Sudden top layer problems

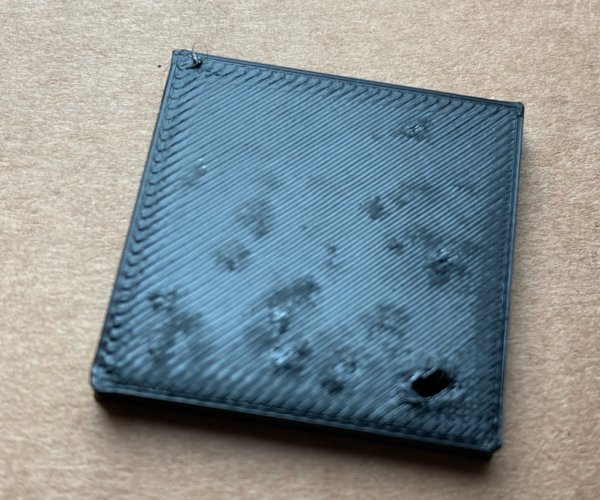

I suddenly started having problems with my top layers that look like this:

This is just a plain 30x30x3mm box on my Prusa Mini with Prusa Slicer (2.4) and with Prusament PETG and the built-in "0.20mm QUALITY" setting with 6 top layers. Sorry for the photo quality, but the biggest hole is all the way through all 6 top layers and into the infill. I can see the top of the bottom (4) solid layers. Some of those other smaller holes are also all the way through. Everything else about this print is fine. It stuck to the bed (stock Prusa textured sheet) perfectly, the sides look fine... This has also happened with some Polymaker ASA, and all the prints I've made in the past few days. This printer has printed many spools worth of filament (PLA, PETG, ASA and even ABS+) with no major issues until now.

Anyone have any ideas or suggestions?

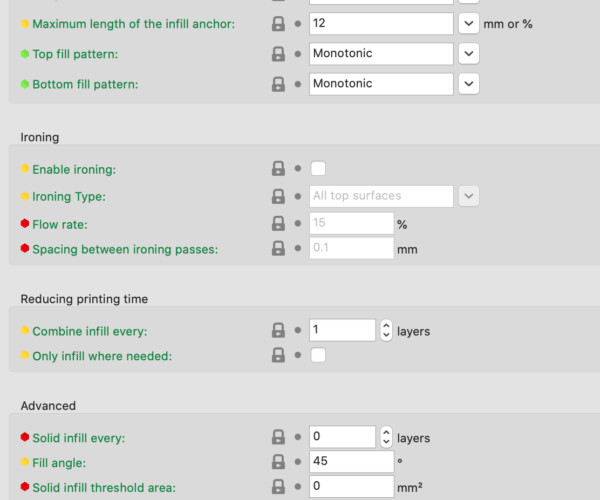

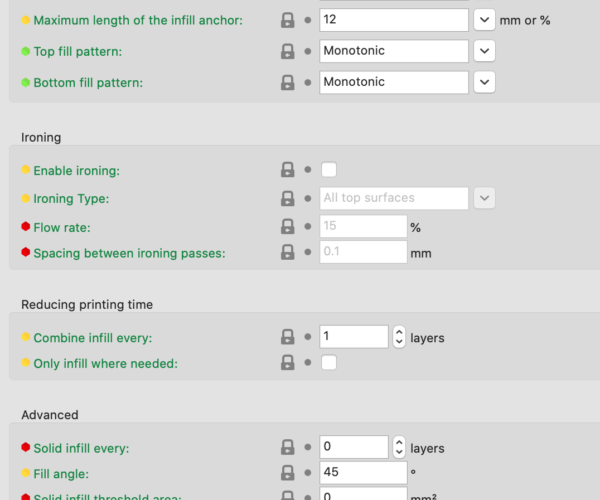

What are your infill settings?

Cheerio,

Hmm.... Try adaptive cubic fill.

Cheerio,

RE: Sudden top layer problems

I tried adaptive cubic infill and it was much worse:

This time I happened to be watching when it got to the first solid layer above the infill and it looked like almost nothing was coming out. I guess the 0.10mm layers make it harder. I'll try again with adaptive and 0.20mm layers.

The blue bit you see there is a piece of my silicone sock which this print managed to destroy with its disgusting mess of a top. I've now removed that too since I don't have any more and that one's ruined.

I have also run the self test just to make sure that thinks everything is fine and it said everything was working. I heard both fans spin up and didn't see anything unusual in the other tests.

RE: Sudden top layer problems

For flat surfaces like that you need more infill %. Otherwise it just sags into the gaps. Adaptive might work as suggested but there are a couple of caveats. One the % set is the highest value, so the % under the surface, for this I'd use 40-60%. Adaptive then works downwards, lowering the infill as it gets further away from the surface being supported. That model doesnt look that high so there might not be enough space for adaptive to, well adapt, and remove infill.

Secondly different infill patterns when set to the same % actually provide different amounts of top coverage. So 15% gyroid is not the same as 15% rectilinear for example. Choose your infill based on what it needs to do. Some give better compression from above, others from the sides. Some are just good for supporting the print of surfaces above them but poor at giving rigidity once printed etc.

The best 2 general purpose ones are gyroid and cubic. Both give similar support for the same amount of material (not the same %, same amount of weight). Gyroid uses lots more gcode as its all curves which shouldnt be a problem on a mini with its 32 bit board but on an old 8bit board it can cause issues with memory on large models. Like so much of 3d printing there is no one size fits all.

Just up the % on whichever one you do choose.

RE: Sudden top layer problems

Thanks for your input @neophyl but I think the real problem here must be something other than slicer settings because *all* my prints were having these problems. Even things I've successfully printed before on this same machine.

Somehow the adaptive print (which was by far the worst) destroying my silicone sock seems to have helped though. After that happened I reprinted the exact same 0.20mm layer print I printed earlier and the surface was much better. So then I printed this plate at 0.10mm layer height which has 2 rectilinear (top 2) at 15% and 20% infill, and 2 gyroid (bottom two) at 15% and 20%. The only one that looks acceptable to me is the rectilinear at 20% (top right), though at least none of them have holes now. So definitely an improvement.

I don't know what it could be that caused this much improvement but I guess I'll take it. I will do some more experimenting to see if I can figure anything further out. If anyone has suggestions as to possible problems with the machine or things I can check, please let me know. I inspected the part cooling fan duct as best I can without taking things apart and did not see any obvious damage. If I can't get to the bottom of this I'll start taking things apart to clean and inspect them.

The latest print described above:

I wasn't paying attention to how thin these are; @neophyl is right, more infill.

Cheerio,

RE: Sudden top layer problems

Thanks for your help.

It wasn't the amount of infill unfortunately since after my sock came off it's now printing acceptably with 0.20mm layers with the same infill it was failing at before. Also I was having this problem on parts of any size. I just switched to testing with these small parts since they're quick to print and I can try different things.

So it's definitely something else wrong that got improved by lack of the sock. But I'll keep trying to figure out what that might be.

RE: Sudden top layer problems

I wonder if it's under extruding a bit.

Mini+ (kit) - Revo Micro | Antler Cooling | WiFi (4.4.0RC1)

RE: Sudden top layer problems

If it was under extruding due to some feed issue then I would have expected the OP to also mention that their walls were not correct too.

Looking at the picture above with 4 rectangles then the top right corner one that has the best top surface also has the highest density of support below the surface. Look how closely the gridded support lines are spaced on each of them. The quality of the flat top surface is directly proportional to the spacing of the infill. Notice how the rectilinear pattern also provides a more dense support than the gyroid at the same infill %.

This was the point I was trying to get across. Flat surfaces like these work better with higher infill densities and the pattern you choose also makes a difference.

I generally use cubic for its good all around support for multiple directions but for large flats I will either use a modifier mesh to increase the infill % immediately below the surface or combine that will a rectilinear or grid infill too to provide the needed extra support.

As for the lack of a sock, I'm not familiar with the socks for a mini but did it interfere with cooling airflow from the parts fan ? Air flow is a funny thing and even a mm difference around the size of parts can make a big difference.

RE:

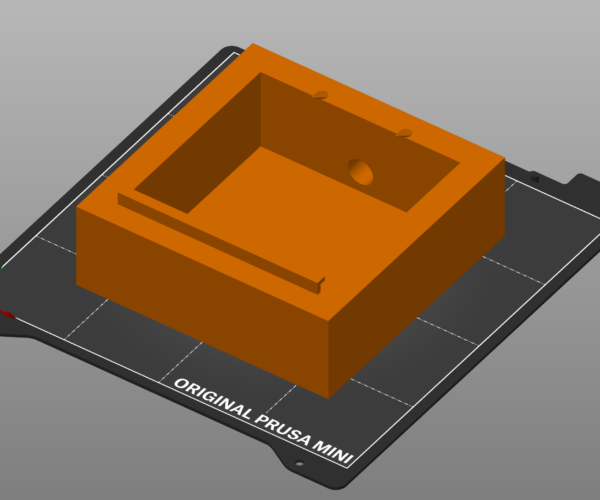

Yeah, I didn't have any problems with first layers or any side layers or other features. Before my original post, I printed an 8 hour print and everything about it was fine except the very top layer above the infill. Unfortunately I don't have pictures of that print handy, but this was the model:

Everything about this (first layer, sides, infill, supports, overhangs) was fine except the very top layer on all those walls. Those looked like my earlier test prints posted here with holes all the way down into the infill. The fact that so many things worked on that print makes me think there wasn't any change in extrusion or blocked nozzle or anything like that.

The airflow question is interesting. I did not notice when feeling by hand that this was causing any problems for airflow, and I did have many prints with this sock that were fine before the problem started. So the sock was not a new variable when the problem started but it was something taken away when it improved. I'm kinda at a loss to understand how that might be though. Maybe the sock was sagging a little in the back over time or something and I didn't notice? I'll think about it some more. Still I'm confused why I wouldn't also have started having problems with other things like general bridging if the cooling was the problem. The first layer on top of the infill has a lot of gaps to bridge, but they're all of uniform size... but is that somehow the most sensitive print feature to airflow?

I'll continue testing and hopefully I can find anything else wrong.

RE: Sudden top layer problems

Bridging is very sensitive to cooling, it’s why even for filaments that require less cooling it has its own fan speed settings so it can be boosted up. If it sags then the layer above has nothing to stick to so it sags too. Same with the next and so on. If you have enough top layers configured it can recover but you need many top layers and none of the usual profiles have anywhere enough. That’s why increased support is needed.

When the layers sag and don’t bond you can also get some strands that do receive cooling bowing upwards so you get all sorts of weird effects, wave like often in pattern.

Part cooling is one of the weakest areas of a Prusa printer I think. Mainly due to the fact the fans run on 5v unlike most printers that use 12v or higher and so usually move more air. Then again it’s possible to go the other extreme too lol. I had to turn the fan down on my modded cr10 as it pushes too much air and can cause problems with blowback cooling the extruder. It can do 150mm bridges though sometimes so I guess it balances out.

Anyway I hope you figure it out.

RE: Sudden top layer problems

I'd increase infill density, increase cooling on bridging (because the top most infill layer is bridging basically), and use 5 top layer at least.

RE: Sudden top layer problems

@Josh did you get this resolved?

I'm having the same issue.

Thanks

RE:

Have you calibrated your e-steps? I finally did it and came up with 349 instead of the stock 325. That made a big difference for my top surfaces.

See this thread for reference: Prusa Mini Extrusion E Steps Calibration Under Extrusion – Hardware, firmware and software help – Prusa3D Forum