Correct OD, undersized ID

I am having some issues with printing items with nut and bushing press-fits. So I designed a simple cylinder with 25mm OD and 10mm ID. The OD measures very good at 24.98mm, while the ID measures undersized at 9.80mm. How do I correct this? I am a little confused how the OD can be so good while the ID being off this much.

Best Answer by Neophyl:

Quite normal with 3d prints. Holes are usually undersized. Its why you print calibration pieces to see what needs adjusting for proper fit and then design those in.

Of course what works for your printer/filament might not be good for someone else but thats also the norm when downloading and using other people models.

For example for a clean hole for a M3 screw I design in a 3.2mm hole. If I want to have to screw its in slightly so its tight then a 3.1mm will be enough. If I really want the threads to bite into the plastic then 3mm is ok. Not that I usually have screws into plastic anyway, thats what threaded inserts and nut pockets are for naturally. The other common thing is you ream them out to size with a drill bit after printing if its for screws.

Some slicers have adjustment settings you can enter but thats trusting an algorithm to figure out which are holes and which are features. Better to account for it in your design if needed as it can be hit or miss.

RE: Correct OD, undersized ID

Quite normal with 3d prints. Holes are usually undersized. Its why you print calibration pieces to see what needs adjusting for proper fit and then design those in.

Of course what works for your printer/filament might not be good for someone else but thats also the norm when downloading and using other people models.

For example for a clean hole for a M3 screw I design in a 3.2mm hole. If I want to have to screw its in slightly so its tight then a 3.1mm will be enough. If I really want the threads to bite into the plastic then 3mm is ok. Not that I usually have screws into plastic anyway, thats what threaded inserts and nut pockets are for naturally. The other common thing is you ream them out to size with a drill bit after printing if its for screws.

Some slicers have adjustment settings you can enter but thats trusting an algorithm to figure out which are holes and which are features. Better to account for it in your design if needed as it can be hit or miss.

RE: Correct OD, undersized ID

Thanks for the response. I wanted to make sure it wasn't a setting issue.

I understand needing to adjust fit per printer, but this seems like a software change that could be made. The software should be able to match the model. It seems strange to model a different dim to get the final dim you want when your printer is precisely calibrated.

RE: Correct OD, undersized ID

@neophyl speaks true, but I can elaborate.

When your printer prints a 3d model it's placing the line immediately in the middle of the nozzle. Your nozzle extrudes filament with a certain thickness, for most printers it's 0.4mm. This means that you're going to have approximately 0.2mm on either side of the line, I say approximately because there's some variation based on things like feed rate and how well your filament holds to 1.75mm.

When Neophyl says a 3mm hole should be designed 3.2mm that's taking into account for extruded filament thickness.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Correct OD, undersized ID

Again that's not actually true Bob. The slicer takes the extrusion width into account and estimates where the extrusion is going to be pushed out to and moves the actual printing line inwards. If it didn't then all holes printed with 0.4mm extrusion width would be 0.4mm small, and they aren't. However it doesn't do a perfect job on that and any over extrusion and its wider than the slicer estimate. The other thing about holes and curves in general is that they aren't perfectly circular, being made up of short straight segments. These leads to 'cutting the corners' on travel paths.

On the outside the 'points' or joins of the line segments are worked out to be on the line (taking the extrusion width into account). This means the max is your outer diameter but the segments are fractionally under. When you measure though its accurate as you are measuring the widest points. When it does the same on an interior hole though then it has the effect on crossing of being fractionally smaller. Also any over extrusion has no where to go except into the hole making it smaller still. This all adds up to slightly reduce an interior hole.

Its thew nature of the medium so like any production process you have to take it into account when designing. Same way you take part shrinkage when casting in metal. In fact as most of the 3d plastics we print with do shrink at least slightly (some more than others) this too can have an impact on this. Try printing with ABS and you have to worry about it alot more.

As I mentioned Mark, some slicers do have the ability to add an adjustment for holes and even part shrinkage. PS however does not. Something like Super Slicer does. However as I also mentioned its hit and miss and can be quite complicated. So far we have been talking about round holes, well there are square holes, irregular shaped ones etc. Lots of variables. You can let the slicer decide for you if it supports that but at the end of the day human judgement is usually much better than a program.

Unless you spend millions of dollars and loads of time on it which some of the commercial software does. Usually at the design stage. At the local foundry their cad software does precisely that as it can work out from the shape and the material etc exactly how much to change the desired shape to take shrinkage into account. Not exactly a slicer but you get the point that its usually done in the design stage for the medium you are using.

RE: Correct OD, undersized ID

I'm sorry Neophyl, but you're the one who's wrong here and your 3mm to 3.2mm proves it. A 0.4mm nozzle means you'll have 0.2mm on either side of the line. Divide 0.4mm by 2 (a line has 2 sides) and you get 0.2mm which is the exact amount by which you adjust your holes. Expecting a slicer to decide which side of the line to move by 0.4 is asking it to read minds. Many makers like Thomas Sanladerer, Chuck Helleybuyck of CHEP and Angus Deveson of Makers Muse have videos where they talk about this issue.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE:

Unfortunately I am not. Wrong that is.

I'm afraid your math is wrong too. First of all a 0.4mm nozzle has a default extrusion width of 0.45 in a standard prusa profile. So if the line was exactly in the middle then it would make the hole be 0.225 smaller. Except the other thing you forget is you have to reduce it all the way around the 'hole'. So it would 0.225 on one side PLUS another 0.225 on the other side. Mmm by my calculation that makes 0.45, funnily enough the extrusion width. So if I wanted a 3mm hole I would need to model in one 3.45mm in diameter. I don't have to do that, 3.2 is quite sufficient. My filament diameter is also set to match the filament and my steps per mm are correct too. When I print a single perimeter it is bang on 0.45. I spent quite some time dialing in my setup. So that factor doesn't muddy the waters.

It doesn't have to 'read minds' as you put it. It knows which are external perimeters. They are even colour coded on the preview. Its simple math and code.

If you really really believe that PS works as you describe then I urge you to go open an issue on Github.

The url is https://github.com/prusa3d/PrusaSlicer/issues in case you werent aware.

It will closed as invalid though. As it doesn't work like that. Or you could ask several of the other knowledgeable people here or even go check out the code for yourself.

It's great that you want to help people but please please check your facts first.

RE: Correct OD, undersized ID

You are wrong. I'll let Chuck from CHEP explain it.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Correct OD, undersized ID

I've already seen it. Same as I'm quite familiar with all the youtube producers you list. I think Ive seen most of Tom's and CNC kitchens and Angus is always fun. It's just my own experience differs and I don't automatically believe everything on the internet.

Again I invite you to open an issue on github for this serious bug in the software.

That Youtube video very carefully explains exactly how not to do it. Avoid.

He correctly measures and calculates the calibration required but then fails to incorporate it in his design ... Tolerances are part of the design process, ideally as a variable that can be reset according to process. They are not something to add in as an afterthought at production time.

@neophyl is right.

Cheerio,

RE: Correct OD, undersized ID

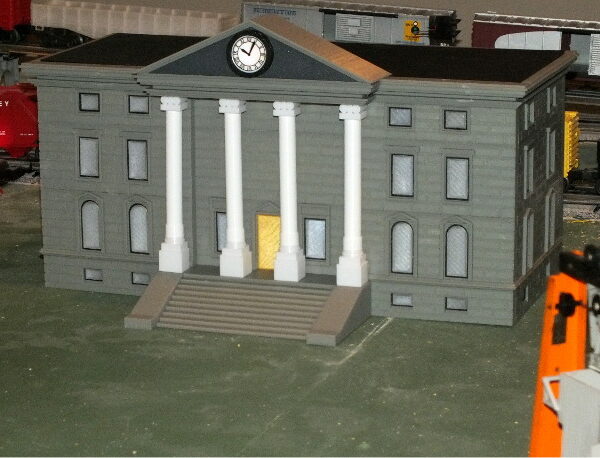

Over the past few years I've done a lot of O-scale model railroad buildings and facades having snap-in window and door frames and snap-in panes in the frames. I did some of these at our local 'makerspace' before I got my own printer, but most on my own printer(s).

My goal is to have everything press-fit with enough friction to stay without glue.

I'll usually start with .1mm of gap when drafting, but I've found over and over that test prints, with iterative trial-and-error tweaking, are necessary.

There are so many variables, some of them not as obvious as others.