How does temp. influence mechanical property of Prusament PC Carbon?

Hi all

I started using the Prusament PC Blend Carbon on my Mini. I pretty impressed how easy it is to print, how rigid the parts are and how nice looking matte surfaces you can get.

I just used the default profile coming with PrusaSlicer, with the nozzle temp of 280C. I also tried to go to the max (290C), but there is no obvious visual difference to the default temp.

I'm wondering, if the mechanical properties of the parts can be improved using a higher temperature. Does someone have experience with this?

RE: How does temp. influence mechanical property of Prusament PC Carbon?

In theory a high temp could give better bonding to the previous layer but Prusa may already have the optimum temp. Certainly interlayer adhesion is the weakest link in any model and I would like to see any tests to improve interlayer adhesion.

Im using Prusament PCCF for structural parts and make sure the stresses impact minimally on the interlayer.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE:

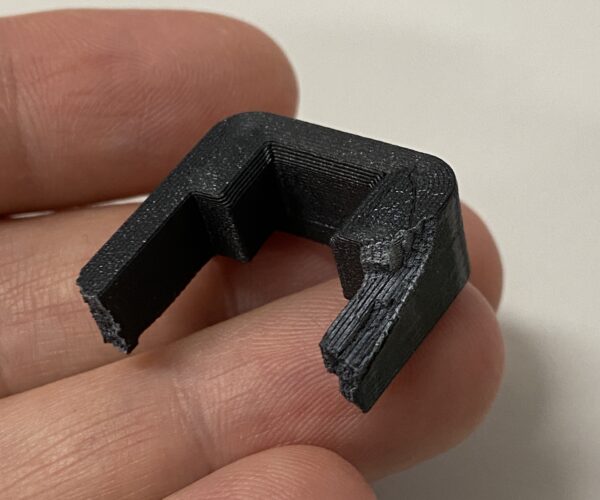

Yes, agree! When printing parts, i sometimes struggling with bad layer adhesion mainly with ASA. PETG has a good layer adhesion, but this PCCF is even better i would say. It's also visible when it brakes (and it needed quiet amount of force to do...). This part was printed with default settings... Pretty cool, this will become my favorite filament for rigid parts i think.

RE: How does temp. influence mechanical property of Prusament PC Carbon?

You want tests on filaments then you need to be watching CNC Kitchen on youtube. Steffan is very good and methodical in his testing.

RE: How does temp. influence mechanical property of Prusament PC Carbon?

You want tests on filaments then you need to be watching CNC Kitchen on youtube. Steffan is very good and methodical in his testing.

Yep, i follow him as well. I think he only tested the PC without carbon so far.

RE: How does temp. influence mechanical property of Prusament PC Carbon?

Pretty cool, this will become my favorite filament for rigid parts i think.

Hi @liceo - are you printing in an enclosure? And I'm guessing you're using a hardened nozzle? I'm considering trying PC but not sure what mods I require to get there.

Thanks!

RE: How does temp. influence mechanical property of Prusament PC Carbon?

I'm using a hardened 0.4 nozzle without enclosure and a Bondtech feeder and a bondtech heatbreak. But I think it should be possible to print PCCF with the standard feeder/heatbreak as well. The hardened nozzle is a must, otherwise the brass nozzle will be damaged because of the abrasive carbon.