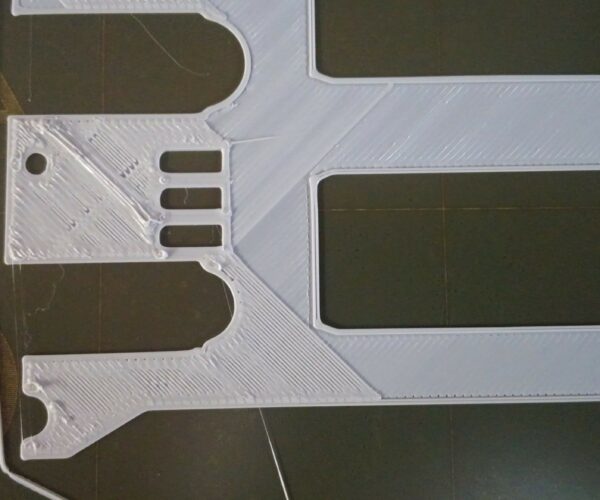

Under/Over extrusion issues

Mini seems to have under/over extrusion issues.

It *seems* to be fine on the first layer (nice and slow), and then these random under/over extrusion issues start developing. You could sell me on extruder slip/grind, except that won't cause over extrusion.

Thoughts?

RE: Under/Over extrusion issues

Check the mechanics, grub screws are tight. Your extrusion is very uneven.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Under/Over extrusion issues

I've tightened the extruder tension to almost completely tight. I can push/pull on the filament as its printing with no discernible effect.

RE: Under/Over extrusion issues

Latest development: my extruder is clicking.

RE: Under/Over extrusion issues

I replaced the bowden tube after noticing tension through it (and its compression sleeves) was kind of high. I though maybe not only were the zip ties too tight, the compression nuts were over-tightened. I was correct.

Fixed all extrusion issues, including clicking on the extruder. Obviously, there was binding going on. There is still a slight amount of under-extrusion, but its uniform, so I'm sure its just a flow rate adjustment for the PLA filament I run.

RE: Under/Over extrusion issues

Did you solve this? I am having similar issues. After fixing the Bowden tube compression fitting issue I am now having under extrusion issues after the first layer. First issue was that I couldn't even push filament through the PTFE tube because the compression fittings were too tight from the factory. I resolved that. Then after calibrating and trying to print I had some under extrusion. I thought maybe some debris got stuck in the nozzle after fixing the Bowden tube so I removed and cleared the nozzle. Not the case. The nozzle is clear, I've checked the compression on the extruder idler to make sure it's properly grabbing the filament, but the printer is under extruding after the first layer.

RE: Under/Over extrusion issues

@tyson-l2

I just got my mini yesterday and had the same under extrusion issues. Reseating the PTFE tube in the hot end seems to have solved the issue for me, although getting all the extra filament that had leaked around it out was extremely fun.

RE: Under/Over extrusion issues

My Mini went back to Prusa for warranty work, but due to 1st layer issues, not extrusion issues. Replacing the bowden tube fixed the extrusion issues for me.

RE: Under/Over extrusion issues

I'm having the underextrusion issue on my Mini. I have updated the firmware, closed the gap between the nozzle and the inner tube, eased the compression fittings, all to no avail. I get to the end of the first layer or sometimes into the second layer and the extruder starts clicking and filament effectively stops feeding. I'm running out of ideas and frankly patience. Anyone know something else I can try?

RE: Under/Over extrusion issues

If the extruder starts clicking, there is too much back pressure.

Thoughts on that:

- Nozzle thermister error; reading too hot (nozzle actually colder)

- clogged/partially clogged nozzle

- issues with the PTFE inside the hot end

- if the PTFE compression fittings were tightened too tight an squeezed the PTFE too small

RE: Under/Over extrusion issues

@rat_patrol

Thanks for responding. Back pressure is all it can be so today I have reseated the ptfe tube in the hot end, cleared the nozzle, cleared both bowden tubes and physically checked that filament passes easily, disassembled extruder and brushed out the little bit of plastic dust. Same result. I think the temp sensors are fine because load and purge are easy and mostly the first layer is great, then it’s not.

I remember reading in the notes for the firmware update that speed was slowed to help with this but it’s not helping me. I’m baffled.