RE: Beginner: Consistent problems with Filamentum Crystal Clear PLA on Prusa Mini

Hello ... I also tried printing Fillamentum PLA Crystal Clear Iceland Blue on my MINI, and ran into the same issues mentioned above ... lucky me I just recently got a MK3S+ ... so I tried it on it, and also had same issues ... then I read discohomer's comments above, and looked the the Fillamentum site, and Fillamentum's range for temp is 210 - 230C ... so I tried 230C, but my extruder kept clicking ... so I used the Speed setting and brought it down to 70% ...

I print the first layer at 215C @ 69% Speed, and the layers above that at 230C @ 69% Speed ... and so far that is giving me very good prints, and no clicking extruder.

I will try these settings on my MINI next and see if they hold up ... I am hopeful ...

Iceland Blue is a beautiful filament ... and what is kinda funny is when I first got it, I printed a Makers Muse coin, a Benchy, and the icicles from faberdasher on Thingiverse ( thing:196653 ) ... and they all printed perfectly ... so I satisfied my curiosity about Iceland Blue, and continued on with my then current project which required a different filament

Now I am coming back to use Iceland Blue for more stuff and found it a different experience from when I first got it ... hopefully we can get the settings for Iceland Blue figured out.

Oh ... and Hobby Hoarder used faberdasher icicles in a project of his that caught my attention too .... its called "3D printed LED icicle Christmas decoration" in Prusa Prints

More to come ....

RE: Beginner: Consistent problems with Filamentum Crystal Clear PLA on Prusa Mini

Hello

I found success in printing Fillamentum PLA Crystal Clear Iceland Blue by using 230C on first layer, and all layers above, AND by setting the Speed setting at 69%, AND no extruder clicking !

These settings worked on my MINI, and on my MK3S+

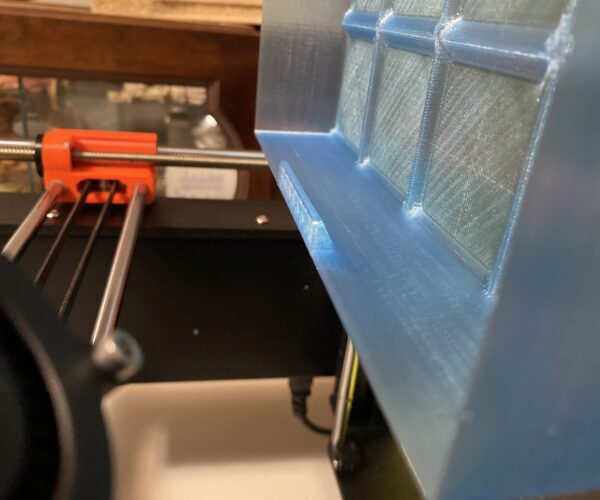

I was printing Alexandre Chappel's drawer organization grids and boxs, on my MK3S+, from his site www.alch.shop

His boxes include a cantilevered label "shelf" on the inside of the box, which I was having difficulty printing with the Iceland Blue (but not other filaments) ... once I used 230C at 69% Speed, those printed beautifully.

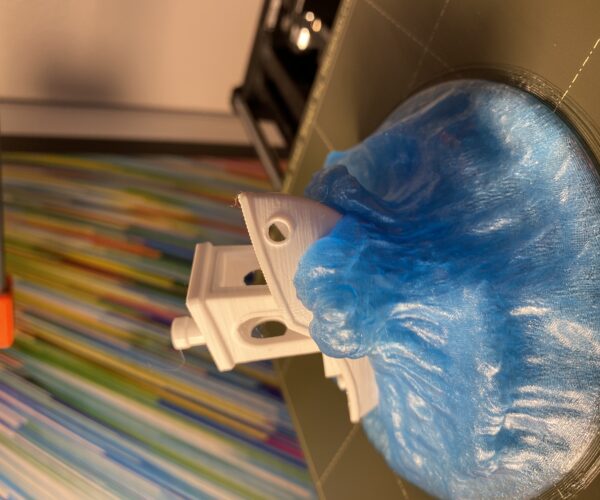

On my MINI I printed the Benchy at Sea/Wave Display by nexnox (Thingiverse thing 30024)

It printed beautifully at 230C at 69% Speed, with no extruder clicking !

I really like the Fillamentum Crystal Clear series (5 colors, 1 clear), and I think I have found the settings to print the Iceland Blue ... a larger time investment, but good prints and no clicking !

Hope your experiences are awesome !

RE: Beginner: Consistent problems with Filamentum Crystal Clear PLA on Prusa Mini

Thanks @prusatv for sharing your settings. This is super helpful. And also for sharing your print pictures.

RE: Beginner: Consistent problems with Filamentum Crystal Clear PLA on Prusa Mini

Hi all!

I have the similar (or the same) issue on Prusa i3 MK3S (which is direct drive, by the way), with the same Filamentum PLA Extrafill Crystal Clear Iceland Blue.

Sometimes in the beginning, sometimes in the middle of print filament stops extruding, and extruder stepper does back steps (easy to see with a visualizer) with a clicking sound. I'm not sure how filament softening above the heatbreak can cause this, my noob's hypothesis is that part of the filament in the nozzle enters some unusual high-viscosity state, so it clogs the nozzle, so when extruder gears push it, filament springs back causing gears to step back, which is that clicking sound.

Usually filament unload/load works as a temporary workaround. But if the problem occurs in the middle of a print, and I'm not there to help, the print is failed.

I've tried lowering the temperature and decreasing print speed. So far this maybe lowered the rate of the issue, but doesn't make it gone completely. I will also try:

- Upgrading the firmware. I have 3.9.1 now, and 3.9.3 is currently available.

- Leaving the print chamber open. I have a hand-made one, mostly to save printer from dust when not in use, but it keeps the temperature as well.

- Other filament. I also have Filamentum PLA Extrafill Crystal Clear (just translucent white one), yet unpacked. Different types of filament didn't cause any similar issues so far, and the blue one is my first from Filamentum.

- More printing 🙂 In hope that I'll notice some other correlations.

On the photo attached I showed filament tail I cut after issue (and unloading/loading). What I can see there (not sure is photo is good enough for that, sorry):

- Gear traces look completely intact, no sign of gears sliding over the filament.

- While the filament itself (and resulting prints) look glossy, a little of plastic at very tip (part which was right in the nozzle) look matt.

Later I'll try comparing this with filament tail without the issue, but maybe this matt-looking will tell us something?

RE: Beginner: Consistent problems with Filamentum Crystal Clear PLA on Prusa Mini

I've had the same issues with the Fillamentum Extrafill filament. I've tested lots of different things with it now and have come to a solution that works for me.

This filament seems to be struggling with any layer heights lower than 0.2mm. When printing with a 0.4mm nozzle I can print at normal speeds at 0.2mm layer height. As soon as I go down to 0.15mm layer height with 0.4mm nozzle, I need to lower the printing speed drastically( <25-30mm/s ) and maybe even adjust the temp to 220-230C. The same goes for printing with 0.3mm nozzle, I usually print at 0.15mm layer height then, which requires me to print with very low printing speeds and higher temps.

The settings I can use with the 0.4mm nozzle at 0.2mm layer height is; 210C and up to 50mm/s print speed.

This also seem to only apply to the "Extrafill" category from Fillamentum. There are probably some particles in this filament that needs a certain amount of space to flow freely.

The machine I've been using for this is a Zmorph VX, so these settings may vary on different machines. But I hope this can be of some help.

RE: Beginner: Consistent problems with Filamentum Crystal Clear PLA on Prusa Mini

gets yourself a temperature tower pattern that is already set up for your model. I have had many successful prints with Filamentum extrafill and with super clear. it's a lesson for _you_, not a lesson for filamentum. Read the box. The temperature ranges are different.

RE: Beginner: Consistent problems with Filamentum Crystal Clear PLA on Prusa Mini

Thank you for posting. I had/have the same issue with the pla I bought with printer "Fillamentum PLA Extrafill Crystal Clear Iceland Blue". I switched filament it when I heard the clicks to troubleshoot, and the regular pla I switched to stuck. Cold pull and teardown to clean and I got it working. I finally got the mini last week and it's been a nightmare, at least I know clear is not for noobs but I did learn a lot. I choose PURSA for a lot of reasons and community was top of the list.

RE: Beginner: Consistent problems with Filamentum Crystal Clear PLA on Prusa Mini

@rjhunter

This filament is not for beginners. It is tough to get to print. The first thing to remember is to check the temperature settings as @dan-rogers pointed out above.

--------------------

Chuck H

3D Printer Review Blog

RE: Beginner: Consistent problems with Filamentum Crystal Clear PLA on Prusa Mini

Hi Discohomer, thanks for the tip. I was experiencing some random issues with this filament: sometimes the prints would be Ok but most times they were horrible; after three repeated failures today, I increased the temperature to 225 and the next print was perfect. Not only the clicking noise went away but also the stringy oozing filament left on the bed perhaps from being cooled down too quickly. After all, the suggested temperature stated on the box is 210-230.

Thanks all for sharing your experiences!

Now it's fun again

WOW - you totally saved me here. I tried all kinds of things, but sure enough - as soon as I bumped up the heat, things stopped clicking. Also, I've been printing at 100% fill density on this filament. Thanks!

I think higher temp makes more sense on a Mini

Dan's advice might not exactly apply to the Mini, since the heat isn't anywhere near the extruder gears. So if the mini is getting backed up and causing the gears to grind away and jam or break the filament, then seems more likely that increasing the temp will help here. I also just think the Crystal Clear has a smoother/glassier/more brittle feel to it than stuff like Prusament, which is probable a big source of the issue.