what is the cause for different wall thickness?

Dear friends of material deposit...

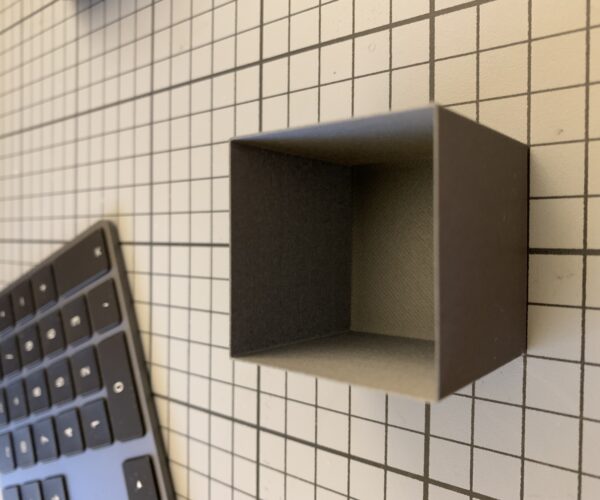

I've a hard time understanding the cause for an inhomogenous wall thickness when printing a single extrusion wall calibration cube.

The cube is printed in spiral vase mode and should obviously be used to nail down the extrusion factor by averaging the wall thickness and comparing it to the intended 0.45mm wall-thickness.

When measuring the walls with my high-precision-caliper/micrometer I found that the measures are quite averaged out on one wall, but differ relatively large on opposing walls. Lets call the front wall "1", the right wall "2", back "3" and left "4"... When wall 1 averages at about 0.43mm the opposing wall 3 would certainly be at 0.46mm in average - wall 2 0.42mm and wall 4 0.47mm.

The front and right wall are always thinner than their counterparts in the back and left!

I rectified the x/z-angle - eliminated torque in the x-axis and still the same...

Can someone help me understand or even better eliminate this phenomenon?

Kind Regards and stay safe!

Chris

RE: what is the cause for different wall thickness?

Things that can influence wall (extrusion) thickness include:

- Filament. If your filament has significant variations in diameter, those will show up in prints. Filament that has been exposed to moisture may not be consistent. These effects should be randomized, however.

- Speed. While the rate of extrusion stays fixed, the nozzle speeds up and slows down. You may notice walls are thinner in the center. Try slowing down and see if walls even out.

- Linear Advance. LA is intended to compensate for nozzle acceleration and deceleration to even flow up. This must be calibrated appropriately for each filament. If not done already, determine an appropriate LA value for each filament. The use of a bowden extruder can aggravate this effect as you are "pushing the string".

- Acceleration and jerk. If your settings are too aggressive, consistency may be affected. LA can only compensate for what you've told it the printer can handle. Backing off acceleration and jerk settings for situations where quality is important can help, but will impact print times.

- Where you measure. In this case, you want to measure the width of an extrusion, not the repeatability between layers. Measure a small portion of the wall near the top, not the entire height of the wall.

- Machine tolerance. In your example, all measurements are +/- 0.02mm of 0.45mm. I haven't seen any formal specifications for the Mini, but 0.1-0.2mm is commonly cited for an expected tolerance in consumer-grade FFF printing. In a $400 printer, you may not get much better.

Of course, you may have other settings that we're not aware of.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: what is the cause for different wall thickness?

@bobstro - everything you said is acknowledged, but what‘s puzzling me is the fact that regardless of the positioning of the cube on the building plate the front and right wall are always thinner than expected and the left and rear wall correspondingly thicker.

The thickness of each wall isn‘t varying that much from one point of measure to another.

And while I would agree to your thoughts on the Mini‘s price-tag and accuracy, I‘m pretty sure that there has to be a systemic error in at least my setup...

Cheers Chris

RE: what is the cause for different wall thickness?

Try moving the z seam position and measure to see if the variances move based in the start of each layer.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: what is the cause for different wall thickness?

@bobstro

it‘s printed in spiral vase mode, so there‘s no seam...

I thought of acceleration issues, but as said, the walls are pretty average, and the same acceleration/deceleration occurs on all of them due to the spiral printing.

The result is the same no matter where I position the cube on the bed - if I rotate it 45° the effect is seen on opposing corners - so it clearly has some x/y relation.

Cheers Chris

RE: what is the cause for different wall thickness?

Wups, was thinking of a different thread, sorry.

Is the thinner wall associated with movement in one direction, the thicker with the opposite direction? Any wobble in the cantilever arm?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: what is the cause for different wall thickness?

@bobstro

The crazy thing about it is, that one wall parallel to the x-axis and one wall parallel to the y-axis is thinner and the opposing walls are thicker - the measurements on each wall differ very slightly from each another on the same wall...

The left wall (when seen from the front) is a thick wall (while thick being relative 😉 ) - the front wall is a thin wall and there's no gradient from front left to right - and the back wall is a thick one - as well without any gradient form left to right.

All measurements are taken with a micrometer-screw with a resolution of 0.01mm and are reproducible any time.

The phenomenon is occurring regardless of the slicer or firmware - in my opinion it has to be hardware related, probably some kind of tilt, but where???

CU Chris

RE: what is the cause for different wall thickness?

Is it related to direction of print? Is a side wall printed back-to-front always thicker than one printed front-to-back? Left-to-right different than right-to-left?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: what is the cause for different wall thickness?

@bobstro

Yes indeed...

The walls printed from right to left (from z-axis outward) and back to front are thicker and the opposing walls (with obviously reversed printing direction) thinner.

Any idea?

Chris

RE: what is the cause for different wall thickness?

[...] The walls printed from right to left (from z-axis outward) and back to front are thicker and the opposing walls (with obviously reversed printing direction) thinner.

The side-to-side variation makes me wonder if the cantilever arm is part of it. Arm gets pulled up slightly one way, down the other. Not sure if the same would apply to the front-to-back though, and I don't have a Mini to look at.

- I wouldn't expect the motors or belts to be sensitive to direction.

- Check bed and X gantry movement for any variation. You could try bracing the arm or checking for any wobble.

- Any variation on how the filament is fed as it moves? Is filament pulled as it moves one way, then loose with less tension as it goes the other? If you coil up some loose filament off the spool and feed it without friction, any difference?

It almost has to be something differing mechanically, at least based on what I'm understanding from your description. The extruder shouldn't be sensitive between directions. Just to eliminate anything odd, try slicing with another slicer to compare.

Other than that, I'm out of good ideas!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: what is the cause for different wall thickness?

may be the cooling fan which is effective on back front side only? In fact when printing the front area it cools only front and the back is left "hot", while printing the back, air flows even on front. just a thought.

Try with rev c mod that put the cooling fan front+both sides and see if this has some effect

RE: what is the cause for different wall thickness?

I had a similar issue thick in one direction and thin in another.

I replaced everything trying to figure it out. ( belts, bearings,motors,rods,buddy board extruder, heat break)

The last part it changed was the Bowden tube between the extruder and heat sink.

Problem solved. Put the old Bowden tube back and had the same problem.

I think the brass olives eventually wear through the tubing causing the filament to get pinched as the x axis moved closer to the extruder. When the x moves away from the extruder the filament is released.

Hence the thicker and thinner extrusions.

RE: what is the cause for different wall thickness?

@adam_pres

This is an interesting approach...

Thanks for sharing - Keep safe and sane!

Chris

RE: what is the cause for different wall thickness?

I found doing this quite useful as well

https://www.prusaprinters.org/prints/30001-prusa-mini-pc4-m6-bowden-fitting-adapter/comments

RE: what is the cause for different wall thickness?

I was having the same issue and can confirm that changing the bowden couplers resolved it. Thank you! I probably would have never thought to check that.

RE:

Dear friends of material deposit...

I've a hard time understanding the cause for an inhomogenous wall thickness when printing a single extrusion wall calibration cube.

The cube is printed in spiral vase mode and should obviously be used to nail down the extrusion factor by averaging the wall thickness and comparing it to the intended 0.45mm wall-thickness.

When measuring the walls with my high-precision-caliper/micrometer I found that the measures are quite averaged out on one wall, but differ relatively large on opposing walls. Lets call the front wall "1", the right wall "2", back "3" and left "4"... When wall 1 averages at about 0.43mm the opposing wall 3 would certainly be at 0.46mm in average - wall 2 0.42mm and wall 4 0.47mm.

The front and right wall are always thinner than their counterparts in the back and left!

I rectified the x/z-angle - eliminated torque in the x-axis and still the same...

Can someone help me understand or even better eliminate this phenomenon?

Kind Regards and stay safe!

Chris

I just received my Mini+ and I have the same issues. I even got myself bondtech extruder & heatbreaker but the issue still there. Marginal differnce but regardless how I oriente the cube it's always on the same side. I have also tried to print the cube on the corners of the build plate but same result

I have adjust everything eSteps, PID, Liner adavcne and flow but same issue. I have also requared the printer

The cube walls always read as

0.45 / 0.45 / 0.47 / 0.48

If you managed to fix the issue please let me know.

RE: what is the cause for different wall thickness?

I was having the same issue and can confirm that changing the bowden couplers resolved it. Thank you! I probably would have never thought to check that.

I printed the couplers in PETG and used Copricorn PTFE the result were the same .. uneven walls thickness

RE: what is the cause for different wall thickness?

I was having the same issue and can confirm that changing the bowden couplers resolved it. Thank you! I probably would have never thought to check that.

I printed the couplers in PETG and used Copricorn PTFE the result were the same .. uneven walls thickness

Which sides of the cube are over and under extruded? In my case it was always the front that was under, the back over and the two sides were right on.

If it's the same for you it sounds like there is still some friction in the bowden tube somewhere, you might try making the bowden tube a little longer to see if that helps.

RE: what is the cause for different wall thickness?

For me if you are looking directly at the printer then the back and left side are abit over while front and right are spot on.