Adjustments to PETG settings (heat tower attached)

Hello everyone,

I happily own a MK3S since this week. I have 1year experience from my creality cr10s regarding PLA/PETG.

Could you please advise me on how to fine tune the standard Generic PETG Settings?

I used the original Prusa Temp Tower for PETG (220°C - 260°C). Belt Status is X 254, Y 283 (which, when machine is warm, was 274 yesterday). I use the powder coated steel plate. No Enclosure. Filament is kind of fresh (only a few days unpacked/repacked).

My first print (small cube) came out perfectly nice. I wanted to investigate on the perfect heat tower temp to further improve future prints and the result isnt that great.

My examination:

Strining

Especially on the outside corners with overhang it tends to warp upwards.

Some blobs accure (due to stringing?).

Bridging is not good.

On layer change there is some very rough/fuzzy seam on the 45° edge (hardly visible in the pictures, sorry).

last layer surface is nice and smooth but maybe underextruded? The gaps to the perimeter walls seems to lack a little material.

There is no clear indication on what temp is best. What would you chose?

Pictures are in google drive:

https://drive.google.com/drive/folders/1ha7BmNmqxWf4CT_-ZXn8UBIBjIN2G_Sh?usp=sharing

Thank you guys a lot!

RE: Adjustments to PETG settings (heat tower attached)

The pictures on Google Drive, are password Protected

could you please try attaching them here

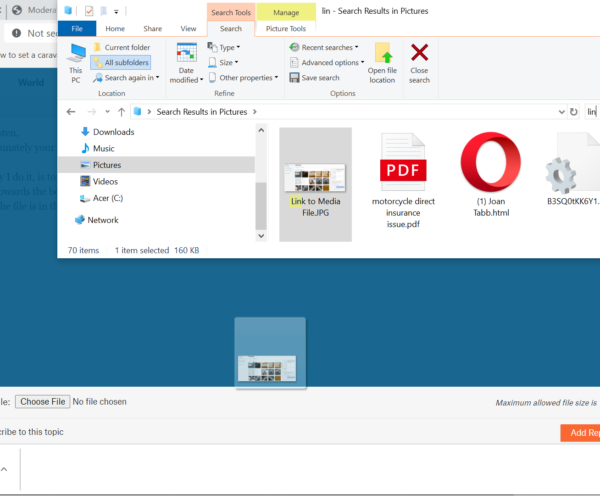

Place your cursor where you want the file to be inserted, then...

If you open a small file manager window over the forum text input window, you can drag a file to the bottom of the text input window, when the text input window changes to another colour, Blue in my case, you can drop the file

then another window like this should open, click on 'Link to: Media file' (you should only need to do this once then the forum should remember the setting)

then click

Insert into post and the picture should be inserted into the post

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Adjustments to PETG settings (heat tower attached)

@joantabb

Thanks for the hint, I totally missed to check the box for that. Link is now viewable.

RE: Adjustments to PETG settings (heat tower attached)

@schwabstrasse

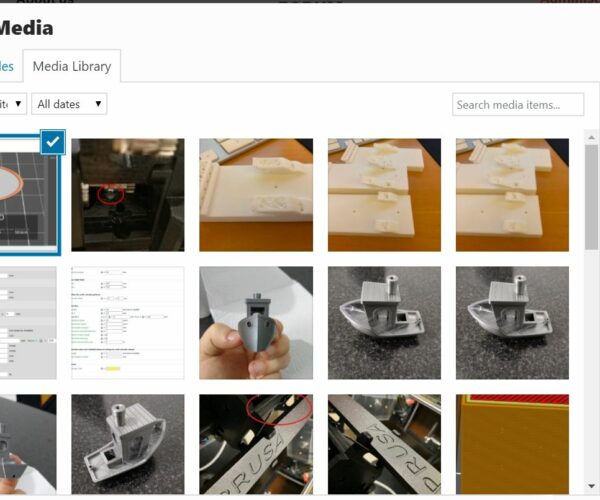

It looks like the bottom layers have lease stringing... I can't see the tips of the slopes.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Adjustments to PETG settings (heat tower attached)

This is a Mini forum. If you really have a MK3S you will probably get more help in that forum. I only have a Mini, so any advice I have might not be the same for the MK3S. The middle one looks the best, but I agree none look great. On the Mini, there really is not one best temperature. It is different for different objects and filaments. I have found that hotter results in a better surface finish but more stringing. Cooler has less stringing but more surface finish issues.

I highly suggest you dry your filament, even new filament. On the Mini, that seems to be very important. Again, I don't know about the MK3S. The Mini uses a Bowden extruder and it acts differently than the direct extruder on the MK3S, but it seems that dry filament is always better.

Regards,

Mark