Terrible print quality all of sudden

I am printing for a few months with prusaments on MINI+, sliced with Prusa slicer mostly with default profiles. Lately, my printing went haywire and even wear dreadlocks now. First some stringiness, each print getting slowly worse, then those small dreadlocks appeared and yesterday I made a print which ended up pretty much unusable (carve those painter's pyramids from wood would be probably faster than remove all this mess). Pics:

This one is PLA with 0.4 nozzle a few days old, right from the center of the picture is the seam but there are also some of those dreadlocks, and right from the center there is a whole row of them. They were easy to remove, probably because it is PLA. Now this:

I made this yesterday, it's PETG with 0.8 nozzle and reality is even much worse than it seams from this picture. Dreadlocks and strings are everywhere, there are even fluffs of very fine strings inside each pyramid, surface is very rough, the quality is so bad it hardly serves it's purpose. I'm not doing much alteration or tunning, I just regularly swap smooth and textured plate (having saved live-z value in setup), change nozzles, doing cold pulls from time to time...a few weeks ago I slightly oiled smooth rods with lube which came with the printer, keeping procedure as described in help. Nothing special.

I saw Stephan from CNC kitchen talking about filament soaking moisture from the air, so I tried to dry it for 8h in the oven (50C) but there is no difference. Just a few weeks ago were my prints great and nothing was changed (intentionally) since. What is all this mess, does anybody know?

working the problem

For me, stringing is hydration or temperature-related. It could also come from not enough retraction. I suspect your problem is not the latter. Do you have a roll fo filament that you had success with in the past?

--------------------

Chuck H

3D Printer Review Blog

details

That's the thing, same filaments, same printer, same settings for months, printing mostly every day. That's why I was suspecting moisture and tried the drying, without success though. Weather is one change of conditions, it's very hot summer here these days and I often run AC in my room, but I do not have enough data to find any correlation here. Also those nozzles, I'm swapping them all the time.

I was hoping those thick brittle protrusions sticking from my prints, which I called dreadlocks, could be some well known symptom but it seems not. Are those just thicker stringing or what..?

conditions change over the time

cwbullet (above) pointed out three most important stringing related reasons. If you didn't change anything in settings (and prints were fine), then we should keep in mind, that some condition do change over the time. For example, PETG does suck moisture and it's hard to judge how much, because there are no indications -"nice weather" doesn't really count 🙂, and so drying it is the first thing one should do.

Next thing is extruder, which has moving parts that can change extrusion characteristics over the time. Maybe you have a bit over-extrusion which causes stringing and so you should check that with extrusion calibration (is a simple process). Those protrusions could be indicator for over-extrusion.

And then, it's also possible that hotend thermistor changed it's characteristics over the time. Means, you maybe now print at a bit higher temperature not even knowing (i.e. sensor says it's 250C, but actual temperature is 255C). Means, try to reduce temp by about 5C.

Retraction... well, I would definitely first try to check extrusion and temperature. Usually we sometimes need to change retraction when we change filament brand. But as you're using the same filament all the time, I see no need to fiddle with retraction all of sudden. Yes, maybe you can get a bit better result by changing retraction.. however by doing that, you didn't find the reason for your problem.

Maybe someone else will come with some more ideas.

[Mini+] [MK3S+BEAR]

Stringing

Something has changed and if you did not change anything, something has changed in the machine, slicer, or environment.

--------------------

Chuck H

3D Printer Review Blog

RE: Terrible print quality all of sudden

Dry it again, you can go a little hotter with PETG, 75C should be OK,

Cheerio,

re

I just regularly swap smooth and textured plate (having saved live-z value in setup), change nozzles ...

.... regular nozzle changing (I guess is done on the same printer) , can do marvelous things...

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

Partial outcome

Bogdan, you mentioned extrusion calibration, is this it? https://www.help.prusa3d.com/en/article/extrusion-multiplier-calibration_2257/ I didn't have much luck finding anything else.

I made a lot of experiments and reading since. First of all, I added some grease to the smooth rods, as the printer was quite noisy lately (since the last greasing I mentioned before, clearly I didn't use enough), now it runs smoothly and quietly like a new, even though I doubt it had any affect on the print quality. Then, because everything pointed to the filament, I pulled out this one:

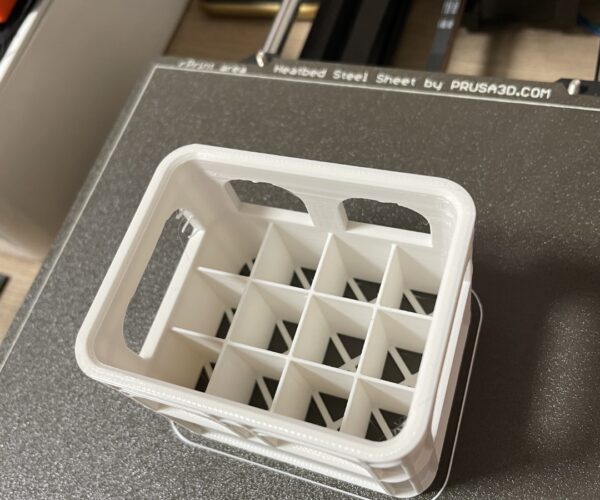

Seemed ok, I tried a complicated shape with a lot of traces:

Nice and shiny, right? Well, there are some strings and even three dreadlocks in the left side window but still it is very fine print. I returned to the spool of black PETG and I immediately noticed bubbling sound during print, strings and worsening quality.

So, my result is this:

1) The black spool has much more moisture (even though they both spend over 8h in the oven together)

2) Some prints (more instances/objects on the bed) means a lot of traversing back and forth which results in tons of paths and higher stringing probability.

3) I finally have to build the proper drybox and will find out if issues like this will ever return.