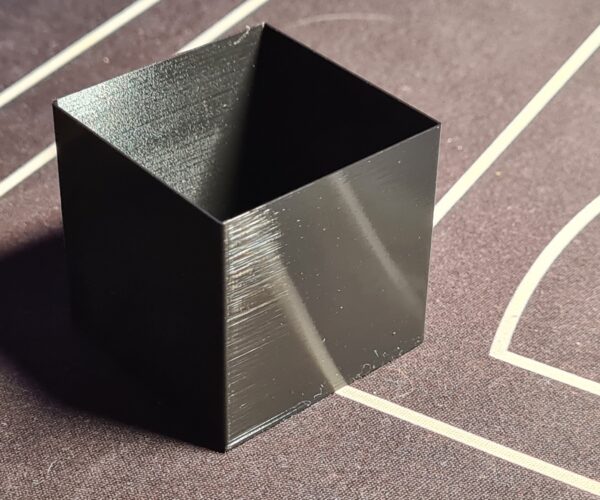

I should've tested it using PETG..

I thought that those layers look a lot like not enough cooling.. So I opened whole top of lack enclosure (I've read that for PLA it might be too hot) and the result is fantastic!

I'll redo same test with PETG, but hopes are high 🙂

I don't recall that enclosure was mentioned before in this thread...

Yes, printing PLA in a closed enclosure is not a great idea. Even PETG does better in my hands without. Actually, I do have all my printers in enclosures but I leave the front door open for PETG and PLA.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

PETG also came out great and that was fully enclosured.

Now it's going on other print, I heard few clicks. I added loctite on positioning screw of extruder motor pulley, so my suspision goes to motor. Print so far goes well but it's just few layers in.

I'll see if prusa support can help on this one, new motor is new expenses :/

I don't recall that enclosure was mentioned before in this thread...

Yes, printing PLA in a closed enclosure is not a great idea. Even PETG does better in my hands without. Actually, I do have all my printers in enclosures but I leave the front door open for PETG and PLA.

I instaled it recently, beginning of this week - toghether with lack enclosure I removed prusa base legs as unfortunately printer is too high for single enclosure like that. I wanted to install it to control humidity inside (with closed enclosure it can drop below 40%) however if cooling is not enough I have to figure something else (like dryer + coolinf fan for enclosure itself).

loctite

Which screw did you loctite?

PETG also came out great and that was fully enclosured.

Now it's going on other print, I heard few clicks. I added loctite on positioning screw of extruder motor pulley, so my suspision goes to motor. Print so far goes well but it's just few layers in.

I'll see if prusa support can help on this one, new motor is new expenses :/

--------------------

Chuck H

3D Printer Review Blog

Consider a filament drybox. It really helps!

Hi,

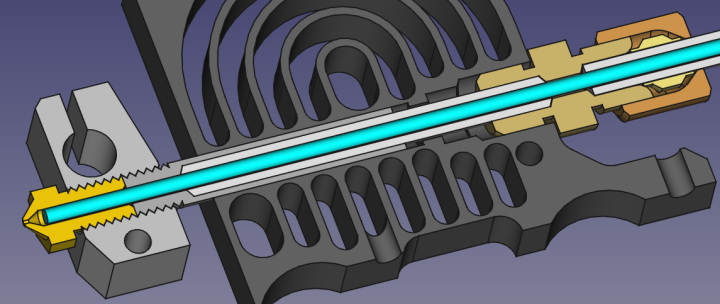

I've had similar issues when I started to print PETG. PETG is really moisture sensitive. I couldn't print with the spool out in the open for more than a few hours, before starting to notice excessive stringing (moisture levels in this room were about 60-67%). The solution for me was a filament dry box. I built one myself from a plastic storage container with lid, some rubber sealing tape, a long PTFE-tube and a 3D printed coupler, that passes the tube through a hole into the storage container. It works as follows:

I drilled a hole in one of the walls of the storage container and glued my PTFE-coupler into that hole. Then I put the rubber sealing tape on the inside of the lid. Next, I inserted the PTFE-tube into the container through the coupler, put a spool holder inside the container, fed the filament from the inside through the tube, into the printer. The tube is long enough, that it reaches right to the printer. Lastly I put some color change silica packs and a hygrometer inside the container and closed the lid.

Now I have a fully enclosed spool and filament feed path right to the printer. After some time (half a day or so) the moisture level inside the container stabilizes at about 20%. This really improved print quality substantially! The moisture levels remain at tolerable levels for several weeks(assuming you don't open the container too often, or for extended periods of time. I bake the silica packs once moisture levels reach about 30% and the color of the packs has changed. I don't use an enclosure for my printer, as for PETG It isn't really necessary.

I hope this helps.

Which screw did you loctite?

Small set screw that holds extruder motor gear - I figured this one should not come loose from vibrations and potentially start skipping steps and loctite is best for that.

Posted by: @sebastian

I built one myself from a plastic storage container with lid...

That is not a bad idea - I could mount such box below lack table, and feed it to printer through hole. Food for thoughts (and project :D).

I wanted to have printer enclosed as it can only be placed in living room, enclosure reduces noise coming from printer. Don't get me wrong it's pretty quiet, except for layer infills and this absolutely worst placement for print fan - I already have second fan, both are already resonating on bearings (fan axis gets bad treatment on Y axis fast movements) - I am printing fan duct mod that puts this fan on an angle and that should further reduce noise and help with cooling (hopefully enough to have ecnlosure closed for petg). FYI - https://www.prusaprinters.org/prints/52553-prusa-mini-rhd-front-fan-duct

Yeah support so far only mentioned stuff I already did couple of times, and when they heard about bondtech heatbreak, straight up refused to help more - which is dunny as original heatbreak was making longer prints (8+ hours) just completely fail, and clicking was there already..

I replaced all ptfe tubes in system with new ones, cleaned whole path of filament.

I even unscrewed tension pulley to the point when extruding stopped - still clicking!

This is infuriating.. Yesterday to make things worse after 3 days of good prints it straight up clogged on same filament (Prusament PLA), with no enclosure around it. That made me strip it down and clean today..

check this out

I found a thread were someone seems to have found a solution to extrusion problems on the mini. I don't know if it is the exact same issue you are having, but maybe it helps:

https://forum.prusa3d.com/forum/hardware-firmware-and-software-help/hot-end-assembly/

They were talking about the hot end sticking out of the heatbreak too far.

RE:

Maybe its little too late 🙂 (no activity more than 10 days) but if you want to try something ? I fixed my extruder clicking by opening the extruder, removed the motor, adjusted the gear screws to be inline (the motor one was little too high) and then till tightening back the screws that hold the motor I keep pushing the gears close. After that my extruder stopped to click. Anyway few days later bondtech ifs took its place.

RE:

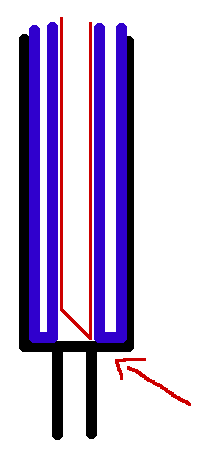

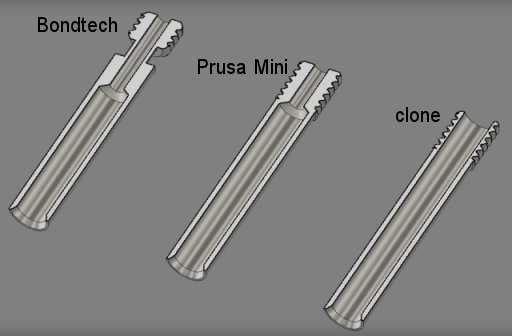

Hahah pretty much same story here. Difference was I think some clogs were so bad that gears pushed and bent plastic parts resulting in gears not being aligned and having space between in certain position - I was asked support to reprint them and it worked for 2 days. During this time bondtech extruder arrived and I'm honestly shocked how good it is compared to original one. To the point that I feel it's a big mistake for Prusa to not include that in first place (maybe mini+ v2?).

Also, I removed bondtech heatbreak as I had clogs and I'm not that experienced with custom PID setup. I found this thread ( https://forum.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles/strange-extrusion-problem-using-bondtech-extruder-and-heat-break-on-prusa-mini ), which showed me that I'm not alone, and unless you're experienced user and want to tinker a lot, this product is just not on level to be recommended for everyone. For now bondtech heatbreak is waiting for better times (I am thinking slowly of moving towards v6 or mosquitto, but since printer is flawless now, I parked it).

RE: Issues with PETG on brand-new mini+ (preassembled)

...Also, I removed bondtech heatbreak as I had clogs and I'm not that experienced with custom PID setup...

Don't take it personal, but I think you just didn't install Bondtech heatbreak properly. In my opinion, this heatbreak (& extruder) upgrade is worth every cent. Keep heatbreak in safe place, because you will search for it.. sooner or later 😉 .

About PID... According to Prusa (at releasing firmware v4.3.3), there's no need to change PID value for Bondtech heatbreak -anyway, stock PID value shouldn't be the reason for clogs.

Wish you successful printing

[Mini+] [MK3S+BEAR]

RE: Issues with PETG on brand-new mini+ (preassembled)

Keep heatbreak in safe place, because you will search for it.. sooner or later 😉 .

I do, I very much would like to have it as I understand it's advantages. I spent several hours tinkering around it, thinking that there has to be something wrong with me setting it up. All problems with inconsistent extrusion went away after switching to original heatbreak.

I tried around 8 different ptfe tubes, different lengths, chamfered or not. Those that were able to finish first layer without underextrusion, were fine, however eventually they all resulted in clogs. And most of the times what I noticed was that when performing cold pull, I sometimes couldn't even push filament through. Weird? And not from filament being stuck, that was on 260C. I was hitting edge of heatbreak, which I marvolously drawed to their support.

This I think caused most of problems, to the point where one clog pushed out ptfe brass fitting (but that was partially on me as I replaced bowden tube and fitting was too loose).

Could be bad ptfe tube (but all?..) or heatbreak, or I'm just super unlucky.

Even if filament was going through normally, I was having really hard time with inconsistent extrusion, which aligns with what people experienced in thread I mentioned in previous post. I read whole thread and saw people fighting with temperatures, calibrating default profiles etc. There is a high chance a bunch of people cannot install it correctly, but I simply ran out of patience. I initially bought this printer intentionally to not have to tinker in it much, I could buy a clone or a cheaper printer, which could as well have same issues for less money.

Point is, going back to original heatbreak and switching extruder to double geared one, resulted in me finally not having to look every 2' at printer checking if it's not gonna fail another print.

Maybe I'll go back to this heatbreak if printer shows signs of heatcreep (when I finally finish up enclosure with fans, filters etc), for now it works and with new extruder it prints flawlessly so I lost interest in improvements for now 🙂

At least those - I'm still looking for ways of making it more quiet (currently most annoying sound is resonating print fan bearings at certain speeds).

RE: Issues with PETG on brand-new mini+ (preassembled)

Point is, going back to original heatbreak and switching extruder to double geared one, resulted in me finally not having to look every 2' at printer checking if it's not gonna fail another print.

Maybe I'll go back to this heatbreak if printer shows signs of heatcreep (when I finally finish up enclosure with fans, filters etc), for now it works and with new extruder it prints flawlessly so I lost interest in improvements for now 🙂

At least those - I'm still looking for ways of making it more quiet (currently most annoying sound is resonating print fan bearings at certain speeds).

Going back the original heatbreak and extruder will help you talk to support better. I have not idea how to help you with the noise. My Minis are the quietest printers I own by far.

--------------------

Chuck H

3D Printer Review Blog

RE: Issues with PETG on brand-new mini+ (preassembled)

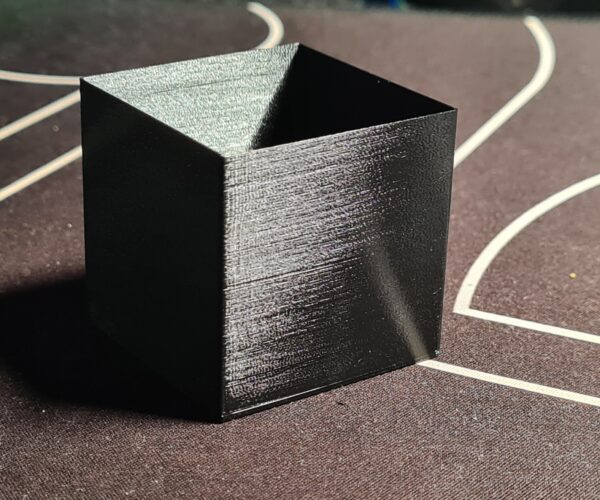

Hmmm... that's not how Bondtech heatbreak should look inside

-there's a chamfer at the end of PTFE tube, which has the same angle as stock heatbreak. The difference between these two is, that Bondtech actually has heat-break area, and PTFE tube ends above that area.

Don't get me wrong, I'm not trying to convince you into anything. It's just, that it works excellent for me. I only used PLA and PETG so far (ASA spool is waiting for the right object) and I never had clog or any extrusion related problem. Yes, I know, it can happen anytime because of whatever reason -but I wouldn't blame Bondtech heatbreak for that.

But at the end, everyone should use what works for him.

[Mini+] [MK3S+BEAR]

RE: Issues with PETG on brand-new mini+ (preassembled)

Hmmm... that's not how Bondtech heatbreak should look inside

I guess you don't appreciate my drawing skills 🙁 it was simplification

Internal diameter of wider part for me is 4.21mm which gives ~0.1mm for ptfe tube to move. It shouldn't as chamfer should place it perfectly, but that's what I experienced - in rare occasions I couldn't push filament through heatbreak. I'm getting a replacement and I'll be extra causious about chamfering, angle, length, anything that could be potentially human error and we'll see.

For ASA, not sure if you're interested but I just got my spool and I'm printing this tomorrow:

https://www.prusaprinters.org/prints/74324-e3d-v6-hotend-fan-duct-prusa-mini-x-carriage-repla

I love this fan duct model and I have one placed in front of printer, however it looks ugly as hell and I was happy to see someone merged it with X-carriage of Mini 🙂

It's supposed to work with hotend, the only thing I'm not sure is clearance from heatbed (specifically two screw that align PEI sheet).

RE: Issues with PETG on brand-new mini+ (preassembled)

I guess you don't appreciate my drawing skills 🙁 it was simplification

-no problem with drawing, I only though you're saying that area at the bottom of PTFE tube is flat 🙂 .

Internal diameter of wider part for me is 4.21mm which gives ~0.1mm for ptfe tube to move. It shouldn't as chamfer should place it perfectly, but that's what I experienced - in rare occasions I couldn't push filament through heatbreak.

Internal diameter clearance isn't really that important. If chamfer on PTFE tube is made right (centered), then PTFE tube will center itself and filament will go smooth trough whole assembly.

Bondtech says, the length of PTFE tube inside heatbreak should be 36mm. If you're not sure about length accuracy (when making chamfer), then maybe you increase the length by half a millimeter. Important is, that it's not shorter than 36mm.

About that fan duct.. I'm interested, of course 🙂 .

Yes, it looks promising for sure and I'm really curious about part cooling differences. As you mentioned, those two screws on the back of the bed can be problematic.. maybe you'll need to shorten them with Dremel.

[Mini+] [MK3S+BEAR]

RE: Issues with PETG on brand-new mini+ (preassembled)

Time to edit the post is really too short in this forum!!

In my previous post, hotend with stock heatbreak is shown -assembly for Bondtech is the same, though.

[Mini+] [MK3S+BEAR]

RE: Issues with PETG on brand-new mini+ (preassembled)

Yeah the only thing that comes to my mind is that ptfe tube was not chamfered properly. Once new heatbreak comes I'll sit back to tinkering.

Fan duct is awesome ;] No problems with clearance, but you have to print fan cover as original pinda mount is incompatible.