Problems with PC from the fifth printout onwards

Good morning:

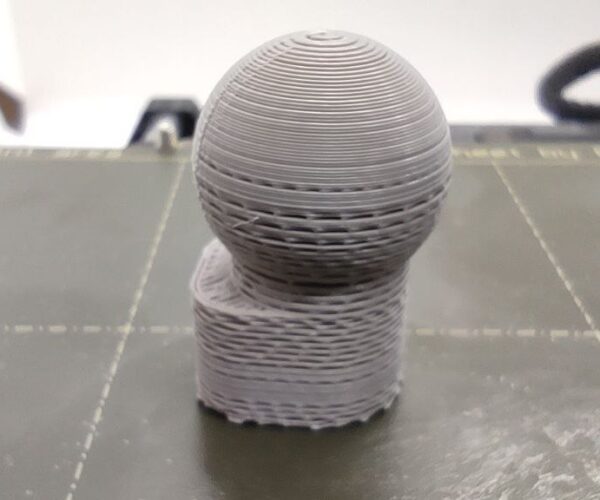

I have a curious problem with polycarbonate. The first impressions I make with PC come out perfect, but as I make more, it's as if not enough material comes out and the pieces remain cracked and fragile. This happens from about the 5th print onwards. Changing the nozzle solves it and it works fine again for another 5 prints. Any idea what could be happening?

I am using:

- Prusa Mini+ with textured film and with smooth film (same problem)

- Hardened nozzle

- Outer casing to avoid temperature changes

- Stick glue on every print

- Prusa PC BLend Urban Grey

- Default profile of Prusa Slicer for PC

Thank you very much

RE: Problems with PC from the fifth printout onwards

Did you adjust the profile for a hardened steel nozzle? I've switched to tungsten carbide because hardened steel required me to adjust all my print profiles. From your description I'd try to print, say, 10 degrees hotter.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Problems with PC from the fifth printout onwards

It seems that you were absolutely right. Raising the nozzle temperature by 10 degrees has completely fixed the problem. I didn't know that using the hardened nozzle required raising the temperature... Thanks a lot for the help!

RE: Problems with PC from the fifth printout onwards

Yeah, that's what they're not telling you 😉 You probably want to run a few temp towers with your nozzle to see how different filaments respond to it.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/