CoPET tearing on seams

Hello!

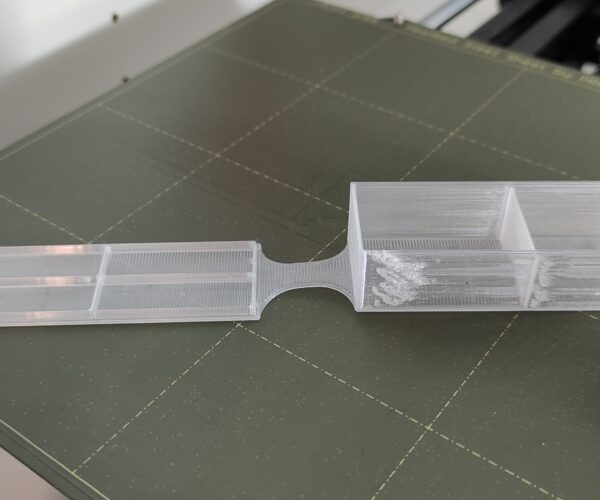

I've been trying this new coPET plastic from a local brand and it prints fine on my MINI+ with manufacturer-specified temperature ranges (230 to 240C) and cooling (enabled). It mostly works fine with very minor stringing and small test pieces (cubes and coins) work without any issues, but I have this specific artifact appearing on print seams that causes major tearing. I've tried to play around with retraction (slower/faster) and wiping (on/off), but nothing really helps, artifacts just look a bit different.

I slice it with a default 0.2mm speed profile for MINI+ in PrusaSlicer. I should also note that I do not have this problem with Prusa original PETG filament or with PLA from the same brand.

The model here is a remix of this cute screw box.

So the questions is: what should I attempt to troubleshoot this?

RE: CoPET tearing on seams

[...] I slice it with a default 0.2mm speed profile for MINI+ in PrusaSlicer. I should also note that I do not have this problem with Prusa original PETG filament or with PLA from the same brand. [...] So the questions is: what should I attempt to troubleshoot this?

For most any print quality issue, the first test I'd try is simply slowing down. You mentioned you're using a SPEED profile. Try dialing speed back 50% using the front knob during a print and see if that helps. if quality improves, you know there are settings you can try in your slicer. Unless you have a known-good filament profile, greatly reducing the Max volumetric speed (MVS) setting is a simple way to cap speeds in your slicer with a single setting. That sets an upper limit on the flow of filament, reducing speeds if and only when necessary. Try setting MVS to 1 and see if the print succeeds. If so, bump it up 2-3 mm^3/s to figure out your upper limit. As things start to look "mostly good", you can further refine the profile.

I've got some notes here on calibrating filament presets using PrusaSlicerthat might be useful to you.

Save your current 3MF project file, zip it up, and attach it to a reply here so we can see your part & settings and give better recommendations.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: CoPET tearing on seams

@bobstro

Thank you! I've calculated MVS (set to 4.9mm3/s) from recommended max linear extrusion speed (40-60 mm/s) and assumed it should be good, but I'm going to try to slow it down further. I'll add a 3mf if this will not help.

RE: CoPET tearing on seams

Are you getting the tearing on both front & back? Does it tear near the start or end of extrusions? (I assume the start.) You might want to create a test printer profile with reduced acceleration and jerk values for this filament. Slowing down should improve the issue, but it may be the rate of acceleration that's the underlying problem. It might be worth drying the spool out before you go changing too much settings-wise.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: CoPET tearing on seams

@bobstro

An update! I've tried 0.2mm quality profile with lowered speeds. Artifacts became less horrible, but still are very much apparent.

Slicer file is here: Small Part Box v10

> Are you getting the tearing on both front & back?

Tearing appears to be in the wipe zone after every major seam. Disabling wiping or reducing it's distance leads to a clump up around the seam.

> Does it tear near the start or end of extrusions?

I'm not sure, but I think it's in the end or after (in case of wiping).

My next step is try to reduce acceleration and to dry the filament (though I don't think it's about moisture, as the artifacts started to appear just after breaking the seal and other regions do not look like they have bubbling issues or local under/overextrusion/