within 30 layer flow is reduced

HI,

Within 30 layer flow is reduced to half and then no flow. I've been through the whole filament pathway, from extruder to the nozzle.

I think it's a small gap between the end of the Hotend PTFE tube and the nozzle reservoir. The filament end expands and this prevents it from move forward. But why ?

Ive tried new Hotend PTFE tubes and really cleaning out the nozzle with no luck. Everything I've tried makes no difference. The print fails with in 30 layers or so.

thanks for any help

RE: within 30 layer flow is reduced

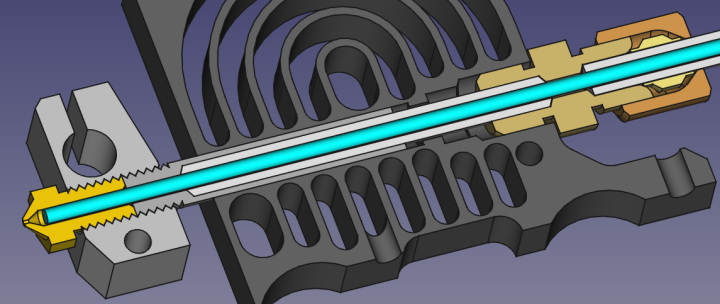

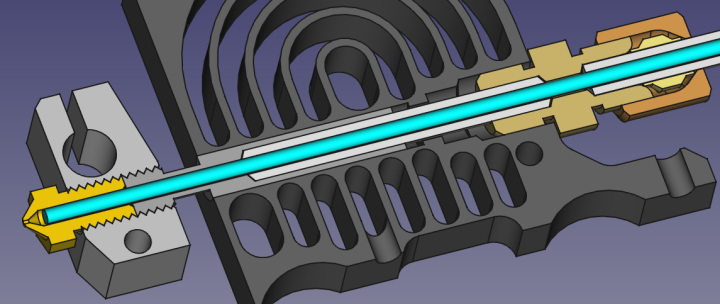

At the end of PTFE tube (between chamfer and heatbreak) should be NO gap:

In that region (where PTFE tube ends) temperatures are "critical": that is, colder than heater block, but still hot enough to soften the filament. That softened filament slowly deposits on heatbreak wall and cools down (because it's close to heatsink)... and process continues until we actually notice clog (reduced extrusion in case of partial clog).

The only solution is, to make sure that PTFE tube has proper length (~43.5mm) and that nice & clean chamfer is made. Of course, the whole hotend must be assembled properly afterward.

Also keep in mind, that PTFE might shrink a little over the time of use (because high temperatures) and so there will be gap again. That's very apparent if some higher temperature filament is being used (PETG, for example).

And that's the main reason why so many decide for Bondtech heatbreak. If you take a look on differences, you'll notice why that's such an important improvement:

[Mini+] [MK3S+BEAR]

RE: within 30 layer flow is reduced

BogdanH,

Thanks for taking the time to constructing a wonderful reply. Yes that was my first thought and something fully understand. Sadly I've done that twice with the same out come. On that note, Prusa should/could machine the parts to eliminate the chance of miss adjustment. Maybe a factory reset and flash the original FW and Slicer it came with. I used it 2 years with few issues. I never touched the hotend and one day it just started doing this. Maybe thats all you get out of the mini 2 years and it's toast.

RE: within 30 layer flow is reduced

I never touched the hotend and one day it just started doing this. Maybe thats all you get out of the mini 2 years and it's toast.

I don't have Mini for that long, but it's to be expected that some parts will worn out over the time (PTFE, nozzle, print sheet, bearings,..) and by replacing what's needed, printer will print as new again. It's still cheaper to service the printer than buying the new one -which will need the service too.

Just sharing my thoughts...

[Mini+] [MK3S+BEAR]

RE: within 30 layer flow is reduced

Yes I love Prusa, however I ordered a new nozzle and shipping to the states was $15us so for one nozzle it was $25us, ouch

RE: within 30 layer flow is reduced

I got a complete print by increasing the nozzle temp to 235 and the Flow to 110 for Prusa black PLA. Even-though I've cleaned and adjusted the extruder mechanism I wander if that's it. As it's printing I gently hold the filament between two fingers where it is drawn into the tube before the extruder to see if it is pulling filament in. Yes it is with the settings 235 and the Flow to 110. Q.)So if the filament gear was failing before the increased flow then I wouldn't it slip more at a faster rate? I also wonder if the thermistor is sending the wrong value? Q.) dose the filament sensor also help calculate flow?