I can’t figure out one of my Prusa Mini issues

I have been having some very challenging issues with just one of my Prusa Mini printers. Just for some background I bought one printer directly from prusa preassembled and it’s working great. The other one I found on eBay and I have tried to bring it up to speed but I have been having very little luck with consistency. The one I am having issues with is the original Mini not the +. I went through and updated to the new super pinda. I was initially having issues with the extruder clicking so I went through the procedure of pushing up the ptfe tube in the hot end and prints have been coming out better but as they get larger towards the top of prints I am running into failures. The bed has been cleaned with dawn and alcohol multiple times I think there is something small I need to tweak to get it performing like my other machine. Please help any information is valuable at this point I’ve been struggling with this for about 3 weeks now I am finally jumping into the forums with my own post for the first time. In advance thanks for any replies and happy new year. FYI same print same gcode. Black failure is prusa net pla and the white one is the cheapest pla on Amazon which is why I’m surprised it’s out performing the prusament lol

RE: I can’t figure out one of my Prusa Mini issues

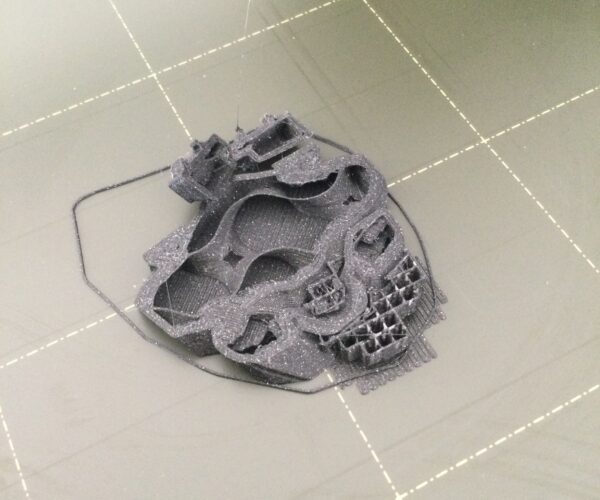

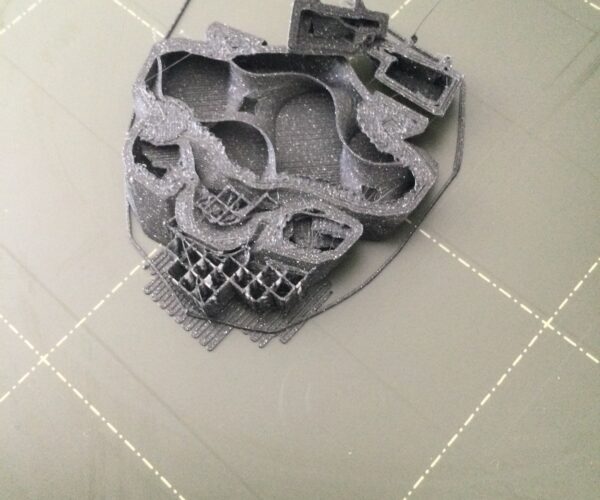

Upon further look it seems the only issue with the print is the printing of support my printer is struggling with mainly printing support material

What happens if you switch filaments? Does the problem stay with the printer or move with the filament?

Cheerio,

RE: I can’t figure out one of my Prusa Mini issues

It stays with the printer my other printer doesn’t miss a beat with the same filament I tried to switch the support style in the slicer and it’s printing now I will update with a picture soon

RE: I can’t figure out one of my Prusa Mini issues

After following the guide on this. It seems like it’s more of a work around then an actual fix.

https://help.prusa3d.com/en/article/failing-supports_1807/

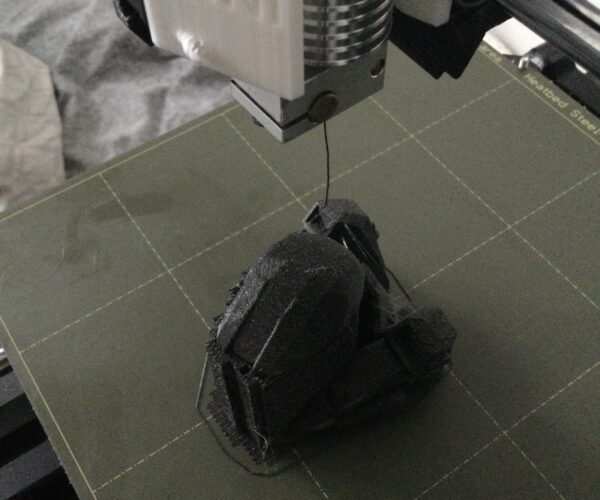

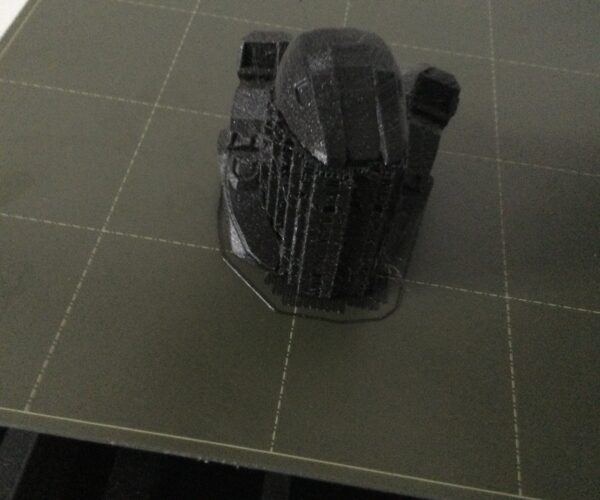

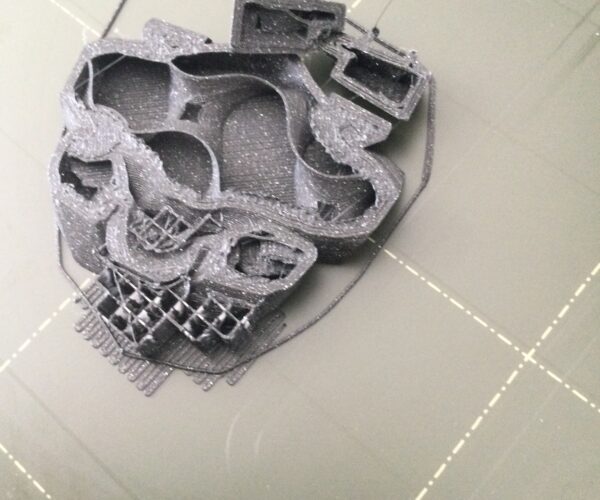

I tried playing with the support settings but I’m left at this:

Do you have any way of checking the temperature at the nozzle? Checking the reported figure is accurate...

Cheerio,

RE: I can’t figure out one of my Prusa Mini issues

Honestly not really, how would you recommend I do that? Is the theory that potentially it is giving me an inaccurate reading and therefore maybe the heater cartridge is out of life? Just trying to see what direction you were going @Diem thanks for the replies.

RE: I can’t figure out one of my Prusa Mini issues

If your temperatures are low it wouldn't be the heater cartridge that's the problem it would be the thermister. Prusa's have thermal runaway protection so if the heater cartridge can't get the temperature up to the temperature the thermister thinks it should it would stop the print with an error. Since you're not triggering thermal runaway then the cartridge can reach the temperature set by the thermister. Try re-slicing and raise the temperature up by 10 degrees, see if that helps.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: I can’t figure out one of my Prusa Mini issues

Ok Bob, Thanks for the reply, I will do that now and take a picture of the results

RE: I can’t figure out one of my Prusa Mini issues

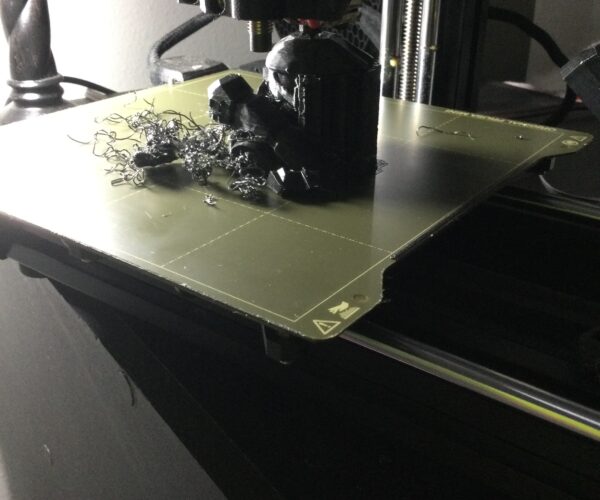

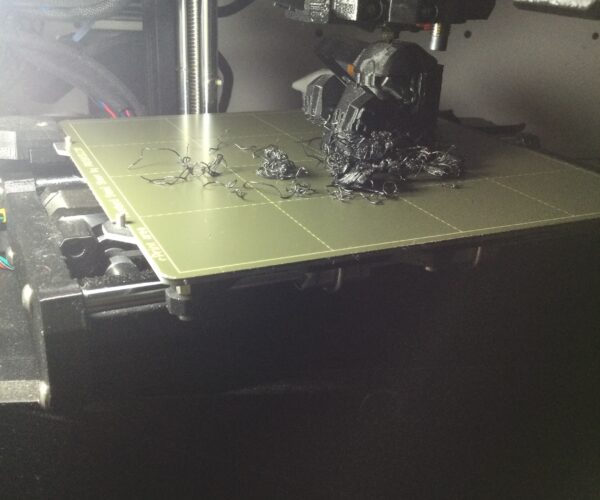

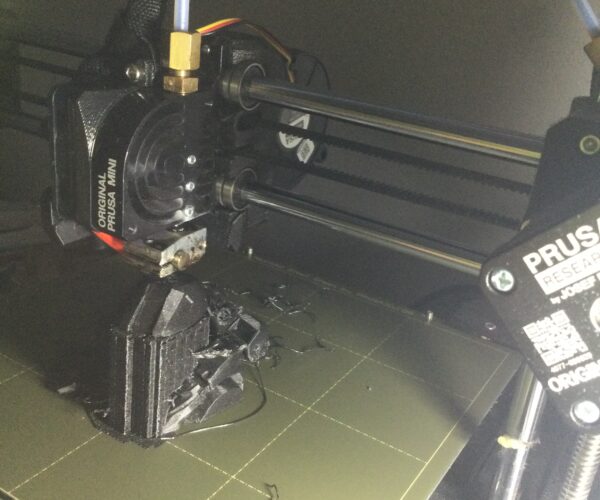

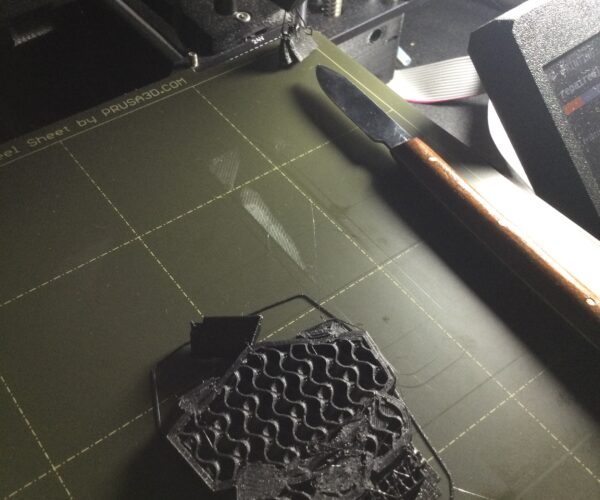

I have printed the halo bust which is a tricky print and it seems that the rear small pieces start to warp around the edges around the 5th layer and eventually the nozzle runs into the lifted edges and rips them off the plate as I’ve pictured. The one in the corner under the nozzle actually got stuck to the nozzle after it separated from the bed . I will print the mlk bust overnight to report in the morning the higher temps seems to make the print appear a bit smoother though I will post pics in the morning hopefully the supports and prints turn out good.

RE: I can’t figure out one of my Prusa Mini issues

So I was able to get a good print this morning of the mlk bust super scaled down so I do have high hopes with just increasing the temperature by 10 degrees. But I am still not getting hood prints on the halo wings. It seems it fails when the wings are getting close to the body. I’m not sure what’s happening maybe there nozzle is not traveling straight across so it’s bumping into the print? I’m not sure I have some pics below. I am going to print a larger mlk to see if I have success with him

RE: I can’t figure out one of my Prusa Mini issues

I want to say hank you to everyone that contributed to this post. I ended up battling these less than consistent issues for over a month until I reached out on this forum and it seems the forum got me going in the right direction but it didn’t provide the consistency I was looking for so I was still on the hunt to get more consistent prints. I ended up upgrading my horned from the stock hot end to an all metal e3d on and I was a little hesitant about installing a part that was not made for the mini but it fixed my issues in the first print. I am able to print the halo wings first try now and it looks great. I did increase the temperature from earlier in this thread but I am getting slight stringing now with the new hot end so I may go back down to the normal 215 temps. The only draw back that I see from this upgrade is that it pushes the nozzle forward slightly so the initial purge line doesn’t stay on the bed but other than that it worked flawlessly and this was my first time having my hands on an e3d hot end so I definitely recommend. If there are any additional questions anybody has please reach out.