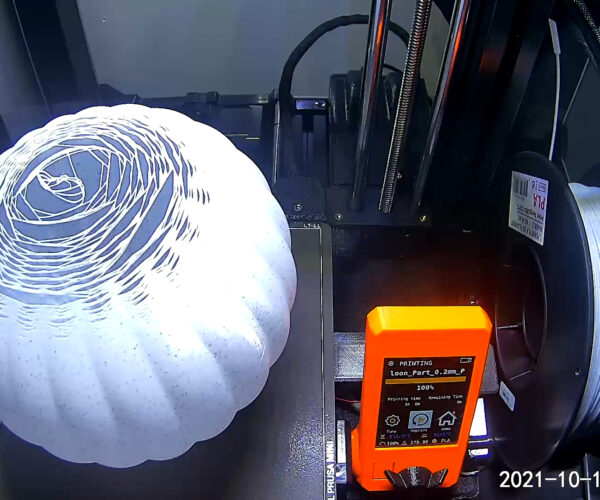

Vase mode tweaks or different approach?

What settings should I be adjusting/tweaking in vase mode to get the top of the balloon to print filled in properly? Or do I need to not use vase mode and take a different approach? The goal here is to print a balloon shaped lamp shade with only the bottom opening. Still kind of new to Prusa Slicer, but trying to learn more each print. I tried changing orientation, but that did not help. Increase extrusion multiplier?

A bit of advice about asking for help on the forum. The single best thing you can do to help others to help you is to save and post a zipped up project file.

Basically load and slice your files as usual and then use File>save project as to save a .3mf file. Take that file and ZIP it up and attach it to a post here. It has to be zipped or the forum won’t accept the file.

Basically there are so many settings for print, filament and printer as well as model positioning, modifiers, painted on supports etc that without the project it’s just impossible to give meaningful advice. A 3mf contains all that information. It allows anyone who loads it to slice with exactly the same settings you are using and allows them to quickly iterate and see the slice preview and if needed to also try printing it.

There are several things you can do to help with vase prints that have such a shallow top, like using a wider extrusion width for example but I think that model is going to be very challenging no matter what settings is used.

Thanks for that! Seems obvious now, but bit of a newbie here. Will do!

3mf file too large to upload

I’ll have to try shrinking it down to fit upload requirements.

Suggestions

- Make sure "Ensure vertical shell thickness" is ON. https://help.prusa3d.com/en/article/layers-and-perimeters_1748

- I'm pretty sure you'll need supports for the innermost surface as it looks like it's mostly flat and the printer can't print on thin air. Either activate supports (on build plate only) or maybe try printing it upside down with supports enabled? This way there would be less filament waste for supports. However this would reduce the surface quality of your print where the supports make contact with the model. You could try to play with the overhang threshold to reduce the support/model contact surface.

Vertical shell thickness is not applicable to VASE mode prints. Neither is support. Vase mode will only work with certain geometries as it is designed to prints a single spiraling extrusion as it goes up. When you do get a geometry that it works with and a set of decent settings it can produce fast and lightweight prints. Designing for vase mode is a skill on its own.

RE: Not vase mode

True, my suggestions do not apply to vase mode. It's more food for thought for the "different approach" alluded to in the original post's title. So, NOT vase mode, very few perimeters, possibly supports, etc. Oh and thinner layers also help with overhangs, which could reduce the area that's problematic on top of your lamp shade.

Both great points. Had thought about printing upside down with supports, but was trying to “massage” some settings like extrusion multiplier to get vase mode to work. Unfortunately, that overhang is just too much for vase mode. Might try upside down with some supports and see how that turns out.

Thanks to you both for the feedback!