Two Extrusion Issues I Cannot Find Answers To

Hello,

I'm very new here and new to 3D printing as well. I purchased a Mini+ a few months back and have been having a blast since. I've encountered a couple issues, but have been able to resolve most of them on my own thanks to this community. I should note the main problem I had: issues with clogging not long after receiving the new printer due to the PTFE tube not being compressed properly within the heat break. The other problem I had straight from the factory was too much idler screw tension - causing filament to get chewed up by the extruder and subsequently clogging the teeth so badly that I was unable to load any filament. I was able to fix both of these, thanks to the guides posted by Prusa, but figured I'd mention it just in case it somehow has an impact here. Unfortunately, I failed to readjust the MINDA probe sensor height after compressing the PTFE tube and applying upwards pressure to the heater block, causing the nozzle to crash down into the PEI sheet when I attempted to recalibrate the first layer height immediately after I performed my repairs. Luckily I was standing right there watching so I was able to reboot the printer and raise the Z axis as quickly as I possibly could. In the event that something like this happens (where the nozzle comes into contact with the bed) is it best to immediately replace the nozzle, or is it not likely that such an event would damage the brass nozzle? It did leave a dent in the spring steel sheet, but I was able to print successfully after this occurred, so I'm not sure if I should replace the nozzle or forget about it.

Recently, however, I've discovered 2 oddities that I cannot explain. I've photographed them and will attempt to attach pictures, but I'll admit the photos aren't great so they may not even be useful for diagnosing. My issues are as follows:

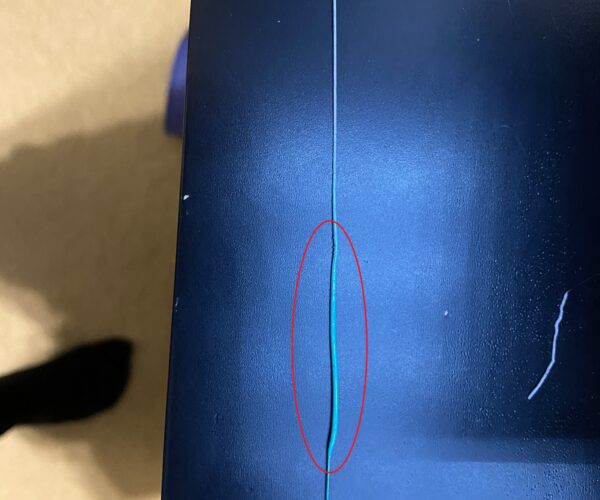

- Sometimes during a filament change, the nozzle will force out a much thicker than ordinary segment of filament. After swapping filament, the purge process begins and the extruded filament is normal width (stock 0.4mm nozzle), then suddenly it thickens up for a short moment before returning to the normal width. Sometimes this same thing will occur when I'm simply unloading filament. I begin the unload process, the nozzle heats up to the required temperature, then as soon as it begins ramming the filament, a thick 'filament sausage' will extrude from the nozzle. I've measured this 'sausage' in the past and it's always around 1.5 - 1.75 mm; almost as if the filament is magically passing through the extruder without ever being forced to slim down to 0.4mm via the nozzle. I've only ever noticed this particular issue occurring with PLA. Moreover, it seems to occur more often with 'silky' filaments, such as the teal color shown in the photo (for reference, in this photo I was changing from the gray PETG shown at the top of the photo to the teal PLA shown at the bottom. Any thoughts?

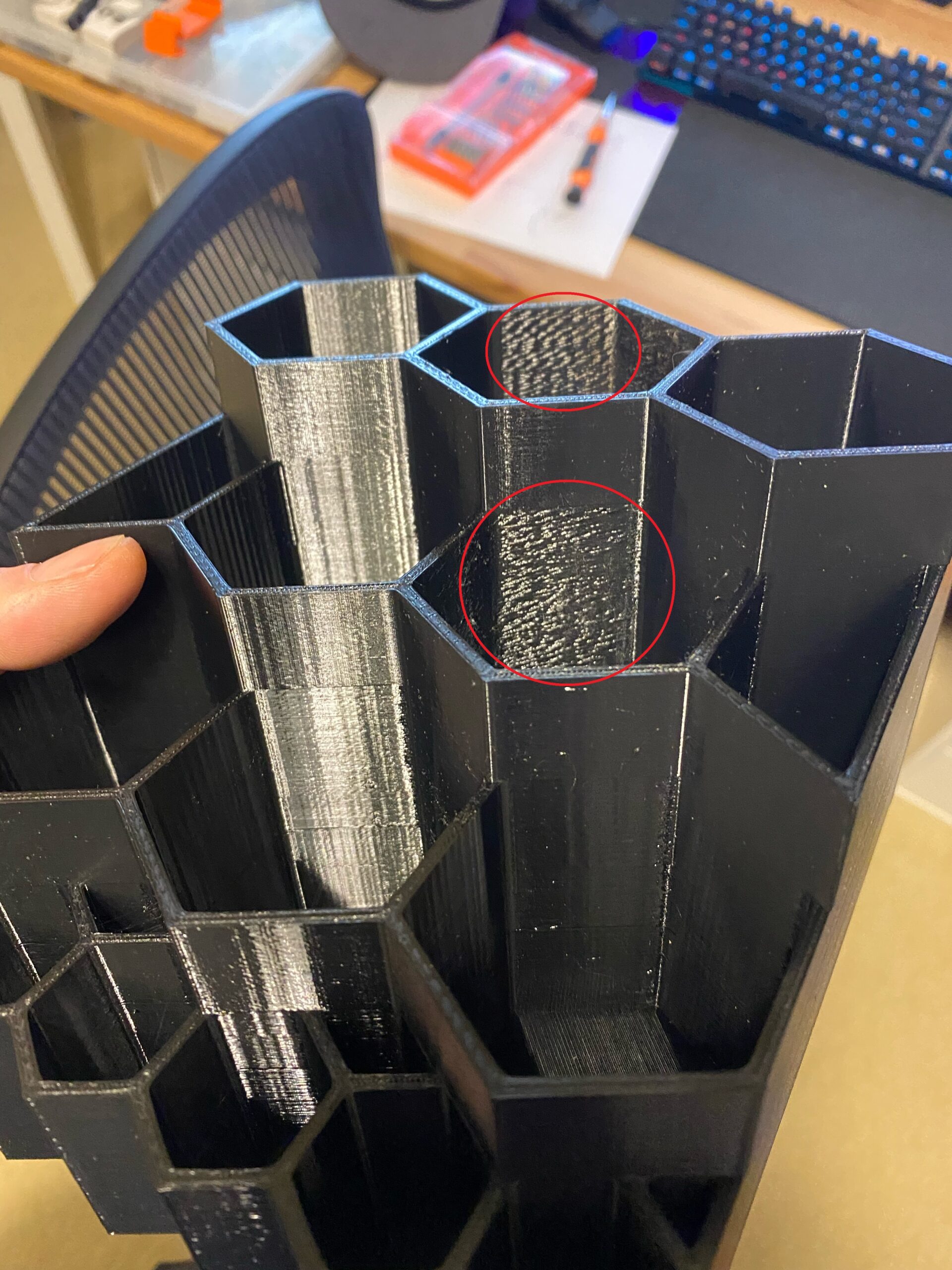

- My second issue has only occurred when printing PETG thus far. I recently found a nice "Honeycomb Organizer" in the Prints section of this website. I downloaded the .3mf file and sliced it in PrusaSlicer using the standard "Generic PETG" filament profile. When I printed the file, everything seemed to go well (some slight stringing at the seam, but nothing insurmountable), except for one or two perimeter wall sections that came out very wavy. I've circled them in the photo which is Overture black PETG. After seeing this problem, I decided to print a second organizer using Atomic gray PETG just to see if I got different results, but I didn't. It came out virtually identical to the much cheaper Overture filament. Is this likely some sort of problem caused by the actual Gcode file, or is it indicative of something more serious like nozzle damage?

If these are stupid questions, please feel free to ignore them and I will continue to poke around on the internet for an answer.

Thank you all for the contributions you make to this site. I know myself and many others would be lost without them. I hope to one day be in your same position of being able to help out instead of adding to the problem. 😊

Take Care,

Dan

RE: Two Extrusion Issues I Cannot Find Answers To

Nozzle crash — Unlikely you damaged it.

Sausage filament — That's what silk filament looks like, nothing to worry about. One of the fun things about using silk filament 🙂

Waves — I admit I don't know. Seems limited only to some walls in that model so maybe it's related to something in the design such as wall thickness?

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Two Extrusion Issues I Cannot Find Answers To

Thanks for your reply, @fuchsr.

Happy to hear my nozzle isn't at fault and that silk filament is as magical as it looks.

I was thinking it must be an issue with the wall thickness too. I'm not sure why, but that's all I could come up with. My concern was that the infill is 'poking' through the wall, somehow...

I may try reprinting using a different slicer, just to see if anything changes