TPU Inconsistent Flow

Having trouble printing eSun TPU 95A on my Mini+. PLA and PETG work fine. Using the generic flex profile. 0.6mm nozzle.

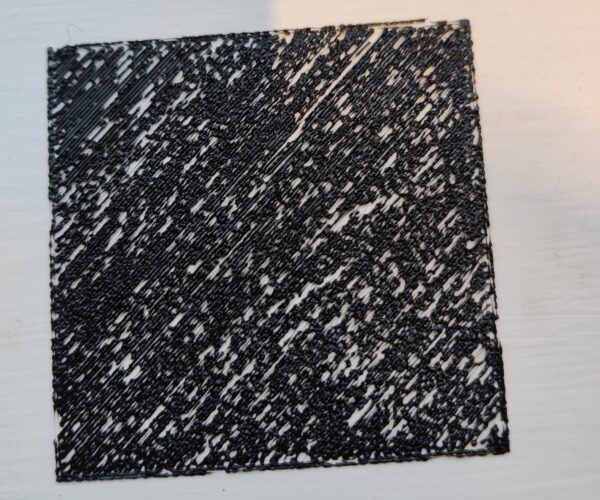

As seen in the picture, there are gaps in the lines of a first layer test. Popping can be heard from the nozzle. Filament came straight out of a new vacuum pack.

This is with max volumetric speed at 0.7, retractions off, and varying nozzle between 210-240 temperature as recommended on filament.

I also slackened the idler several turns.

Any ideas what is causing this?

RE: TPU Inconsistent Flow

This could be a couple of things. I would start by trying to dry it. Being in a Vacuum pack does not indicate dryness.

--------------------

Chuck H

3D Printer Review Blog

RE: TPU Inconsistent Flow

I ordered a dryer yesterday so will try that when it comes.

RE:

I use a food dehydrator and camera dry box. both work great.

I ordered a dryer yesterday so will try that when it comes.

--------------------

Chuck H

3D Printer Review Blog

RE: TPU Inconsistent Flow

I agree with chuck, popping/hissing generally means wet filament. I generally print with sainsmart and ninjaflex, but another thing to consider is temperature and the max volumetric speed. I almost always start with the semiflex profile and adjust temp and/or volumetric speed. I'm printing something with ninjaflex at this very moment. and with steel nozzle I use 246 nozzle, 50 bed, 1.0.8 extrusion multiplier and 1.1 for the Max volumetric speed under advanced settings for the filament profile. Ninjaflex is 85A so a bit softer than the esun stuff and thus can back up in the extruder more easily.

RE: TPU Inconsistent Flow

Had the spool in the dryer for 5-6 hours today so ruled that out.

I had to reduce the temperature to 220 to get it to stop popping, which is within eSuns range.

I found I had to turn up the flow factor in the printers tuning menu from 95 to 150 to get complete lines.

After a lot of trial and error I have the filament profile's extrusion multiplier to 1.74 to get the same effect without touching the flow factor on the printer.

Does the multiplier seem unusually high or is it OK? Max volumetric speed is 1.05 if that matters.

RE: TPU Inconsistent Flow

I've never seen extrusion multiplier set that high. I think the default for semiflex for the MVS is 1.35 and generally that's fine. TPU can be pretty finicky. This ninja flex print I'm doing I had to go down to 1.05 for the extrusion multiplier and up to 248 temp. I went up from 1.1 -> 1.25 MVS. you'll fine that between different colors of the same brand can have different behavior. I'm interested to see when the XL comes out how it handles tpu. have you run any cleaning filament through your nozzle, or done a cold pull? Maybe you have a partial clog? the highest I've personally seen the extrusion multiplier set is 1.23 and that was in a highly tuned ninja flex print of a benchy.

RE: TPU Inconsistent Flow

I've seen that kind of thing when the z was too low also. it creates back-pressure in the nozzle because the rate it's being fed into the nozzle is faster than it can be pushed out.

RE: TPU Inconsistent Flow

I have it working well enough now with a slightly modified Fillamentum Flexfill 98A profile.

RE: TPU Inconsistent Flow

Nice! I'm glad you got it working. it can be a challenge sometimes.

I have it working well enough now with a slightly modified Fillamentum Flexfill 98A profile.

RE: TPU Inconsistent Flow

I just want to try and jump in on this thread if I may. I'm trying to print esun 95a TPU either nozzle X 0.6mm nozzle. My bench results have been quite ugly, zits and blobs, a rough exterior.

Can anyone suggest how I might smooth things up a bit?

I'm using generic TPU slicer settings

RE: TPU Inconsistent Flow

For everyone reading this, if you're forced to raise the extrusion multiplier THAT MUCH (i.e. anything above ~1.10) in order to prevent the filament from under-extruding please be aware this is absolutely abnormal. It most likely means there is something else going on and NO amount of settings tweaking will fix it.

Attempting to push more than 10% the normal amount of filament (that is the meaning of the >1.10 value for the extrusion multiplier) means the filament either must be slipping or is being ground by the extruder gears. If you exclude there's a partial clog (or a backflow due to the excessively high multiplier) because cold pulls come out clean and perfect, then the filament must be slipping.

In such instance, I suggest you open the idler gear door and visually check that the idler is centered and in axis (the idler shaft on rare instances can slip out of its supports), and then also check the idler gear for structural integrity of the teeth and that the grub screw keeping it in place didn't come loose.