to find 3rd calibration point - could it be wonky Z axis?

Hi,

I just upgraded a MK2s (assembled) to MK2.5s and also replaced several parts due to grinding noise and scored axes:

- All LM8UU bearings

- Y-axis smooth rods

- X-axis smooth rods (one rod is somewhat tight but prints ok)

- Lubricated all bearings with super-lube

- Lubricated all rods with singer machine oil

I have been consistently getting errors about being unable to find the 3rd calibration point. I did manage one successful calibration (I think I got lucky) and printer said "all axis perpendicular"

Print quality was not great and a print a few CM high detached the print bed and resulted in spaghetti. To fix this I tried:

- Replace nozzle (old one had been blocked with woodfil and drilled out)

- Upgrade firmware to 3.9.1

- Factory reset

I'm now unable to calibrate XYZ after trying about 5 times. It always fails to find the 3rd calibration point.

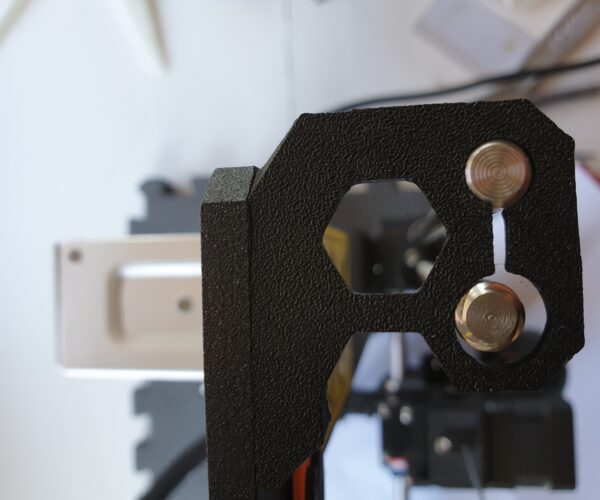

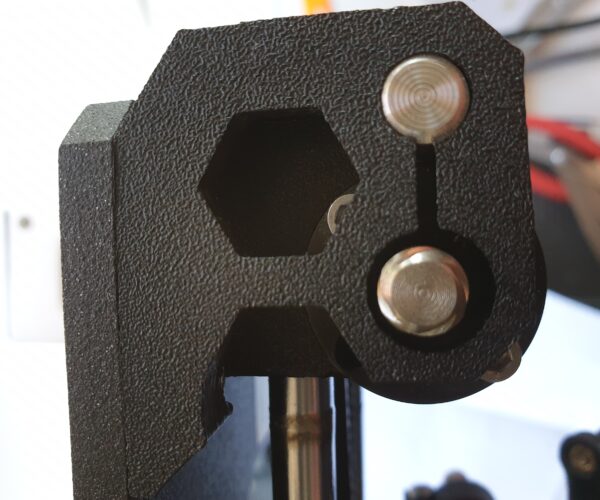

Could this be caused by Z-axis hitting the top supports? I took some photos, when the X-axis is at the bottom of the printer, both threaded rods are touching the top supports:

Left

Right

With the X-axis at the top the threaded rods are almost centered:

Left

Right

So my question: is this skew what's likely to be causing the 3rd calibration point not to be found, and if so, how to fix it? I've been trusting my frame is correctly aligned so far since it came from the factory and I also got the "all axes perpendicular" message at least once too. Anything else to check?

RE: MK2.5S unable to find 3rd calibration point - could it be wonky Z axis?

What you see in your pictures is that the rods for the bearings on z-axis are tight sitting in the parts on top of the printer, but the threaded spindle is loose there - that is how it should be. If rod and threaded spindle would be sitting thight in the top part it would be mechanically overdetermined.

Now to your problem - you don´t find the third calibration point - so you mean front position of heatbed on right side when doing a 3x3 mesh leveling? Anyway - have you had a look on minda / pinda sensor signal, when moving the x-axis? Is the sensor value changing during moving x-axis? I once had a broken cable which had this effect.

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: MK2.5S unable to find 3rd calibration point - could it be wonky Z axis?

@clemens-m

Thanks for the reply, I think you saved me from spending a long time fixing a non-problem. The failure was in the first part of XYZ calibration without the spring steel plate - calibration point at back right of the printer. I was able to position the pinda probe over the calibration point and see the light go on and off cleanly as I moved Z axis up and down over it and no flickering as X-axis moved.

I found my problem: The X axis I'd previously replaced was not installed correctly. Naively, I expected that I could just pull out the old rods and insert the new ones but this was not the case. The fix was to find the 2x screws that tension the X-axis and:

- Unscrew both screws until they are almost out

- Make sure the X-axis rods move freely within the holder

- push both ends of the X-axis together

- Tighten both screws until the X-axis is no longer loose - as soon as contact is made stop tightening

I had also previously:

- Tightened the bolts holding the Z-axis steppers to the frame mountings (visible in the bottom of the photo)

- loosened and then tightened the trapezoid nuts while the Z-axis is half way up the frame

After fixing the X-axis smooth rod tension, XYZ calibration passes first time. The adjustment made the X-axis belt very loose and it needed extruder disassembly to re-tension and trim it.

I am now able to print a very good benchy 😎