Quality issues occured

I did some prints so far with the new input shaper firmware and profile and they all worked fine, mostly self-designed stuff, like this ring:

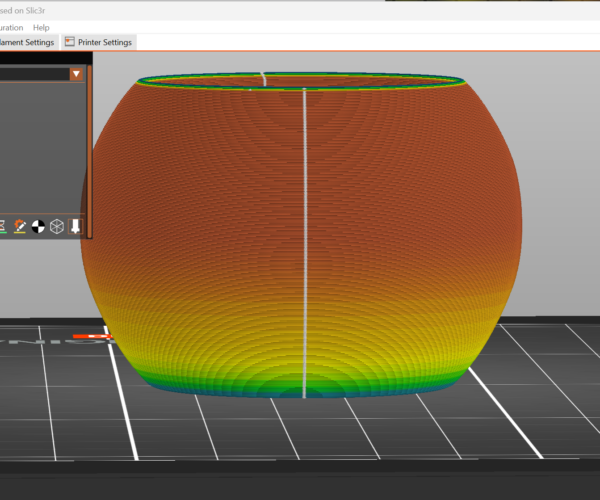

Yesterday I tried to print this:

https://www.printables.com/model/39755-spheric-tealight-holder/files

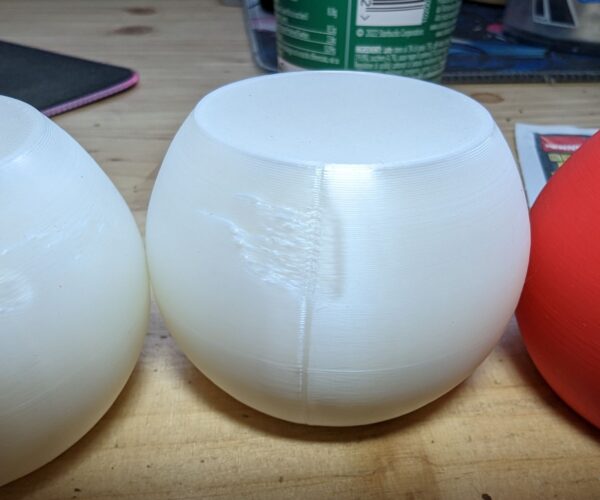

and first, I used a Genric PLA profile with Prusament White (too low temp), with this result:

switched to Prusament Profile, improved a bit:

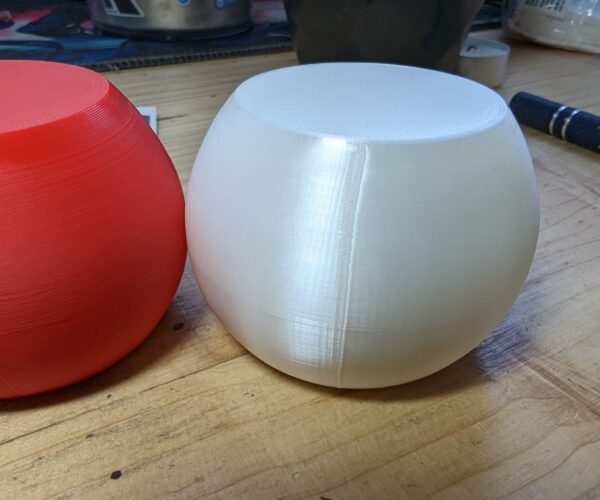

Nozzle Temp 235 (run out of white prusament, switched to red!):

And here is a 0.20 Speed without Input Shaping (same firmware):

RE: Quality issues occured

I have exactly the same problem. It only occurs with Input Shaper. If I use a normal profile without input shaping but the same firmware everything looks as it should.Have you been able to solve the problem? Other than using the normal profiles.

RE: Quality issues occured

The problems that we see here and in other threads is the logical consequence of Prusa’s absurd idea of Input shaper, using the same precalibrated profile for all the MK4 units. They ship the machines without an accelerometer, even if the buddy board has a port for it, and there’s no option in the menu for using it, if the user decided to get an accelerometer elsewhere.

It isn’t precisely a secret that correct input shaper implementation needs absolutely to be calibrated for every individual printer installed on the custom bench/enclosure where the machine is gonna work.

Prusa want us to believe that the same precalibrated setting will work fine for all the printers and no accelerometer is needed at all. Well, it seems that they’re contradicting themselves. because in one of the XL blog entries you’ll find the following statement (I’m quoting Prusa) :

“Question : Does the XL extruder have an accelerometer built in?

Answer: Yes, it does – it’s vital for correct Input Shaper configuration”.

So, accelerometers are vital for input shaper in the XL, but they are totally superfluous for the MK4 ?. Let me raise an eyebrow in disbelief (and then the other ).

RE: Quality issues occured

I’d happily just add a third party unit to the printer if it was an option - hopefully it will be at some point?…..

The problems that we see here and in other threads is the logical consequence of Prusa’s absurd idea of Input shaper, using the same precalibrated profile for all the MK4 units. They ship the machines without an accelerometer, even if the buddy board has a port for it, and there’s no option in the menu for using it, if the user decided to get an accelerometer elsewhere.

It isn’t precisely a secret that correct input shaper implementation needs absolutely to be calibrated for every individual printer installed on the custom bench/enclosure where the machine is gonna work.

Prusa want us to believe that the same precalibrated setting will work fine for all the printers and no accelerometer is needed at all. Well, it seems that they’re contradicting themselves. because in one of the XL blog entries you’ll find the following statement (I’m quoting Prusa) :

“Question : Does the XL extruder have an accelerometer built in?

Answer: Yes, it does – it’s vital for correct Input Shaper configuration”.

So, accelerometers are vital for input shaper in the XL, but they are totally superfluous for the MK4 ?. Let me raise an eyebrow in disbelief (and then the other ).

RE: Quality issues occured

.........It isn’t precisely a secret that correct input shaper implementation needs absolutely to be calibrated for every individual printer installed on the custom bench/enclosure where the machine is gonna work..............

Is it really like that? Is it that if the frequency only deviates a little does it no longer work?

Nero 3D simply explained it in this video. Of course it is the best with ADXL sensor. But we'll see how it will be.

By the way, Elegoo does the same in the new Neptune4 with Klipper.

In Klipper, many also make the test print to determine the resonances and PA. With the GCODE you can change everything and all the possibilities are open to you.

Perhaps Prusa has noticed too many differences in the XL. A completely different design where the axes are not as independent as the MK4. The belts are much longer etc.

In my opinion, the problem in the pictures comes from the Pressure Advance.

RE: Quality issues occured

I was also thinking that it looks like pressure advance, higher temps also helped a bit, so I don't think this is related to a missing sensor, this looks more like an extrusion issue too me.

When my xl arrives (and got input shaping) I will test it on the xl as well.

RE: Quality issues occured

Have you tried printing with reduced speed in the input shaper profile? I would try to print 20% slower. And/or reduce acceleration. Is still faster than the standard profile. Maybe just reduce the maximum volume.

RE:

I think the "scar" might be due to insufficient cooling. It always happens on the opposite side of where the fan is blowing.

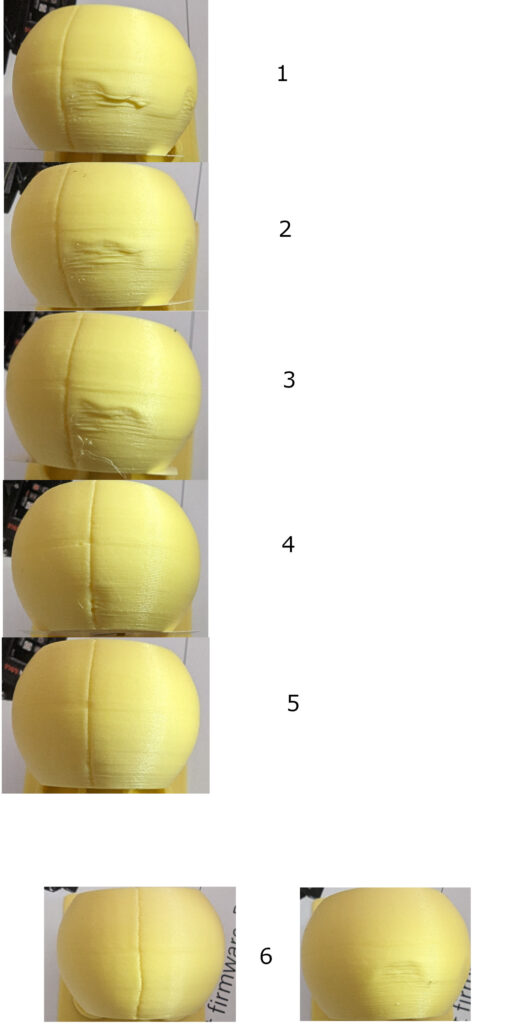

I printed these at 50% scale with the input shaper profile and slightly modified settings:

- 215C Nozzle, 60% fan

- 215C Nozzle, 60% fan, 20% infill perimeter

- 225C Nozzle, 60% fan, 20% infill perimeter

- 225C Nozzle, 100% fan, 20% infill perimeter

- 215C Nozzle, 100% fan, 20% infill perimeter

- 215C Nozzle, 60% fan, seam oriented facing fan. Note issues on opposite side.

Regarding the accelerometer, I also agree it's needed to calibrate individual printers. The resonant frequency of the frame will be different depending how much filament is mounted to it. Hopefully there is a reasonable upgrade path.