Ninja Flex

Printing the OpenRC F1 car on my Mini. Going to print the tires tomorrow using NinjaFlex. I did not see a NinjaFlex filament profile in PrusaSlicer. Is the the "Generic Flex MINI" profile good enough?

RE: Ninja Flex

...so that was few days ago - how did it go?

Texy

RE: Ninja Flex

My shipment of ninjaflex never arrived (wtf Amazon?), so I am waiting on a new order to arrive tomorrow (Friday). Will give it a shot on Saturday.

RE: Ninja Flex

Great- keep us all informed, I am sure many will be interested.

Texy

RE: Ninja Flex

@mreynolds0404

It looks like humidity in flex filament (due to gaps). It is good to use dry box for flex, then it will be printed almost like PLA 😉

RE: Ninja Flex

@texy

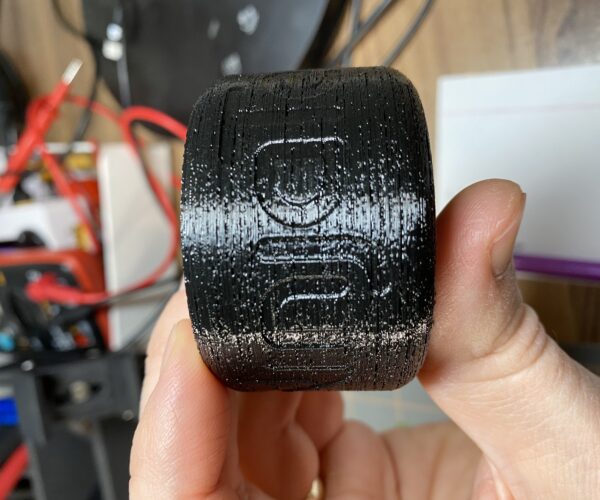

Yeah it’s comparable to a real RC tire.

RE: Ninja Flex

These are some pretty cool results. do u think the gaps are caused because of the Bowden setup retraction etc?

Original Prusa Mini + Smooth PEI

Prusa Slicer 2.6.0

RE: Ninja Flex

@geoper2

I guess it causes humidity in flex filament. It has to be dry as hell.

RE: Ninja Flex

@mreynolds0404, did you have any issues with the extruder not feeding in filament or the nozzle getting jammed? The first layer or two was fine but then nothing was coming out of the nozzle using the generic flex profile for the Mini.

RE: Ninja Flex

@bradmcgonigle

Maybe I got lucky, but I had no issues. Worked on the first try. Did you loosen the idler screw like the manual said?

RE: Ninja Flex

@bradmcgonigle

Maybe I got lucky, but I had no issues. Worked on the first try. Did you loosen the idler screw like the manual said?

I even looked in the manual to see which sheet to use but I guess I should have read the ‘highlighted’ note on that page!!! Haha 😉

I’ll loosen the idler and give it another shot. Thanks!

RE: Ninja Flex

@mreynolds0404 I'm not sure it would matter do you have the filament sensor? I've tried loosening the idler screw as far as it will go and a few steps in-between but I'm still not able to get the NinjaFlex to feed properly.

RE: Ninja Flex

I do have a filament sensor.

RE: Ninja Flex

For me the nozzle temp must be at least 250C for Ninjaflex to print something. Also found that I had to remove filament sensor to get rid of the extra reistance it makes. After that I will get some kind of results with ninjaflex. But I'm still far from being satisfied since maybe 25% of the prints end as they should. Still see a lot of stringigg. Retraction is set to 0, speed 20mm/s.

Has anybody found good settings?

RE: Ninja Flex

For me , I just used the default Flex material profile for the Mini. I was able to print 4 of these tires without issue.

RE: Ninja Flex

@mreynolds0404 would you mind sharing the gcode or PrusaSlicer 3mf for that file? I'd love to give it shot to see if for whatever reason I get different results then what I've been getting. Also, you are definitely using NinjaFlex TPU and not their Cheetah or Armadillo versions?

Like @riho, I've had very limited success by using the Generic Flex Mini profile but setting the temp to 250C-255C but there is ton of stringing and I'm still not getting a solid flow out of the extruder. I haven't tried removing the filament sensor yet but it doesn't sound like @riho is having much more success with it removed anyway.

RE: Ninja Flex

the quality isn't bad at all but it will never print more than 30min before it will jam the nozzle.

RE: Ninja Flex

Here is my tire gcode.