Questions about printing custom models with IS

Hi all,

I have a custom 3d model I print often on my MK3S+ and MK4 and was super impressed with the almost 2x speed increase with the new IS profiles. I just updated my MK4 to 5.0.0-alpha1 to test out the input shaper functionality and I'm running into issues, specifically with sharp corners, more details below:

Printer: MK4

Firmware: 5.0.0-alpha1

Prusaslicer version: 2.6.0-beta3

Profile: 0.20mm Input Shaper

Filament profile: Generic PLA built in profile that came with yesterday's config updates (230 C first layer, 220 C for the rest, bed at 60 C)

Filament: Polymaker PolyTerra Marble White (something I print with all the time, going through multiple rolls per month)

Other settings changed in Prusaslicer prior to slicing:

- Changed default infill to rectilinear, stayed at 15%

- Enabled a brim on the second, larger model mentioned below

- All other settings left default

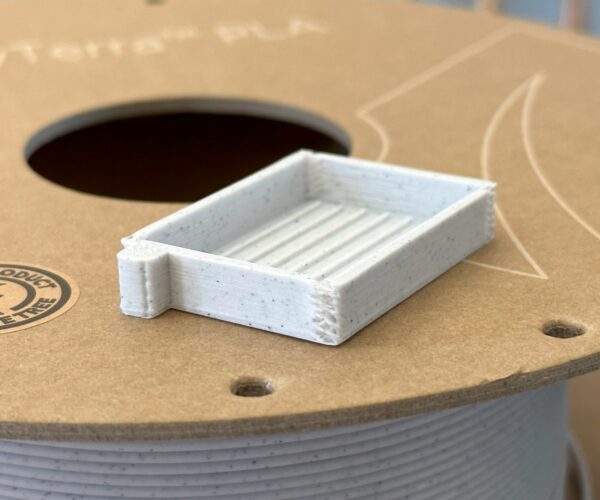

The smaller model is a tray with a handle that is 32.8 x 49.2 x 8mm. It's basically just a rectangle box with a hole cut out to make walls, normally these print with sharp corners on my MK3S+ and MK4 with previous firmware, but now, all 4 corners have huge gaps all the way up them, you can see straight through the corners and they are super weak. I was able to pull on the wall slightly and it just broke off.

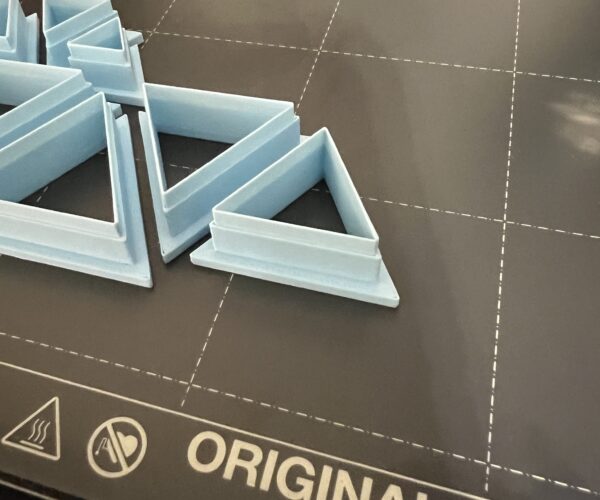

Same thing happened with this slightly larger print (40 x 80.15 x 49.2 mm). I stopped the print partway through to avoid wasting filament since it started to do the same thing. I also noticed on the infill layers, it was going so fast that it wasn't making a clean infill grid like I'm used to, it was leaving a ton of gaps in the grid, which I believe attributed to minor layer shift as the sides weren't as smooth as I'm used to.

My main questions regarding this:

- Is there something I did wrong?

- Are there settings I should have changed in Prusaslicer with the new IS profiles to have better sharp corners?

- Does anyone know why this is happening?

- In general, does input shaping handle corners well, or should it only be used for rounder objects?

I'm happy to test any settings and help contribute to fixing this if it's related to issues with the alpha firmware. Thanks in advance!

RE:

This looks like the flow characteristics for PolyTerra are different enough from something like Prusament that you might be hitting flow rate limits and under extruding. That or the Pressure Advance algorithm (also new in 5.0.0) thinks the pressure is higher than it is when it enters the “coast” phase approaching a corner. Hard to say. But this seems like the sort of thing Prusa wants (or at least should get) feedback on.

In the meantime, if you are willing to do some tuning you might be able to improve the output. The goal would be tofind the max flow rate for PolyTerra through the nozzle and create a separate PLA profile for that, and also calibrate Pressure Advance for PolyTerra once you know the max flow rate if needed.

This is the sort of thing folks encounter when pushing the limits of a hotend/filament combination.

RE: Questions about printing custom models with IS

Makes sense. I figured Prusa might be interested in this sort of feedback, which is part of why I posted it. Thank you for the video as well!

PolyTerra tends to require a higher temperature than other regular PLA I use, so that may be part of it too.

RE: Questions about printing custom models with IS

My first guess would be pressure advance which is somehow related to maximum flow rate.

In general I am a little curious if the Mk4 max flow rate is in general to low for these fast profiles.

Keep us updated if you can find better profile settings.

(My Mk4 is about to arrive in a week)

RE: Questions about printing custom models with IS

Hi all,

I have a custom 3d model I print often on my MK3S+ and MK4 and was super impressed with the almost 2x speed increase with the new IS profiles. I just updated my MK4 to 5.0.0-alpha1 to test out the input shaper functionality and I'm running into issues, specifically with sharp corners, more details below:

Printer: MK4

Firmware: 5.0.0-alpha1

Prusaslicer version: 2.6.0-beta3

Profile: 0.20mm Input Shaper

Filament profile: Generic PLA built in profile that came with yesterday's config updates (230 C first layer, 220 C for the rest, bed at 60 C)

Filament: Polymaker PolyTerra Marble White (something I print with all the time, going through multiple rolls per month)Other settings changed in Prusaslicer prior to slicing:

- Changed default infill to rectilinear, stayed at 15%

- Enabled a brim on the second, larger model mentioned below

- All other settings left defaultThe smaller model is a tray with a handle that is 32.8 x 49.2 x 8mm. It's basically just a rectangle box with a hole cut out to make walls, normally these print with sharp corners on my MK3S+ and MK4 with previous firmware, but now, all 4 corners have huge gaps all the way up them, you can see straight through the corners and they are super weak. I was able to pull on the wall slightly and it just broke off.

Same thing happened with this slightly larger print (40 x 80.15 x 49.2 mm). I stopped the print partway through to avoid wasting filament since it started to do the same thing. I also noticed on the infill layers, it was going so fast that it wasn't making a clean infill grid like I'm used to, it was leaving a ton of gaps in the grid, which I believe attributed to minor layer shift as the sides weren't as smooth as I'm used to custom printing.

My main questions regarding this:

- Is there something I did wrong?

- Are there settings I should have changed in Prusaslicer with the new IS profiles to have better sharp corners?

- Does anyone know why this is happening?

- In general, does input shaping handle corners well, or should it only be used for rounder objects?

I'm happy to test any settings and help contribute to fixing this if it's related to issues with the alpha firmware. Thanks in advance!

RE: Questions about printing custom models with IS

Hi, I have the same issue too. I'm using Polymaker Terra fossil grey for this print, and similar defects at corners appear. These defects appear at obtuse angles too, so it seems like it's not solely a sharp corner issue. I am using lower temperatures though- my filament prints nicely at 205C.

Details:

Printer: MK4

Firmware: 5.0.0-alpha1

Prusaslicer version: 2.6.0-beta2

Profile: 0.20mm Input Shaper

Filament profile: 15% grid infill, 3 vertical walls, no supports/brim/skirt, 215C for first layer, 205C for others

Filament: Polymaker PolyTerra (happens on various colours, such as orange or white)

RE: Questions about printing custom models with IS

Hi,

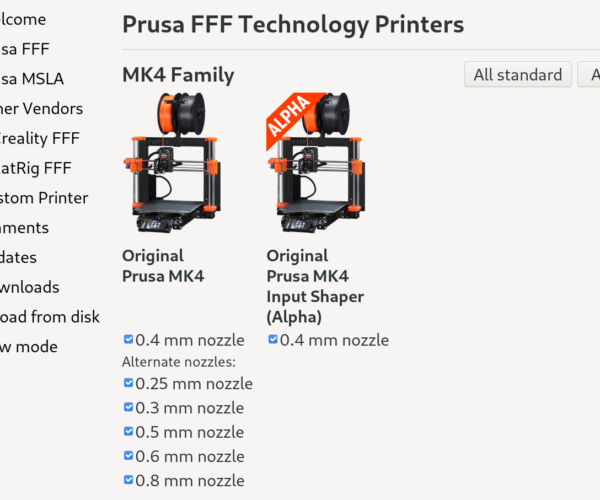

I am also running 5.0 alpha and using PS 2.6.0 beta 4. Where do you get the 0.2mm input shaper profile? I only see .20 quality and speed. My apologies - I’m still a little new.

Thanks,

David

RE: Questions about printing custom models with IS

Hi,

Thank you for the reply. I had skipped the config wizard but now have it working:). I am very interested in this thread because I am using Polymaker filament as well.

Thanks,

David

RE: Questions about printing custom models with IS

Hi Kepler,

Perhaps I responded to the wrong message. I apologize if so. I have a MK3S but received my MK4 last week. I am using 5.0.0 alpha, PrusaSlicer 2.6.0 beta 4 (updated it yesterday) and Polymaker PolyLite PLA when printing polymer clay earring cutters for my wife. I didn’t realize I needed to run the configuration wizard to get the 0.2 IS preset but now have it working. I used default Prusament PLA settings even with the higher temp and have had no issues with corners *yet*. Seams on round objects are worse and some thin interior details have been unacceptable. I wonder if something was fixed in 2.6.0 beta 4 that might help with the corners. I am also curious about the thread in general in case I run into the same.

RE: Questions about printing custom models with IS

Hi all,

I have a custom 3d model I print often on my MK3S+ and MK4 and was super impressed with the almost 2x speed increase with the new IS profiles. I just updated my MK4 to 5.0.0-alpha1 to test out the input shaper functionality and I'm running into issues, specifically with sharp corners, more details below:

Printer: MK4

Firmware: 5.0.0-alpha1

Prusaslicer version: 2.6.0-beta3

Profile: 0.20mm Input Shaper

Filament profile: Generic PLA built in profile that came with yesterday's config updates (230 C first layer, 220 C for the rest, bed at 60 C)

Filament: Polymaker PolyTerra Marble White (something I print with all the time, going through multiple rolls per month)Other settings changed in Prusaslicer prior to slicing:

- Changed default infill to rectilinear, stayed at 15%

- Enabled a brim on the second, larger model mentioned below

- All other settings left defaultThe smaller model is a tray with a handle that is 32.8 x 49.2 x 8mm. It's basically just a rectangle box with a hole cut out to make walls, normally these print with sharp corners on my MK3S+ and MK4 with previous firmware, but now, all 4 corners have huge gaps all the way up them, you can see straight through the corners and they are super weak. I was able to pull on the wall slightly and it just broke off.

Same thing happened with this slightly larger print (40 x 80.15 x 49.2 mm). I stopped the print partway through to avoid wasting filament since it started to do the same thing. I also noticed on the infill layers, it was going so fast that it wasn't making a clean infill grid like I'm used to, it was leaving a ton of gaps in the grid, which I believe attributed to minor layer shift as the sides weren't as smooth as I'm used to.

My main questions regarding this:

- Is there something I did wrong?

- Are there settings I should have changed in Prusaslicer with the new IS profiles to have better sharp corners?

- Does anyone know why this is happening?

- In general, does input shaping handle corners well, or should it only be used for rounder objects?

I'm happy to test any settings and help contribute to fixing this if it's related to issues with the alpha firmware. Thanks in advance!

I think it's less about doing something 'wrong' and more the fact that the one stock profile that's been provided with IS isn't going to be a One Size Fits All solution for all prints. I believe the expectation is to use it as a starting point to tweak from there and create your own profiles.

I had a similar (albeit less pronounced) issue with my PolyTerra and slowing down the external perimeter fixed that right up. I would say since your object is quite small, that the issue is going to be more pronounced as well. I would try slowing down both the Small Perimeter and External Perimeters and see if that fixes your problem like it did for me. 👍

RE: Questions about printing custom models with IS

Same thing I told OP, I would slow down the External Perimeter to fix this up. I had the same issue, and not only did slowing down the one setting fix it, it also improved the entire dimensional accuracy!

RE: Questions about printing custom models with IS

I know it's been a few weeks now, but I have still not gotten better. With the release of both PrusaSlicer 2.6.0 and MK4 IS-alpha2 firmware within the last few days, I'm going to update both and reslice and see if I get better results. I will also try slowing down external perimeters, though I also get skipping issues with infill, so we'll see. I'll report back!

RE: Questions about printing custom models with IS

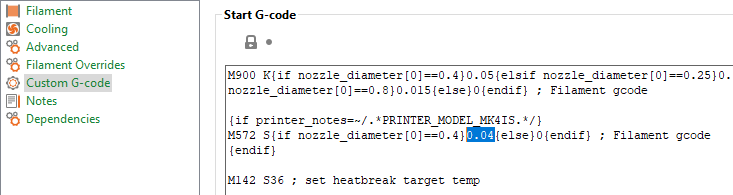

This is most likely incorrect pressure advance value for this particular filament.

RE: Questions about printing custom models with IS

Hi,

@cipis is right. I experienced something similar though less dramatic.

By the look of it you should try to reduce pressure advance. Try 0.02 or even 0.01.

Slowing down will also improve the result since the pressure advance has less work to do at lower speeds.

RE: Questions about printing custom models with IS

Where is the difference between the M900 K command and the M572 S ? When I do the K-Value tuning, which command do I need to change?