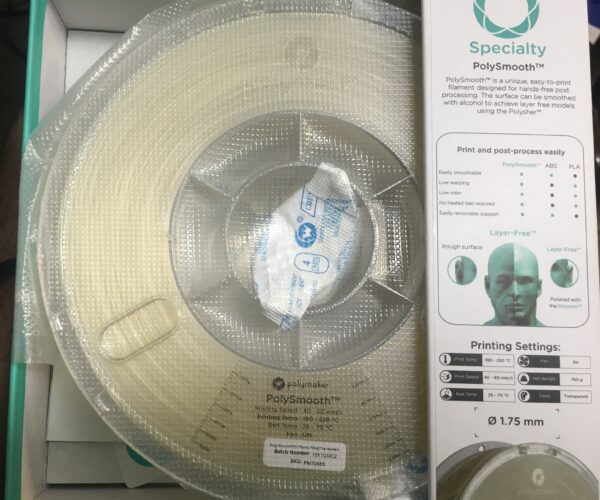

PVB - Polyvinyl butyral (PolySmooth by Polymaker etc)

Hi

I am looking for some information before purchasing a Prusa Mini.

I have searched the forum but can not find any information regarding the filament named PVB.

It looks very interesting to me for the usecase of printing detailed models and do some post processing to smoothen the surface using isopropyl alcohol.

I wonder:

- Is there another name for PVB, used by the community and that is the reason I can not find any information?

- Are there any information how it performs on a Prusa Mini? (I already know it uses similar temperatures as PLA)

- Do I need a certain nozzle?

- Most importantly, why can I not find it in the shop at https://shop.prusa3d.com? I would like to buy it.

Appreciate any information.

(This is my first post and I hope I do not violate any rules)

RE: PVB - Polyvinyl butyral (PolySmooth by Polymaker etc)

I don't think Prusa stock PVB.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PVB - Polyvinyl butyral (PolySmooth by Polymaker etc)

I think PVB is a specialty fr0m Polymaker (thats their PolySmooth), I havent seen any other companies manufacturing this type of filament :/

RE: PVB - Polyvinyl butyral (PolySmooth by Polymaker etc)

PoyMaker is the only seller I've seen. Interesting stuff if you want to do smoothing. Otherwise, it's just so-so as a PLA substitute, at least in my limited testing.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PVB - Polyvinyl butyral (PolySmooth by Polymaker etc)

I also have used it and still have most of a roll of clear. it's fun to play with and prints just fine, but isn't really practical for it's intended use, also you had to use a vaporizer (an IPA vaporizer) to get the advertised results in terms of smoothing quality. At last check the machine was roughly In the $300 US range, you can smooth without it but its not that great (this is just my opinion). but all the information is on the box for you.

Enjoy

The Filament Whisperer

RE: PVB - Polyvinyl butyral (PolySmooth by Polymaker etc)

I noticed that Prusa has introduced quite a few PVB filaments, all which appear to be in stock, and at a reasonable price.

Has anyone who has used PVB had any success getting better apparent transparency with it than with so-called transparent ABS or PETg?

The accompanying blog item (below) says it's not that great for mechanical parts, but I'm thinking in terms of window panes for model buildings and model railroad cars and such.

I don't think that the smoothing aspect would be a go/no-go item, except maybe if it helped with the apparent transparency.

RE: PVB - Polyvinyl butyral (PolySmooth by Polymaker etc)

This is an old thread but I thought I should add to it my experience. I recently printed a bunch of vases plus some other stuff (such as the inside of a Stargate). PVB printed fine on both Mk3S and Mini. I didn't spend the $300 for a vaporizer and simply applied IPA with a brush, 5 or 6 times, with drying in between. This stuff is just awesome! With the PLA treatment it really looks like glass, especially if printed with a 0.8mm nozzle and vase mode.

The only caveat is that the object gets really soft during the IPA treatment so careful handling is required (as you can see on the impressions I left on the top rim of this vase :-().

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: PVB - Polyvinyl butyral (PolySmooth by Polymaker etc)

I take it then that almost any of the common solvents, including the alcohols, will ruin prints.

RE: PVB - Polyvinyl butyral (PolySmooth by Polymaker etc)

don't try to do shots of tequila out of it.

Cheers

Swiss_Cheese

The Filament Whisperer

RE: PVB - Polyvinyl butyral (PolySmooth by Polymaker etc)

I'm more into single malt whisky!

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: PVB - Polyvinyl butyral (PolySmooth by Polymaker etc)

you and I would get along just fine 🍻

The Filament Whisperer

RE: PVB - Polyvinyl butyral (PolySmooth by Polymaker etc)

I don't do shots, unless someone buys a round of them and I'll pretend to enjoy it. More like beer and mixed drinks for me.

Anyway, I've had real good luck doing some jewelry pieces with Hatchbox clear ABS and smoothing with acetone. Photos in some other threads here.

This stuff sounds like it would be attacked by about anything, like even household cleaners or perfumes or insect spray. I've never used it but I would be afraid it would be too easily damaged.

RE: PVB - Polyvinyl butyral (PolySmooth by Polymaker etc)

I'm having some problems printing polymaker PVB on my mk3s+ using 0.6 nozzle

It will print fine until a certain point and then start accumulating excess material on a corner, then the extruder will crash into it and the print will fail.

It has started to happen with some PETG prints as well

Did not happen before the last firmware update, but maybe there's another reason? mechanical? slicer setting?

Cheers