Issues with 0.05 and 0.1 mm resolutions (mini+)

I recently got my mini+ (first 3D printer). So far I have only used the .stl files I found on this website. I have had no issues printing several items at 0.2mm resolution, including the Dino bag clips that have moving parts.

When I try and print files that are set 0.05mm resolution or 0.1mm resolution the first layer is fine, but on all subsequent layers the nozzle catches and digs into the previous layers. I made sure in prusa-slicer that the resolution and layer heights match.

Using the same files, when I change the resolution and the layer heights to 0.2mm the items print fine. Does this indicate that there is something off with the z axis control, or my printer settings?

Thank you in advance for your help,

Rich

RE: Issues with 0.05 and 0.1 mm resolutions (mini+)

No, it sounds like you don't have your settings dialled in. Nozzle catching on the part is*usually* caused by either the part lifting up from the bed (due to improperly set z height or bed cleanliness) or slight over extrusion. It could also be your infill choice as some infills patterns'cross over' each other on the same layer and leave a raised spot. Basically the lower the layer height used the better your settings need to be dialled in to reflect reality. It sounds like it may be a bit of over extrusion.

With a 0.2mm layer height, lets say you have a 1% over extrusion as an example. Now the nozzle as it travels will iron any raised spots where the over extrusion has collected as long as the bed adhesion is good. Otherwise the bump will cause the print to detach. Ok, now go down to 0.1mm layer height. You still have a 1% over extrusion but now you have twice as many layers so the buildup in the same space is now 2%. Now drop it to 0.05mm. 4% extra in the same space.

So dial in your filament settings. First thing is to accurise the physical things. Like check that the extruder steps per mm is correct. When told to extruder 100mm of filament it should extrude exactly 100mm, not 100.1 (over extrudes) or 99.9 (under extrude).

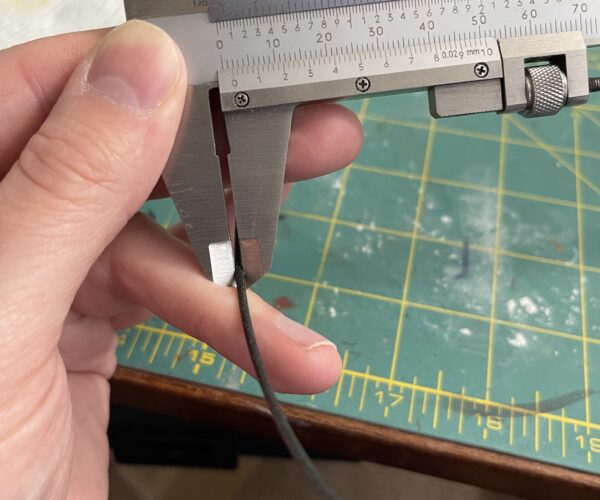

Once that is confirmed you measure your actual real world filament diameter with a caliper. Measure multiple spots and positions around the filament to work out the real average. The plug that number in to the filament settings instead of the default 1.75mm. If your filament is 1.755, then guess what, you will be over extruding.

This step is a pain as it varies from manufacturer to manufacturer and sometimes from roll to roll. Its why buying 'good' consistent filament is important if you are printing with lower layer heights.

Once that's done you can be confident that when the printer is instructed to extrude a certain amount of plastic it is doing. People go straight for messing with things like extrusion multipliers when they see flow issues without checking the real basics first.

Btw the reason the first layer is ok is that usually the first layer is set to 0.2 in Prusa Slicer, even on the 0.1/0.05 profiles.

RE: Issues with 0.05 and 0.1 mm resolutions (mini+)

Thank you for taking the time to help, I appreciate it.

So I am using Prusament PLA, I measured it with the only calipers that I have (analog, so they are not going to be accurate enough) and it appears that the filament is approximately 1.75mm

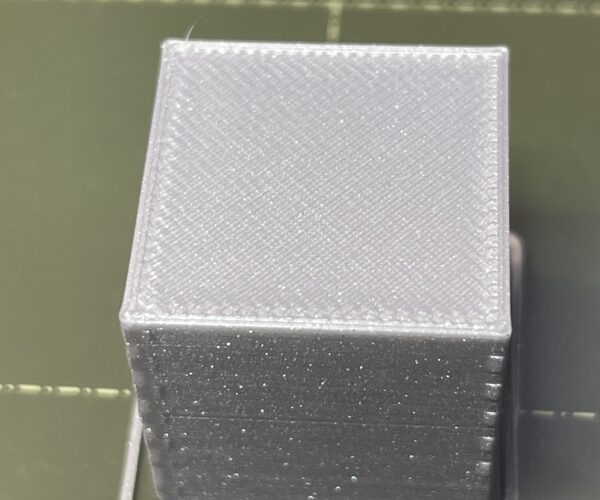

I then printed a 1x1x1 inch cube and it was dead on (again using analog calipers) on all faces

The top of the cube did not have any of the defects that I saw in this article: https://help.prusa3d.com/en/article/extrusion-multiplier-calibration_2257/ : but there were some "knobs" along two of the vertical edges of the cube

I then printed 6 small boxes in a grid pattern that were 5x10x2 mm and measured all 6, the X and Y values were perfect but the Z values were 2.15mm instead of 2mm.

Should I try adjusting the extrusion multiplier?

RE: Issues with 0.05 and 0.1 mm resolutions (mini+)

I would also add that for the life of me I can't see any improvements in print quality with any layer height less than 0.1, using the stock 0.4 nozzle.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Issues with 0.05 and 0.1 mm resolutions (mini+)

What filament do you have selected in your slicer? Does that match the filament that you are printing with?

RE: Issues with 0.05 and 0.1 mm resolutions (mini+)

I am using the prusament PLA filament and have that selected in the slicer, have you had any issues with Prusament?

RE: Issues with 0.05 and 0.1 mm resolutions (mini+)

I am using the prusament PLA filament and have that selected in the slicer, have you had any issues with Prusament?

Never.

RE: Issues with 0.05 and 0.1 mm resolutions (mini+)

Updated the firm ware and restarted the wizard, now it is working great. Had to change the nozzle height an additional 0.2mm after the reset. Thanks again for your help

RE: Issues with 0.05 and 0.1 mm resolutions (mini+)

Updated the firm ware and restarted the wizard, now it is working great. Had to change the nozzle height an additional 0.2mm after the reset. Thanks again for your help