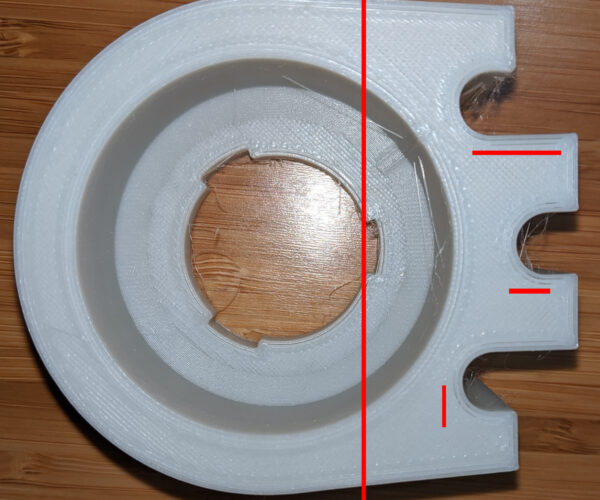

External perimeter separation on eastern side

I could use some help debugging what's going on with this artifact.

For my first 3D printer, out of the box, the MINI printed smoothly with the default equipment and settings and Prusament! So I started to experiment with new equipment and different filament.

I purchased some MH Build series PLA filament, as well as a hardened steel 0.6mm nozzle, but the experience was not as smooth.

Some prints went smooth with those new variables, but the one thing I'm trying to trace down right now is this separation between the object and the external perimeter. Oddly, this only happens to the perimeters on the east facing side (the one closest to the z-axis gears, or x position in the direction of 180). The print settings are kept to the default for the most part .. 0.2mm layer height, 3 perimeters, temps of 215 first layer and 210 other layers, using the default "Original Prusa MINI 0.6 nozzle"

On the first layer, this separation is not present and presents a solid connection between all perimeters and infill. But as this image represents, when I have a flat surface on top, you can see a slight separation on this one eastern side. (Ignore the stringing, that's another challenge I'm iterating through).

Any thoughts on what could be causing this separation on the eastern side of my prints? Or are there some settings I should be tweaking in the PrusaSlicer?

RE: External perimeter separation on eastern side

I do not use the Mini, but this looks like a simple case of a slight underextrusion.

If this were my print, I would probably try increasing the extrusion multiplier in the slicer very slightly.

RE: External perimeter separation on eastern side

Hardened steel nozzles don't have the same thermal properties as brass nozzles, you'll need to raise your hotend temps up by maybe as much as 10 or 15C to mimic results from a brass nozzle. Also as mentioned above tune in your extrusion multiplier.

https://help.prusa3d.com/en/article/extrusion-multiplier-calibration_2257

RE: External perimeter separation on eastern side

Thanks for the suggestions!

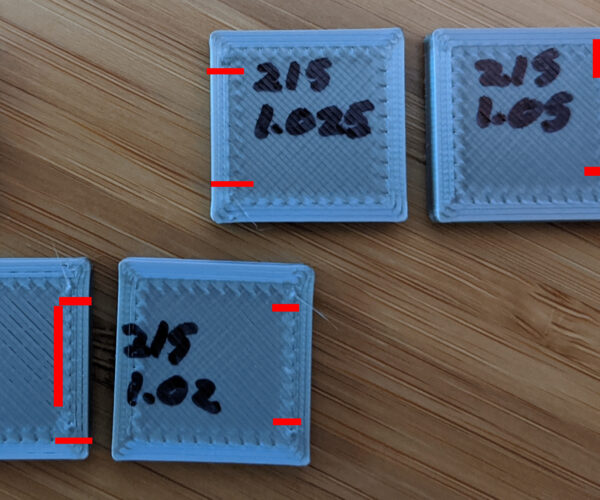

I started a grid search on the extrusion multiplier setting with the temp increased, and could use some help interpreting the results.

I can clearly see visible gaps between layer lines at 1.0 and 1.015. But also at 1.015 I can see some excess material near the perimeters, which continues on through 1.075. Or am I interpreting the imperfections at the corners incorrectly as over-excursion when they could just be blobs (which is contributing to the stringing)?

For stringing, my understanding is I focus on a grid search through the Retraction Settings next. Before heading down that route, it'd be helpful for my learning if someone with more experience than me could chime in at to which extrusion multiplier they'd continue with from the image above.

RE: External perimeter separation on eastern side

Hi, Szelenka. Did you manage to solve the issue? I'm having the same problem with a 0.8 mm nozzle printing some generic PLA with Prusa Slicer default 0.8 mm configuration. My external perimeter on the left (west) side leaves a gap.

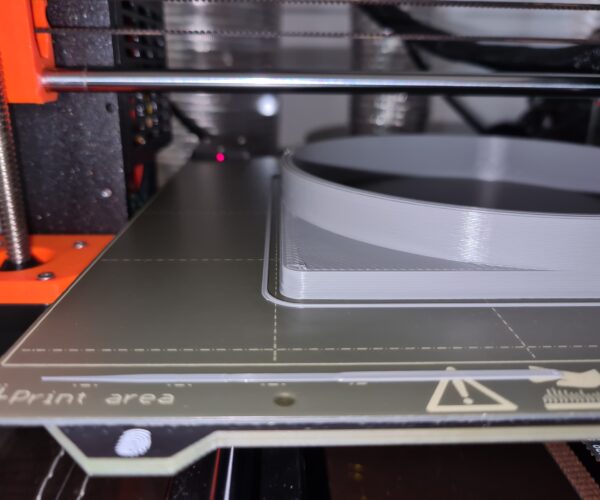

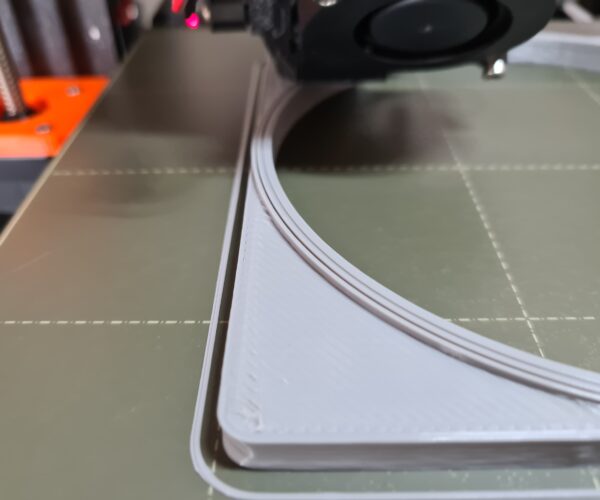

The first image shows a strange shift to the right in the skirt's second layer leftmost edge. It is most noticable right in the corner. All other skirt edges (front, back and right edges) have their first and second layer perfectly aligned.

This second image shows the perimeter gap that only occurs on the leftmost edge as well. Strangely enough, it does not happen on the "inside" of the hollow part.

All other perimeters and edges of the part appear perfect. What could cause this?

RE: External perimeter separation on eastern side

For the steel nozzle, I had to blast it with heat at the beginning. Something like 230-250 for PLA on the first layer or half of the first layer, then decreased it back down to 210-215 for the remainder of printing.

I'm also convinced the filament I was testing with wasn't the best. Switched back to using Prusament and haven't had those types of issues again.

RE: External perimeter separation on eastern side

Hope that still helps someone.

I had the exact same problem. Spent some time tinkering around with flow rate, heat and so on. After i watched the print for quite some time I noticed that my layer started on front right side. Than I noticed that I had an underextrusion after the layer change which (with 2 peremiteres, significantly reduced the inner peremiter). May be something to do with the retraction setting during layer change. What did it for me now was putting a small cube on the front right which is printed first in every layer. The cube suffers from peremiter separtion now and my print is fine.

I have the same behaviour with filament change during print. The first 2 cm are significatly underextruded. So i placed a cube there too and now it‘s fine.