RE: Consistently inconsistent width

Update!

Finally got the parts yesterday (along with “upgrades” to rule everything out)

- Nozzle change - not much improvement, stringing got better

- PTFE and Heatbreak replacement - not much changed either

- Bondtech heatbreak - again, not much difference.

- Bondtech extruder - infill is touching the perimeters better.

After all of that did the extrusion width test cube (vase mode precise one) and all four walls of the cube are different thicknesses.

if the nozzle is moving left to right, down to up i get a very consistent thinner line (~.38 - .40mm)… so thin that one perimeter doesn't bond to the next on other prints/first layer.

if headed the opposite ways, right to left and up to down, i get much thicker lines (~.54 - 60mm)

i was thinking of trying the mesh correction but i doubt thatll fix it as i believe something is torquing the head when moving a certain way… Had a similar problem in my mini lathe and the culprit was an overtightened gib, sadly theres none in a printer 😅

Currently printing another square but even on the z layer calibration you can see that lines going right are much thinner than the ones going left.

X deviation

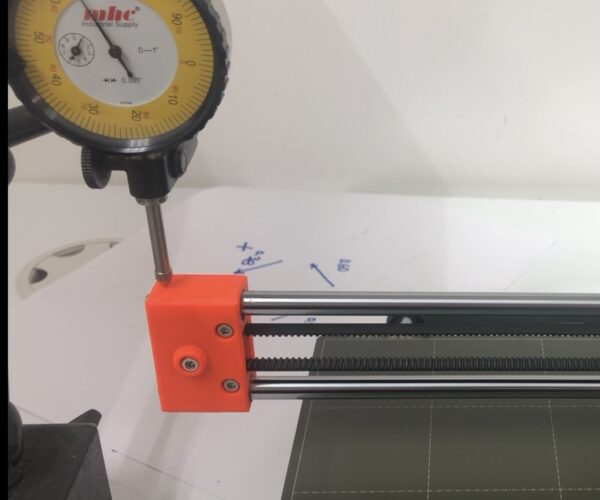

I need to figure out how to attach a video here BUT heres some pics…

(for some reason it keeps clipping the important bits but one is marking 40 and the other is at 65)

The difference between each end of x axis is a whopping .025” (0.635mm) during z layer calibration. Im sure the pinda/mesh level compensates for some but i dunno if this much.

In comparison, just moving the x axis without extruding moves the end about .007” (.178mm)

dunno what to do with this information though 😂 but i though i should share as i find it rather interesting. Wonder if stiffening xz some will help the extrusion width difference

Z movement

Further checking shows there is a .030” movement on the z axis… moving the head to the far end makes the z axis screw rotate slightly. Also don't know if this is common or supposed to happen but it at least explains the high shift between ends…

Correction

Its likely just trying to correct for whatever it measured in the mesh bed leveling. I do find it weird that if i repeat the mb leveling and check between retries, it gets different readings.