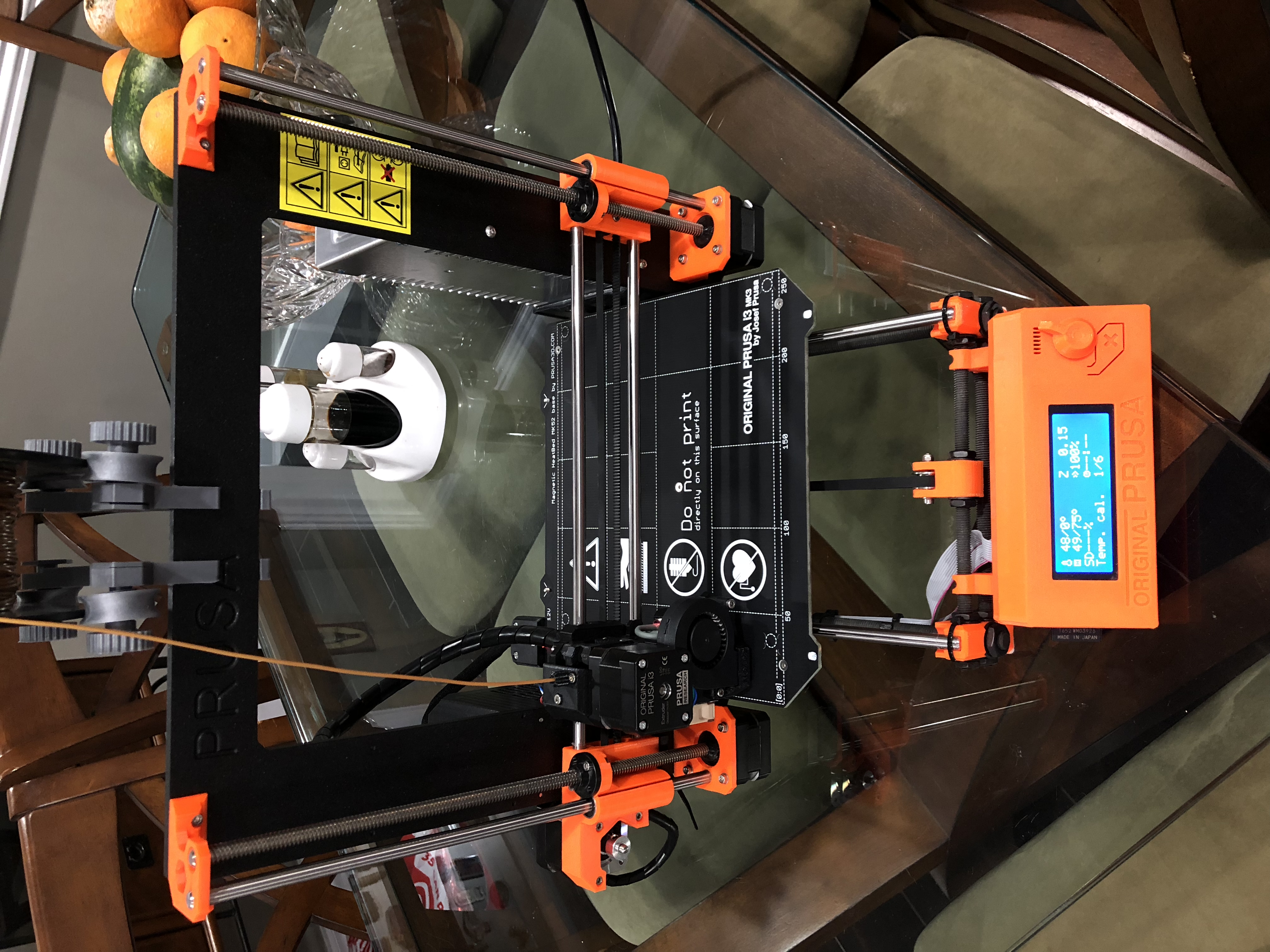

Finished my MK2.5 upgrade!

Total time for me to do the upgrade was 6 hours or so. I screwed up a few times along the way, but I made it work. EDIT: I have no idea why the image is rotated like this.

So far I've been using the same S3D profile I was using before, which I got from the MK2S forum on the last few pages. Works well as far as I can tell, but haven't done a lot of prints with it yet. It seems like it runs quieter or maybe that's my imagination? Unrelated to the upgrade, I think I'm hearing a high pitch squeaking on the bottom bearing rail. It mostly happens in the center of the rail. I ordered oil and waiting on that to come in and hopefully that will fix the problem.

When I finished and did the self testing, the x stopper wasn't triggering because the extruder part was too short to hit the switch. I used the prusa g-code since I wanted to see how the factory would run it and the parts turned out well, except that stopper part. Luckily, I remember reading someone else had that same problem and I layered mine with tape for now. It works perfectly fine, but I would like to find something solid there than rely on a piece of tape that might fall off 😆

Other minor things since moving to 2.5:

[*]You can see more little bubbles on the PEI steel sheet. Not a big deal anyways since they will go away with the bed heating over time.

[*]It seems like the filament leaves a marking more? I can scratch off the marking with my fingernail and it will go away, but it could be the filament I'm using right now? (Hatchbox PLA gold). It might have been there since the MK2S since the PCB is dark colored and the steel sheet is light colored, so you can't see anything.

[*] The temp calibration was bugging out. It always reached the last 6th point, but it would remain there for over an hour. It happened more than a few times. I think I accidentally triggered some reset, since I ran it again after that and it completed that time.

Re: Finished my MK2.5 upgrade!

squeaking in the center rail happens most often since there is less tension.... usually at the ends of the printer if the rods are slightly spread out, even by 0.5mm it will have more resistance but the center will have less... if lube don't work then time to swap for igus.

Re: Finished my MK2.5 upgrade!

I had the same problem with the x-stopper...

Here is a quick scad & stl files to make a more permanent part that I super glued to the lower back corner of my extruder body right behind the extruder fan.

translate([0,5,0]) cube([9,7,1]);

cube([9,5,7]);

translate([0,0,0]) cube([1,12,7]);