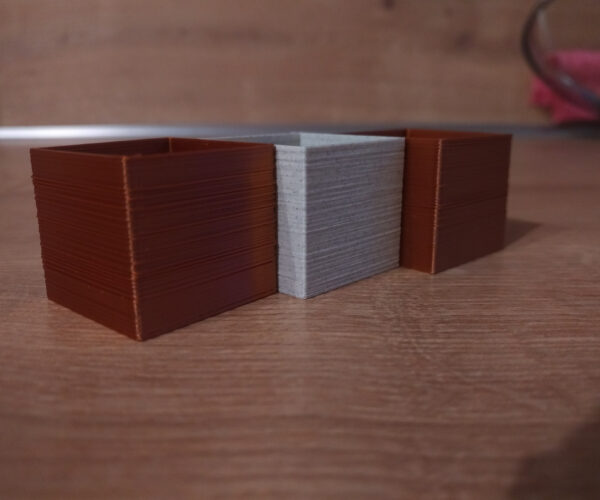

random protrusions in some layers

Hello Mates...

since two weeks my mini- made some really bad protrusions at some random layers

Meanwhile I tried many things (including texting the support) but I think they cant help me ether...

I think may my "nut" on Z-axis is a bit loose. (what do you think?)

Here the tings I tried:

- changed some slicing settings (also with gcode from prusa-support)

- tried very fresh filament

- adjusted the flowfactor (till its much to low)

- chacked all the belts (with prusa tension tester)

- cleaned Z-axis and all bearings (also in extruder) (added some lube (original prusa))

- installed the bondtec headbreak and NozzleX-Stained Steel nozzle

- adjusted the x-axis (as best as I could) so the Z-axis don't need to move that much

- installed the new firmware on the mini-

after each change I tried to print again. No step helped.

I printed an external sliced acceleration test. (2 different accelerations) and the faster one does not have these protrusions.

does anyone of you has a good idea what to do next?

(may its a driver oder the motor?)

many thanks!

edit:

sometimes there are good print in between.

and here comes the video:

https://drive.google.com/file/d/199slRhrF9LdBf_Nj3R4vj39GZtke1tKc/view?usp=sharing

Greetings from Germany!J.P.

Z Banding

It is subtle but I think that is Z Banding:

https://all3dp.com/2/3d-printer-z-banding/

--------------------

Chuck H

3D Printer Review Blog

Interesting

Wow, thank you

RE: random protrusions in some layers

I got my problem!

I changed the heatbreak to the Bondtec heatbreak. But I think the instructions ware wrong. I took the instructions from prusa and it worked. The problem was, there was a tiny gap between the heatbreak and the nozzle on the inside of the heatblock.

In my opinion it´s the best to fully tighten the heatbreak and than screw the nozzel. If there is a little gap between the nozzle and the heatblock, may unturn the heatbreak half a turn and try again.

This was the solution of my problem.

Greetings from Germany!J.P.