Printing pc and abs

Will it be possible to print ABS and PC with the XL?

As far as I know you need an encosure when printing these materials … and the XL seems rather huge to build an enclosure around.

also, that would make the XL a printer that is too big to be situated in a living area in the house.

am i wrong?

RE: Printing pc and abs

Mmm,

first: it is actually known that that screen is NOT included

…. Also that that screen is not available (yet)

source: https://www.prusa3d.com/product/original-prusa-xl-6/

“*Draft shield is not included”

Second: imho, that screen is not goong to make a big difference.

the XL is corexy-printer. The bed starts at the top and is lowered with every layer.

printing with nylon or pc, abs, … needs a steady, draftfree and warm environment to prevent a big difference of temperature between printed layers and freshly-printed layers.

such a difference makes the colder layers to shrink, react in a different degree as the freshly printed layers, causing the printed object to warp, … in the worst scenario, thus making the object bend and breaking loose, spaghetti … or less bad: a bend, warped object.

the screen will protect the bottem of the printer of any drafty air, making temp more steady. So far so good, … but this printer does NOT print on the bottom. It prints at the top, where, even with a screen, there willot be protection against drafty air, nor keeping the temperature high around the object.

As we all know, heat rises. That screen is not capable to capture the heat.

.

RE: Printing pc and abs

On the same page, under printer dimensions, you come across the following,

top enclosure cover (separate future add-on).

In that case, the XL becomes an enclosed printer.

RE: Printing pc and abs

On the same page, under printer dimensions, you come across the following,

top enclosure cover (separate future add-on).

In that case, the XL becomes an enclosed printer.

Great pont, Rene.

I totally missed that! Thx

RE: Printing pc and abs

I'm also interested in an enclosure solution for the XL. If they haven't released one by the time I receive my XL, I may design my own. But I ordered a partial-assembled 5-head version in week-2, so I might be waiting another year. 😉

Whatever you find to do with your hands, do with all your might!

RE: Printing pc and abs

Designing your own could be a really fun and rewarding project, especially if it ends up being exactly what you need. I'm curious, have you done any preliminary research on enclosure solutions for the XL? There are a lot of different options out there, ranging from simple DIY enclosures to more complex, pre-built structures. Also, what do you plan on using your XL for? I imagine that could play a big role in determining what type of enclosure you ultimately decide to build or purchase.

RE: Printing pc and abs

I'm not as concerned about Prusa offering an enclosure (I'll probably build my own) as much as I am about knowing the temperature limitations of the XL

I've been working on printing larger ABS and PA prints and learned the hard way that the printed extruder parts on the MK3S+ do not do well above 50 degrees C enclosure temperatures. I've had the idler door warp causing under extrusion, as well as the PINDA holder which made mesh leveling almost impossible. I ended up printing all new extruder parts in nylon (though, I probably should have used PC).

I'm still going through some trial and error trying to raise the enclosure temperature to get larger ABS and PA prints not to warp... but what I've learned so far is the MK3S+ really isn't built for enclosure temps over 50C (and should probably be kept under mid 40's). With the nylon extruder parts I've done a few successful larger ABS prints with approx 55C enclosure temps, but I think I need to go higher to get good results with nylon (at least PA12).

Are the any specs on the operating temperature limits of the XL?

RE: Printing pc and abs

I do not have the XL, but prior to getting the enclosure for the MK3S I did print quite a bit of ABS (and some PC Blend) with good results with no enclosure.

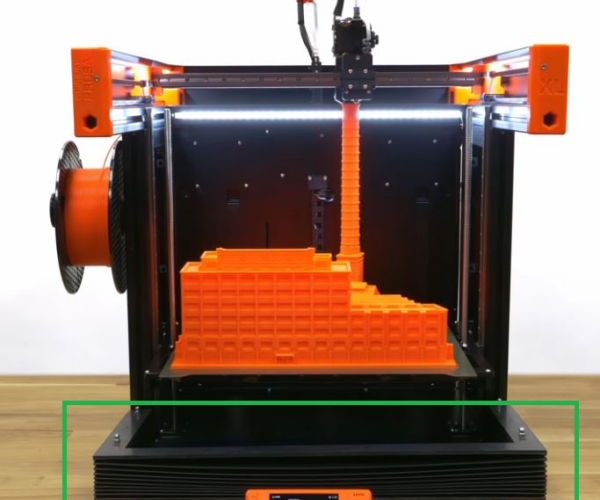

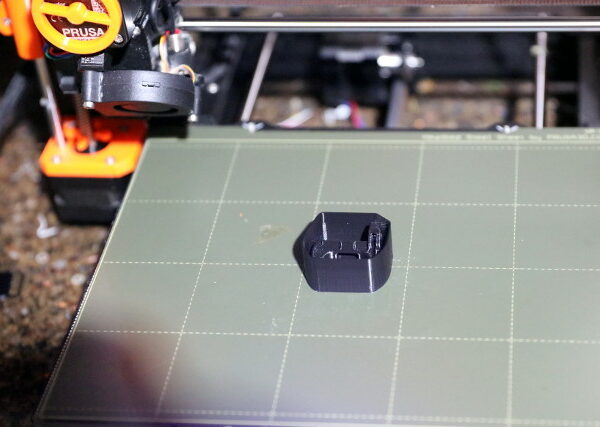

I do think that the enclosure adds to the overall quality of the prints (using any filament type) and the draft shield option (both PS and Cura) can help out if you do not have an enclosure. The photo below shows a draft shield around a remixed fan shroud.

A few best practices I've learned over the years to help with the overall quality of ABS (and PC Blend) prints are.

1. Pre-heat the machine to ABS temperature and let it sit and stabilize, maybe 15 minutes or so before launching the print.

2. Use something like Layerneer both as an adhesion booster and release agent. I learned the hard way on my first PEI build plate.

3. When the print finishes, let it cool to almost room temperature before attempting to remove it from the build plate.

4. (Particularly with PC Blend, not so much with ABS.) Do not leave a higher-temp filament in the machine overnight. Learned the hard way on this as well.

RE: Printing pc and abs

Thanks for the tips jsw!

Yeah, if it's a small part, even having an "un-heated" enclosure and enabling the draft shield gives me pretty good results. Larger and taller parts I've had to heat the enclosure otherwise the warping ruins the part.

I am starting another thread in the MK3 section on printing with high enclosure temps (the post/topic is still pending mod review).

Regarding the XL - considering it's a larger printer, I'm assuming (hoping?) the Prusa engineers took into account being able to operate within an enclosure with elevated temperatures.

Anyone know the best way to ask technical questions to the Prusa team (like operating temperature limits)?

RE: Printing pc and abs

In the printable page for the xl parts they call out PC for some parts and petg for the rest. But I am not sure what temp that would make it okay to print to. It also didn't seem like they were using PC for the extruder which seemed strange to me. https://www.printables.com/model/449554-xl-printable-parts

RE:

Yes, I printed already some PC-Blend from Prusa and it worked quite well. I build a very basic Enclosure, which can be removed in a few seconds from Polycarbonate sheets. (It is ugly AF, because we really just went for it)

For example I printed a 2 Centimeter big print in place Ball Bearing, which is fully functional with 0.6mm Steel nozzle.

I use the Enclosure also for large PETG prints. It gets to 37c° when you use jalf the bed at 85c° (38c° Room temperature) and it goes to 44c° when using the whole bed at 105c° (my PC Blend Settings).

There is also someone here in the Forum who built this super amazing enclosure with a lots of cool Ideas and really engineered with a filter system and so on. Check out that thread if you like. I am happy with mine though - it was a chaotic and fun Project where I learned a lot.