Print fails with gaps when using 0.6mm nozzle, worked with 0.4

Problem

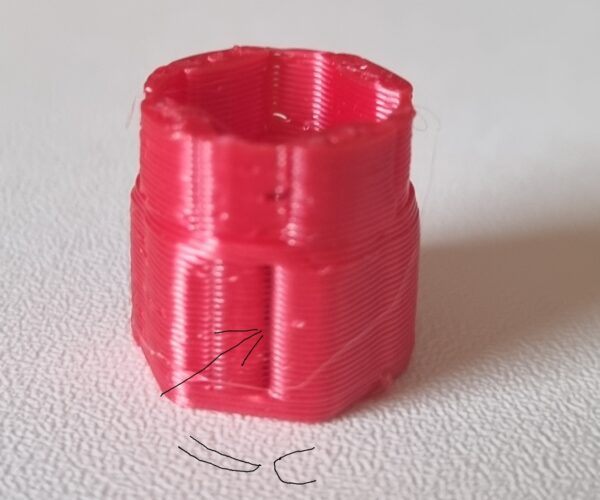

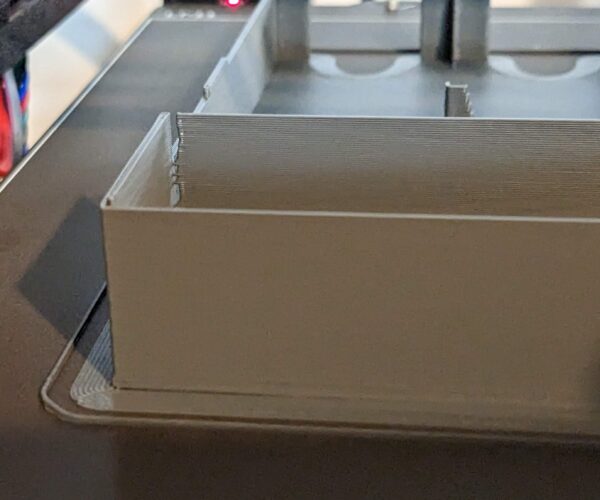

- A model that printed fine with 0.4mm nozzle/PLA, but does not print cleanly with 0.6mm nozzle/PLA. The print has vertical gaps in various places.

- All other models print fine and I have more than 300hours of print time behind me.

- To exclude any hardware issue, I used a new nozzle, new tubes all over, new extruder pulley. And followed all the tips on tuning. And remember, everything else prints well.

What I tried

- I tried PrusaSlicer 2.5.0 and 2.6.0 alpha-5. All the same result

- The issue is worst with 0.3mm and larger layer heights. Gets better with smaller layer height. But does not really go away.

I am lost

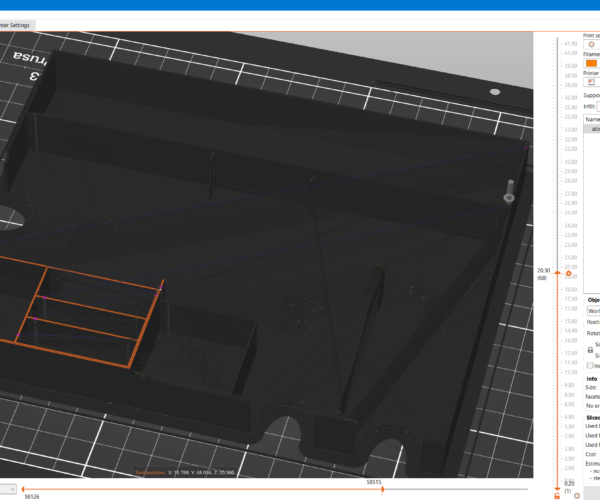

- Is it a problem with my hardware? Can someone with 0.6mm nozzle give it a try and let me know? Print is below 10minutes and .3mf file attached in zip file

- Is it a bug /shortcoming in the slicer only triggered by 0.6mm nozzle?

- Btw, I love 0.6mm nozzle with Arachne....no, I not gonna change my nozzle back to 0.4mm just for that piece.

Comments on image

- The arrow marks the vertical gap. The image does not manage to show the extent of the problem. The vertical gap is "see through" and around 0.5mm wide.

- The black sketch on the bottom is the profile as it prints. Print direction of the left perimeter is "right to left".So more narrow at the start after deretraction.

- Printed with 0.3mm layer height on 0.6mm nozzle and Overture Silk PLA. Standard settings otherwise. And all other models I print are perfect.

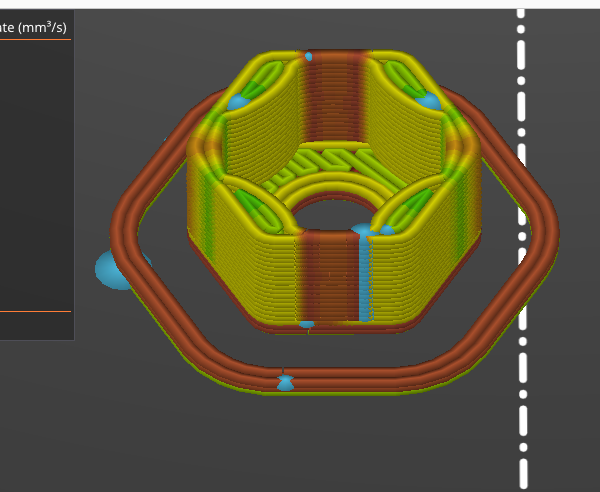

My guess is that it has to to with "deretraction".

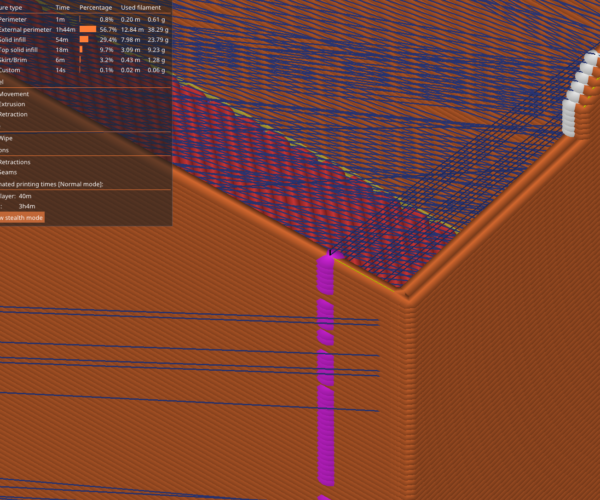

- The issue is caused (on all sides) at the deretraction points (blue). The filament extrusion is too little initially. Or delayed?

- Its worth mentioning, that arachne tries to print a 0.998mm wide perimeter with a 0.6mm nozzle. Maybe thats too much after a retraction?

Model: debug

RE: Print fails with gaps when using 0.6mm nozzle, worked with 0.4

save a copy 0f your prusa slicer setup, as a .3mf file, zip compress it, and attach the zipfile, to your next post

regards joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Print fails with gaps when using 0.6mm nozzle, worked with 0.4

The Prusa slicer setup (.3mf), zip compressed.

for everyone that wants to help hands on. Thank you

RE:

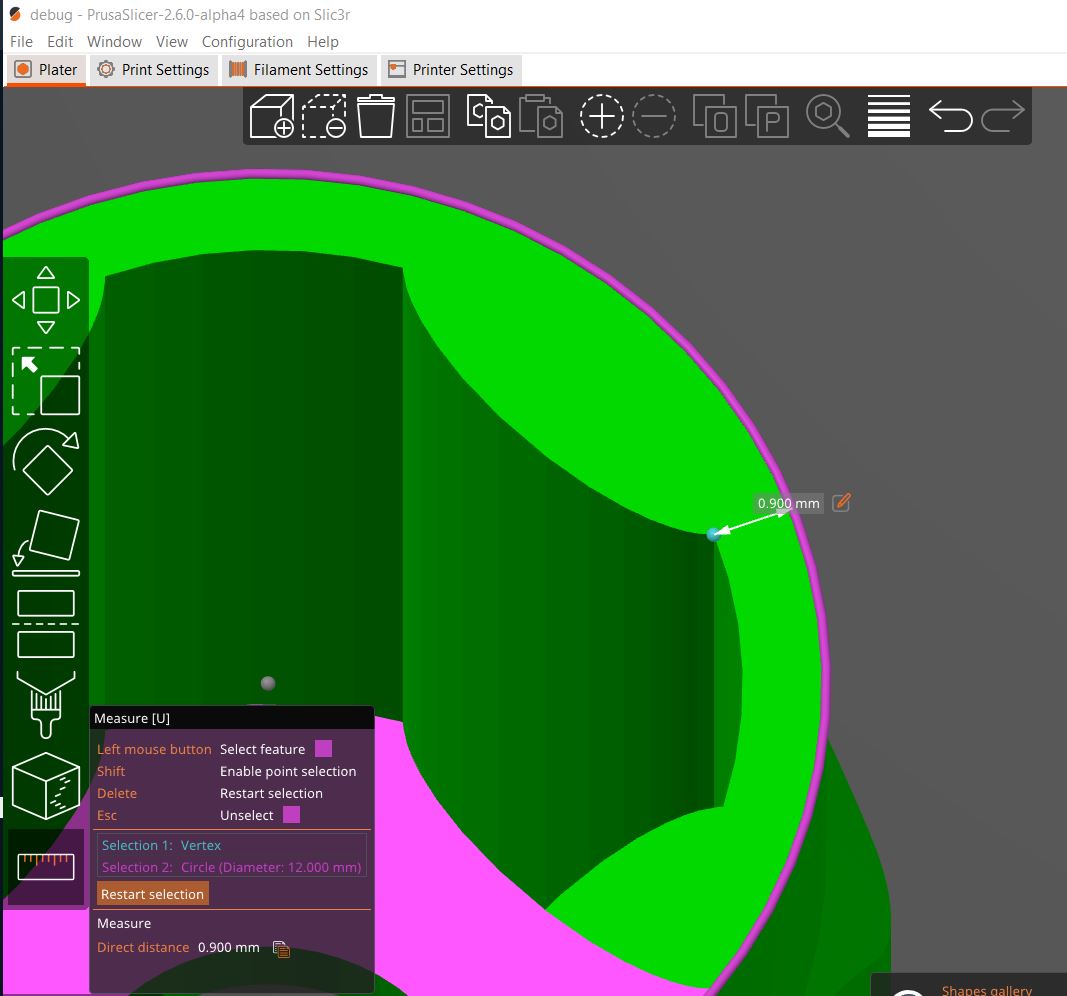

Dear Stefan

I very much appreciate your time. I agree that we should rule out the sub-optimal width. Hence, I adapted the model such that the wall you measured is exactly 0.65mm wide. What I believe to be the optimum width for a 0.6mm nozzle.

I just gave it a try. The result is the same. A clearly visible vertical gap. Exactly at the deretraction markers.

- I would even say, the gap got wider!

RE: Print fails with gaps when using 0.6mm nozzle, worked with 0.4

I had a similar issue with a .8 nozzle, try painting the seam on one of the wider areas where you have multiple walls.

Prusa Mini+ kit. BondTech extruder. FW 5.1.2

Prusa MK3S+ kit. Stock. FW 3.11.0

Prusa MK3S+, used. Stock. FW 3.13.3

RE: Print fails with gaps when using 0.6mm nozzle, worked with 0.4

Let me add that i do not own a Mini...

What you can try:

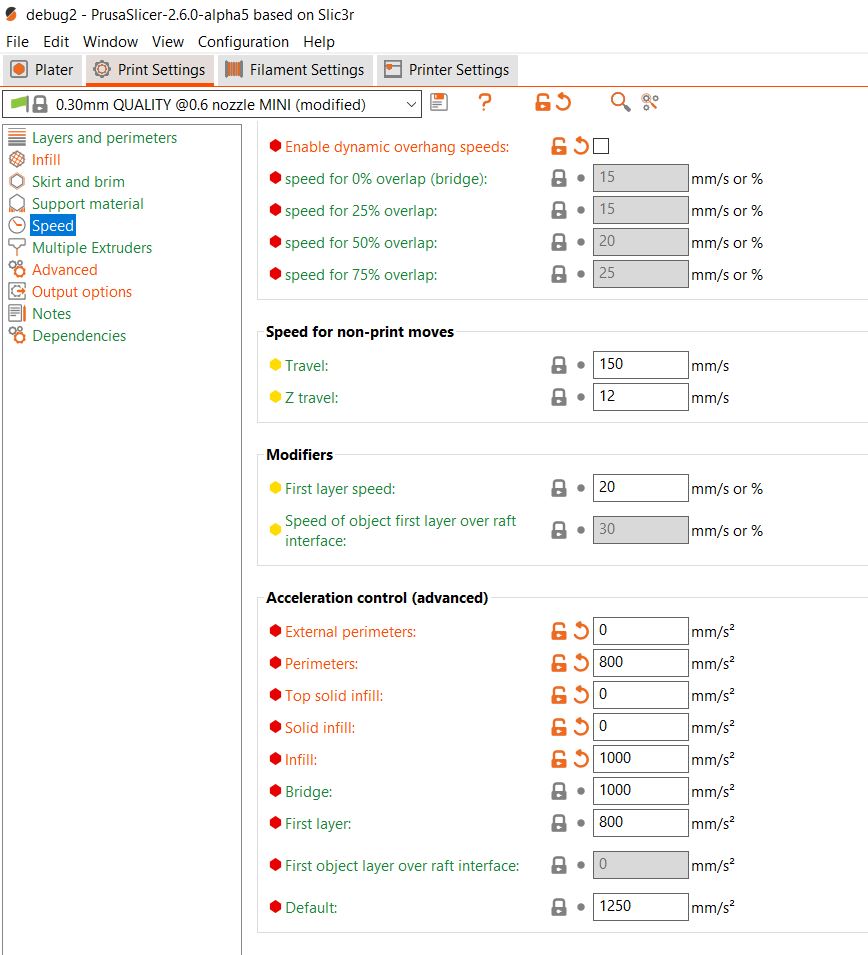

- i recognized that when i open your second project file, in all default profiles (Print, Filament and Printer) there are modified settings.

Especially Print settings>Speed >Acceleration is marked as modified? Reset this to default values.

exactly 0.65mm wide

- to my personal taste, i would print this part with 0.2 0r even 0.15 mm layer height,

as it is so small and it does not matter if it takes 3 min or 5 min to print. - to my own surprise default extrusion width on a mini is 0.68 mm, so adjust your model to this value

- as already suggested, try to move the seam to another place on the model (with seam painting), where the walls are thicker

- Arachne is very promising, however there were also often some strange effects with it...

Very experienced users often suggested to switch "Perimeter Generator" to "Classic" and compare the results. - You mentioned "Overture silk PLA", but there are only predefined settings for Overture PLA,

so there is a chance that this filament profile does not fit and the silk PLA would need other Linear K-settings

RE: Print fails with gaps when using 0.6mm nozzle, worked with 0.4

Tried the print on my mini+.

Generic non-silk PLA with a e3d 0.6 nozzle sliced on 2.5.0 on windows.

Sliced 1 perimiter, 100% infill, 0.3 profile

slice 3fm as well as gcode attached.

DO NOT RUN GCODE! only provided for debug-viewing

Not pretty, but no gaps

Prusa Mini+ kit. BondTech extruder. FW 5.1.2

Prusa MK3S+ kit. Stock. FW 3.11.0

Prusa MK3S+, used. Stock. FW 3.13.3

RE:

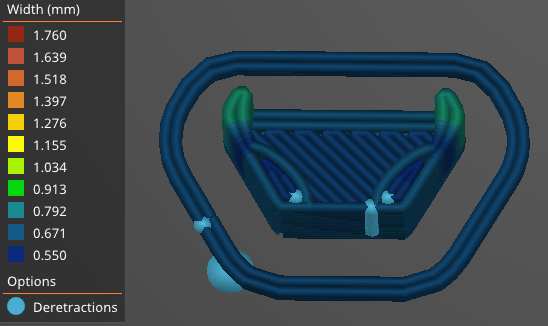

I have the same issue, on multiple models, printing with 0.6mm nozzle on Prusa MK3S+ and near stock settings (modified brim parameters). I slightly modified LA settings, but on stock ones the problem was the same (or worse).

Example of this:

Using Arachne.

Looks like it's trying to start a perimiter after a long move