Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

Thanks for the advice!

I tried my last print with "loud" mode instead of the silent mode, and that got me further than ever before on the mk2.5, but it still failed - although way later. I was able to push the PLA again mid-print using my hands, and it started to flow again. However, the print was lost, but it makes me think that increasing the motor current might actually help. I'll try with 750mA and see what happens.

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

Wow, thanks, it works again :D. The extruder motor gets quite warm, though, so I'm not sure if I'd like to stay at 750mA. Most probably I'll try to get this down as far as possible without getting print problems, or I'll try to add some cooling.

But, wow, this really is nice. Took so long with the unreliable prints, so glad now!

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

@lena.b: Could you explain how you upped the extruder motor to 750mA? Maybe point me to a good site with explanation?

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

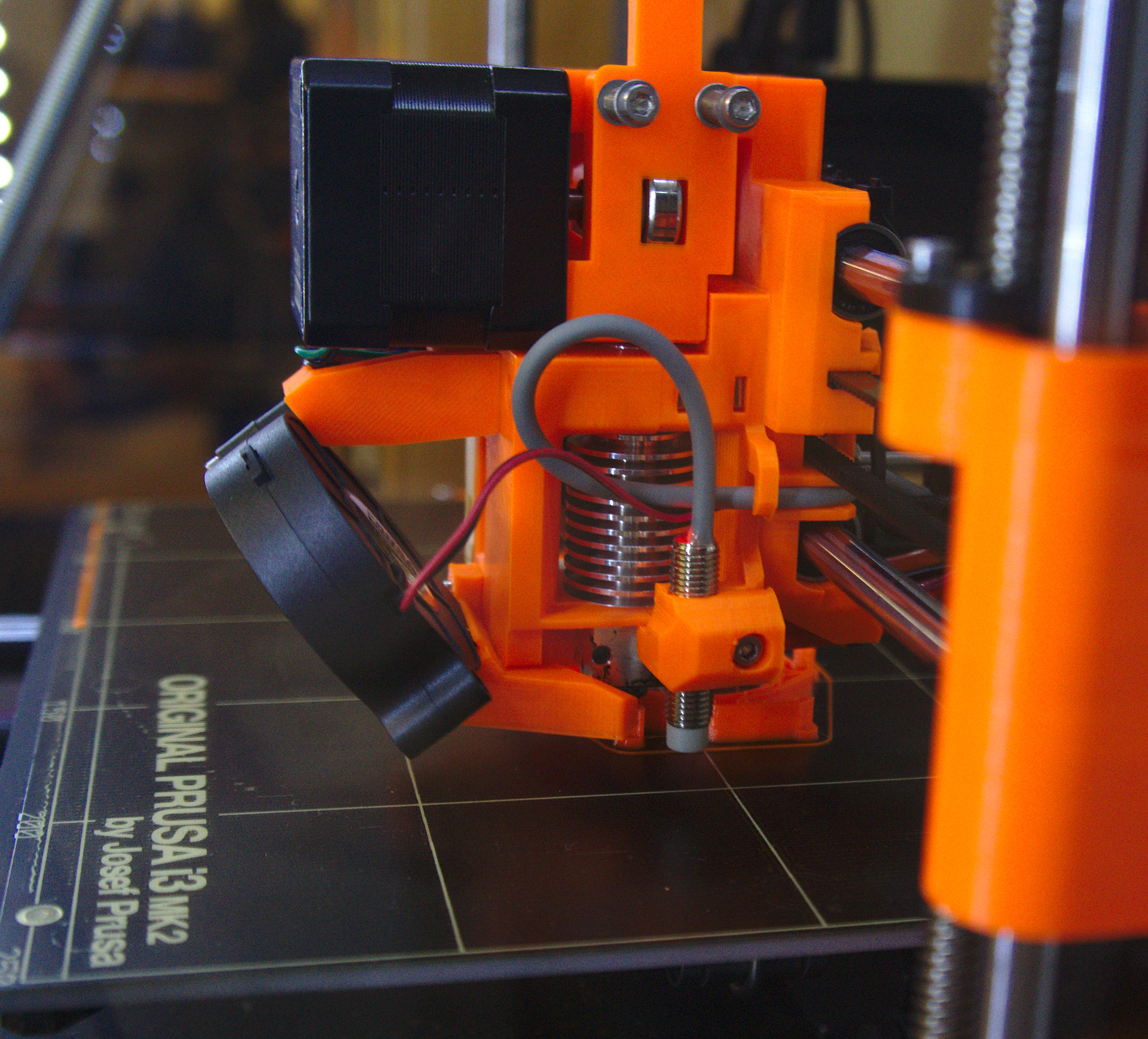

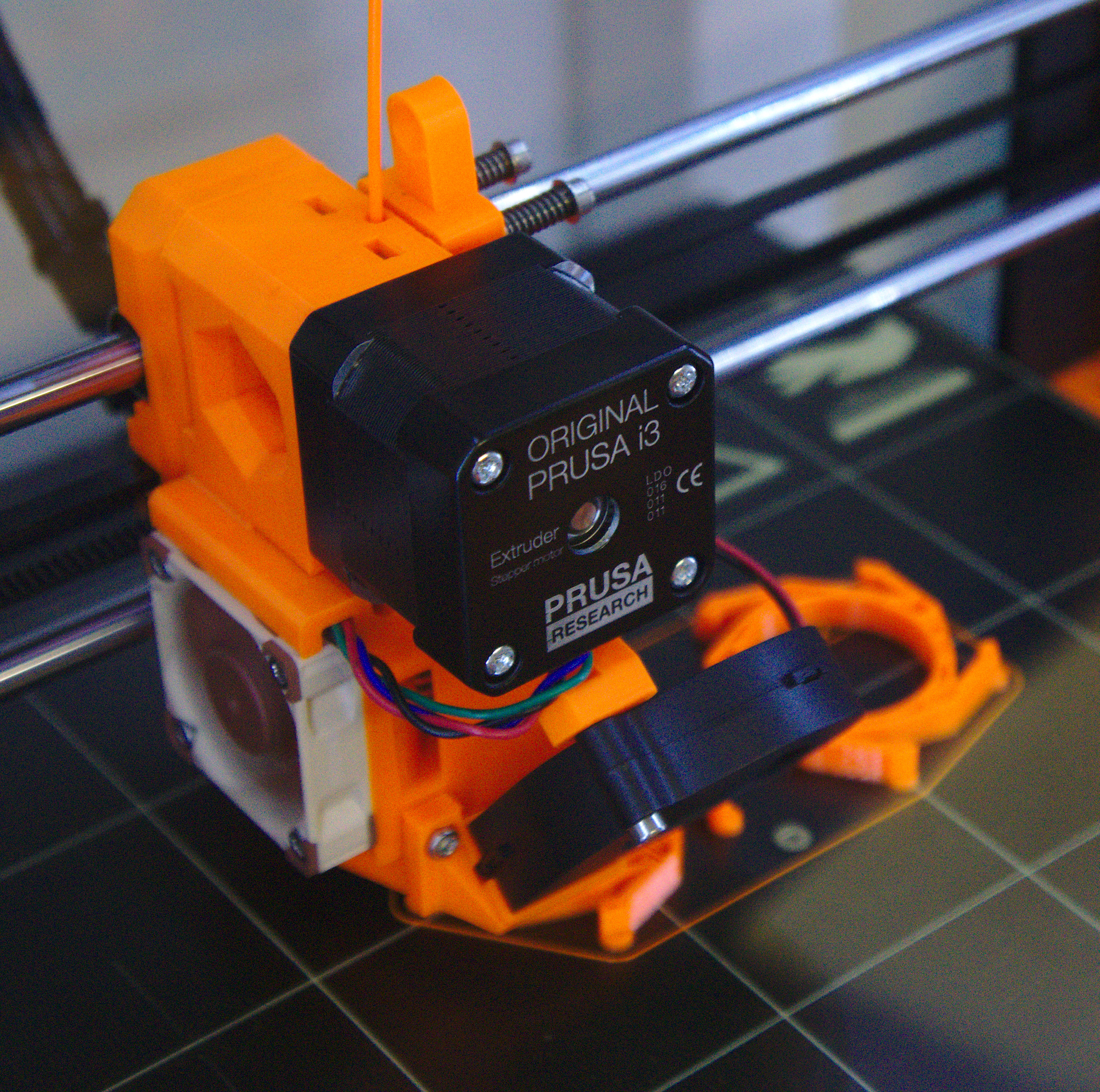

I've had issues with extrusion failures and a clogged nozzle after upgrading my Mk2 to a Mk2S with a hybrid Mk2S/Mk2.5 extruder as well. The extruder assembly now consists of a Mk2 extruder upper part and a Mk2.5 Noctua fan & PINDA V2 lower part with the R3 Dyson version (see photo 2 & 3).

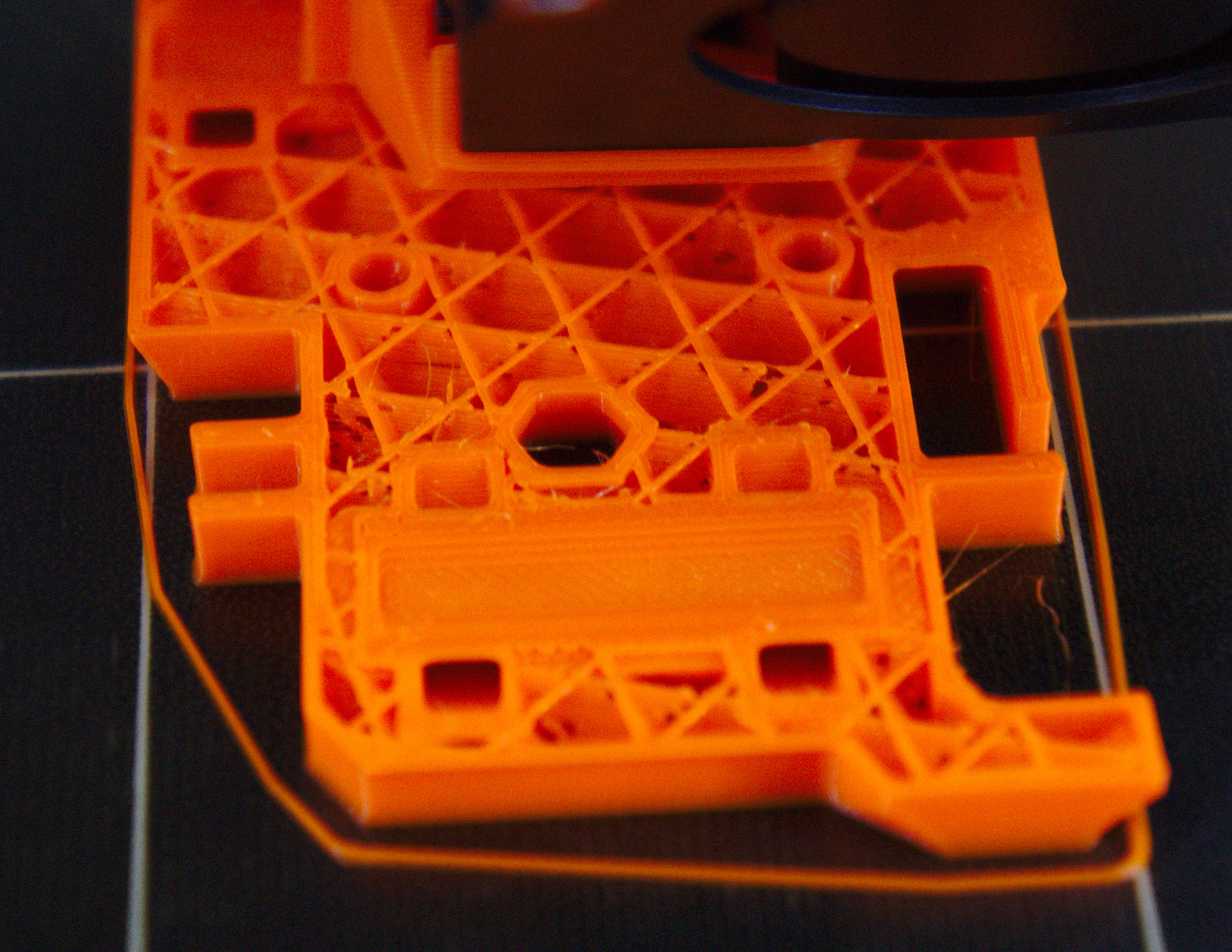

After the upgrade the prints had extrusion failures and a clogged nozzle ruining the print after a few more layers (see photo 1). Note the thin filament strands pointing upwards. It looks like the extruder wasn't able to properly retract the PETG filament.

Reading this thread I initially thought I might have a heat problem as I am operating the printer in an enclosure. The thermometer shows temperatures around 42 C after approx 30 min into a print.

I then remembered that I had removed the PTFE tube to check its state and reinserted it during the upgrade. Reviewing the reassembly instructions at https://manual.prusa3d.com/Guide/How+to+change+a+PTFE+tube+-+Original+Prusa+i3+MK3-MK2.5/761?lang=en it says in step 9 Push the black collet in. Slide the tube all the way in and hold it!

I didn't pull the collet and realized the PTFE tube might be the issue.

Using second hand pull the collet out and only then release the tube!!! THIS IS CRUCIAL for the hotend to work properly.

My problems were resolved by inserting the PTFE tube into the hotend as instructed (pull the collet). I've done two test prints since which completed perfectly - even with the enclosure closed and 42 C inside. The stranding disappeared as did the under extrusion issues.

So for the Mk2S with a Mk2.5 cooling fan and Dyson extruder body I can't confirm cooling issues with the Noctua fan.

Double check correct PTFE insertion into your hotend.

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

Wow, thanks, it works again :D. The extruder motor gets quite warm, though, so I'm not sure if I'd like to stay at 750mA. Most probably I'll try to get this down as far as possible without getting print problems, or I'll try to add some cooling.

But, wow, this really is nice. Took so long with the unreliable prints, so glad now!

Great to hear it worked. Yes the extra heat might be a problem if using enclosure. I don't have an enclosure and been running fine with 700mA, even tried up to 1000mA for a short while, but the motor was getting really hot. I did attach some heatsinks on the motor with M3 thermal tape, which do help some.

@cristoph.h5: you can use command M907 E750 to set extruder power to 750mA. Change the E-value to your liking. Other option is to download the sources, change the mA value to Configuration_prusa.h and recompile the firmware as I did. Note that getting the build environment i.e. proper Arduino IDE set up takes bit of doing, but is quite straightforward. And remeber NOT to update the libraries, that will break the build env...

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

Same problem here after upgrading to MK2.5 (R3 Dyson) and Firmware 3.4.0-RC1

Extruder starts "clicking" and less filament is extruded. After pausing->unloading-> loading-resuming the extrusion is back to normal.

I have already tried to print outside of the enclosure -> no change

I have also checked the PTFE tube as suggested -> no change

The problem arises sometimes after minutes, sometimes after hours, so i guess its not a temperature problem.

It looks like the problem starts at 70% - 90% of the print time, so i guess it could be a software issue???

any help, is Prusa support aware of the problem?

regards

Robert

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

Same issues here. I am unable to print the new spool holder after the upgrade. It has failed 2 times in the same spot. I initially thought it was the gcode and sliced it myself. I also purchased a new extruder with my upgrade and the spool holder was my first long print with PETG. 9 hour pla print is fine. Today the spool holder failed and wanted me to load filament. Basically loaded it up again and it continued. It’s about 85F in my garage. I wanted to print a new color in PET for my printer and this was one of the last prints and I believe the longest. So as others have mentioned short prints appear to be fine for me. The printer/filament is also squeaking i assume in the entrance of the new housing. Perhaps this adds to the heating up of the extruder motor.

Adding a few images. I am a 80-90s child hence my love for clear. I also noticed that by belt is rubbing so ill have to address that when i rebuild for the new clearish parts.

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

Still having problems with jams on certain models. Yesterday I printed a model sliced with KISS that uses dynamic layer heights from 0.1mm to 0.25mm (KISS changes the layer height for each layer automatically based on the slopes). The first print went fine during the day, no motor skipping or anything. However, I set my machine to print another during the night and it failed twice, on the same spot (second time I woke up to the filament change beeps). Why did the nightly print fail? I had to close to door to the room where my printer is to keep the noise down -> hotter room -> hotend cooling cannot keep up. First print was with 700mA, second 900mA for the extruder.

So to me, the reason why this happens is obvious: the new 40mm Noctua fan is not powerful enough to keep the hotend cool enough when room temperature is above normal and heat-creep causes jams when the filament flow is slow, I.e. when printing small details (lot's of retractions), low layer heights or just printing slowly. The fan is quiet alright, so quiet thhat I actually had to check the fw configuration if the fan is actually running full speed. Yes it is, it's just not very powerful fan.

I never had any problems even in a hot room when using the default E3Dv6 cooling fan and shroud. I've been thinking about ditching the Noctua fan and using the default fan, but that would require modifying the firmware because the Noctua fan's speed is monitored by the fw. This upgrade is turning out to be a mixed experience...

Crap, the lastest jam seemed to be quite ugly, I wonder how much I have to tear down the extruder to get it unclogged again... I hope I didn't break annything trying to force-feed the filament with a small screwdriver... never debug filament jams when just woke up 🙄

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

Got the clog sorted out. Turns out the 900mA for the extruder motor was enough to cause the filament to melt at the drive gears, causing a blockage right at the hotend's PTFE tube throat. And I went and jammed it int there somewhat fierce during night... 😆 . Well I got it out by removing the nozzle and pushing from the heater block side upwards. Even then it needed quite a lot of force to get it moving.

Well printer is working again and printing the model just fine since I can keep the work room's door open.

So at least for me, 900mA is too much current, motor gets hot enough to melt PLA at the gears. 750mA has been working well so I'm going to stick with that. Hotend cooling is still an open issue, not sure what to do with it...

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

Interesting that you feel its the hot end. I use octopi and my according to the temperature chart my hot end appears steady with about 80F ambient temp.

My saga continues...

Got a fresh new spool of the PolyLite PETG, went through a lot of it printing a set of parts and the failures. I tried to loosen my extruder screws a little as this once helped me print some flexible material that i had a similar problem before 2.5.

Tried a small wing part from the spitfire and it failed in 20 mins, ran it again and it completed.

I tried another spool holder and it failed much later than the first 3.

So i went the opposite direction and tightened them down in anger and told myself ill blow this $25 spool on sorting this out or blow 800 on a mk3 ha...

So i torqued that SOB down and fired off the Spitfire_fuselage_1.gcode overnight which is what have been wanting to print. Woke up to a bed of parts. So after work fired up a wingR_1.gcode and I'm half way there living on a...

Ill try that spool holder again and if that doesn't go again ill try with the PET that Prusa shipped with the upgrade.

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

The actual nozzle temp is steady for me too, but that's not the issue here. With hot end temperature I meant the hot end heatsink temperature, not the nozzle/heatblock temperature. When the hot end heatsink isn't cooled enough, the heatbreak gets too hot -> filament starts to melt too early, possibly deforms/swells and clogs the heatbreak. Optimally everything above the heater block should be as cool as possible, so filament starts to melt only after entering the heater block and nozzle.

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

Ok i understand.

Well i have good news. Spitfire printed with out issue, then the spool holder printed with out issues. 2 wing sections printed with out issue. All 5+ hour prints. At this point my confidence is much higher and can wait to print more PET. Maybe with it loose the gears were grinding down the filament during sections with a lot of retracts? I have no idea and have no other conclusions or data points to present except to tighten the extruder gear.

I don't think its the filament or the printer just the moron who put it together.

"Place both screws into the Extruder body and tighten them. The screw's head should be almost aligned with the printed surface."

The picture looks like the screw heads are slightly above the printed surface. Perhaps i didn't perform this step correctly or my parts are a little smaller. I don't know.

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

Phew. I'm back again. Apparently it's still happening. Just later. And, I started to compare my older MK2S prints with the newer MK2.5 ones, and it seems that they are way worse quality-wise. I thought it might be the filament (wet or something), but using a new spool has the same issues.

I'll try having a look at the PTFE tube thing, I am unsure what I did there, too long ago. So, again, taking the extruder apart. Currently, I wish I did not change the printer in the first place. It seriously enerves me and takes a serious amount of time, which I do not really have currently :-/.

@cristoph.h5: as pekka.p mentioned, you can use command M907 E750 to get it to 750mA. I used the octoprint "gcode scripts" in the settings to inject it.

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

I have same problem. I thing this is problem with printer fan cover. Air flows direct to nozzle and fillament inside nozzle is chilled. Thermal senzor is in heat-block so printer dont recorded problem. I try edit original fan cover, air flow is now directed just below nozzle, and this worked for me. Yes now is overgans a bit worse but printer is now reliable. I dont heard any special sounds from extruder motor (skips) and I did not notice any pause in printing (befor many).

You can try this: https://drive.google.com/file/d/1UvCM_Yq-KXU0NijeDIw3FfXsn9lcowsQ/view?usp=sharing

Maybe help you 🙂 and sorry for my english 😀

edit: I use Cura and Overhangs is bad, but when i use Slic3r that printed part is almost identical with this from original fan cover 🙂 (in Slic3r is temperature higher by 5°C)

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

Been having problems with jamming still, my print success rate is currently ~70% due to jamming on some more demanding models.

So far, best success is with these steps:

- increase stepper power to 950mA. 750mA is ok for most prints, but some require bit extra

- open room window. Chills the room temp a bit -> cooler hotend top section, less jamming

- added a silicone sock the hotend. Didn't do much regards the jamming, but temperatures are bit more stable so no harm done. Also keeps the heater block and nozzle cleaner.

- slice without z-hop. Bit faster prints and faster overall throughput of the filament -> less time for the filament to heat in the heatbreak and jam

- curse MK2.5 to hell. Doesn't help with jaming even a bit, but helps with nerves

- lastly, one thing that I've noticed that helps with multiple printers: do a cold pull before starting a print. All my printers currently have all-metal hotends and they all have jamming problems with some PLA filaments. Prusa MK2 was the most perfect of the 4 printers I have, since it's the only non-bowden setup. I've tested the difference of doing multiple prints with and without cold pull in between the prints on 2 printers now, MK2.5 and other printer that has a Prometheus v2 hot-end. With both, the cold pull between prints helps; on MK2.5 it means that challenging prints most likely won't fail with the extruder clicking and on the other printer it means that the print quality stays good when filament flow isn't hindered by partial jams and bowden's spring effect.

At first I thought it was a fluke, but after multiple tries I saw that the cold pull effect is really repeatable. Not sure why, maybe there's dirt or some filament crap that sticks to the heatbreak during prints and starts to hinder the filament flow. And cold pull removes that crap.

Edit: one more trick, but this needs to have someone babysitting the printer while it's printing. I've managed to salvage few prints when the extruder clicking starts by pausing the print, retracting 10mm, refeeding 10mm and resuming the print. This seems to allow the printer to continue at least some time before next click session. I use Octoprint and this probably cannot be done without it.

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

Hi guys,

Does anybody resolve this issue?

I have this problem with MK3. At first, the printer worked flawlessly. But right now, I have a filament jam in 90-95% of prints.

I also switched to R3 extruder ( one of the successful prints).

I know, that the issue is not in the gcodes as I have tried several slicers or the original Prusa gcodes on the card for MK3.

No success. New PTFE tubes installed (as suggested on the support) but nothing is helping.

I did not have any issues like that with my MK2S with over 250days of pure printing time. And that was my start of 3D printing. Every issue I have had at that point was my own error, but I do not think, that this is the issue now.

Thanks guys.

Filip

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

Hi guys,

I'm as well at the point where printing with PLA is nearly impossible since upgrading to 2.5.

Here are the thing I already tried without success:

My last resort is now disassembling the hotend and give it a through cleaning as much as I can. If this fails as well I'm lost.

I appreciate any further ideas which may help us to get this solved.

Regards

Manu

Design, Print, Repeat

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

Hi guys,

I'm as well at the point where printing with PLA is nearly impossible since upgrading to 2.5.

Here are the thing I already tried without success:

My last resort is now disassembling the hotend and give it a through cleaning as much as I can. If this fails as well I'm lost.

I appreciate any further ideas which may help us to get this solved.

Regards

Manu

So it seems I have found my source of frustration and failed prints: a not properly assembled hot end. During disassembly I registered that the heater block was quite easy to turn on the heat break. So somehow the heater block came loose. After disassembling everything, cleaning it as good as I could and reassembling it, making sure everything sits tight I seem to be back in business. I don't know how it came loose but maybe during the upgrade something wiggled around a bit and lead to this.

Design, Print, Repeat

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

Hi,

After upgrading to the MK2.5 recently I also ran into problems with a clogged nozzle. In my case the issue arises when unloading filament, it just cut's of filament at the top of the cooling rib, leaving a big part in the cooling. The only way to clean this is a full disassembly of the extruder, other attempts like heating up and try to push it through weren't very successful.

Any thoughts on this problem? I use the latest (updated) extruder parts.

Kind regards,

Alex

Re: Extrusion failure / clogged nozzle since Upgrade to MK2.5

@alex.v3 I've had that happen to me once, the unloading left a trip of filament into the hotend that caused a jam when trying to feed new filament. Not sure what to do to make sure that doesn't happen. I usually do cold pull and not use the unload option.

Still having problems with jamming with prints that have lot's of retractions. Prints that don't have lot's of small details are fine. Haven't had time to disassemble the extruder and check the PTFE tube. I suspect that it's not the culprit, but I'm going to check it anyways and also properly bevel the tube end so there's now gap between it and the heatbreak.

Still, as I needed to print something that suffers from jamming, I hacked something together on the slicer that seems to help. I noticed that when the extruder is jamming, pausing the print from Octoprint, retracting 10mm, waiting few seconds, feeding 10mm and the resuming the print clears the jam and the print continues ok for some time. So I added following g-code to be executed during each layer change:

G91 ; relative coordinates

G1 E-10 F300 ; retract 10mm slowly

G1 Z1 F2000 ; optional z lift

G4 P1000 ; sleep 1 second

G1 Z-1 F2000 ; optional z lower

G1 E10 ; prime 10mm

G90 ; absolute coordinates

M83 ; relative extruder coordinates

So far the ~42h print has been progressing without gaps for 8+ hours. I had to hack this together mid print because I already have few partly missing layers that need to be fixed, if the print finishes.

This does add some extra time to the print, but for now it seems to help getting the print done. Also there seems to be a small blob after the layer change, for some reason the 10mm feed produces some extra? Maybe some jam related extra pressure or something...