Flexfill twisted in extruder

I'm a new Prusa Mini user, now on my second 3d printer, the old Tevo Tarantula did only PLA.

After some successful prints with PETG I wanted to try out flex filament, Flexfill 98A in particular that I bought together with my printer.

I got a calibration cube from thingiverse ( https://www.thingiverse.com/thing:2882777) , started Prusaslicer 2.3, loaded the profile for Flexfill 98A and set the printing profile to .2mm speed, flexfill98 and mini+, no manual changes to those.

Everything was fine but almost at the end it felt like there was a clog in the hotend (it wasnt't that in the end). The filament wouldn't go anywhere and in the end I opened up the extruder -> the filament was twisted there and wouldn't move (it was quite hard where it was twisted).

The first time I though that there was just a bad piece in the filament and tried printing the same gcode again and it failed at what likes to me in the exact same place. I guess there is something in the gcode that makes the print go bad, perhaps a too strong extraction that won't allow feeding the filament back to where it was coming from? (I have the filament sensor installed, perhaps it adds a tiny amount of extra drag?)

Should I just manually reduce retraction speed? I thought the profiles for printers and filaments were kind of ready-to-use and should not require further tweaking. Or could it be something else besides retraction? Some tweaking of the extruder?

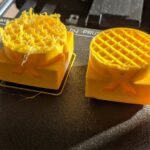

The first image shows the two prints, the first print I already cleaned up a bit with a knife.

RE: Flexfill twisted in extruder

I managed to print a TPU test wedge after cleaning everything up (I just love Flexfill 🙂 ). As I hadn't printed any PLA so far with the new Mini+ I got a benchy and my existing PLA and started printing it out. After a few millimeters of Z there was no filament anymore and once again the filament was quite stuck, this time with PLA.

For some reason in the middle of the print the extruder just won't move filament any more, it is like there is something jamming it. I have opened it, cleaned the visible parts, it spins without filament but when filament is fed to it it just doesn't have the strength to push it through.

The idler shouldn't be too tight, the threads for the tightening screw are just barely in. The bearings are moving freely and I don't see anything that might be jamming it..

(after some more debugging)

The pinion gear in the extruder stepper fell out, my assumption is that the little screw got loose and the pinion was not in the correct place. Now at least PLA printing seems to work again somewhat as expected.

I guess the original issue of Flexfill / TPU printing still applies, perhaps I'll try with "0.2mm quality" and see if that results in a successful print or modify the retract speed for the filament profile.

RE: Flexfill twisted in extruder

It is a pain in the buttocks when that happens. I cut the filament on both ends, turn off the printer, and pull the filament out by hand.

--------------------

Chuck H

3D Printer Review Blog