printing fail - filament feeding issue?

Just got the pritner for 3 days, have tried a few succesful print for a few time,

but suddenly found the print started to have problem, when it come to a second layer,

it always seems lack of material coming out, and it cannot complete a full path for each layer when,

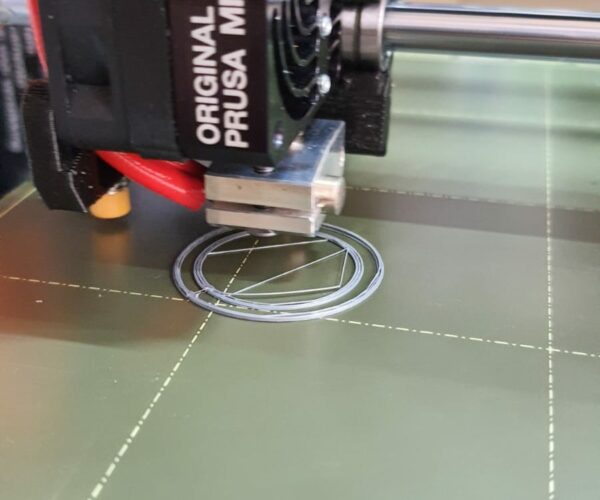

below show i m printing a cylinder, but the PLA didn't stick to the layer on below layer and starting to flow on the air....

I just use prusa PLA, and didn't change any setting from previous successful printing.....

Did anyone have a same or similar problem?? Or how can i fix it??

RE: printing fail - filament feeding issue?

Yes I just had that problem also, it was my extruder the screw in the back right below where the filament goes in the extrude needed to be adjusted.

1. Unload filament

2. Took off Bowden tube and feeding from front of extruder, Be careful there’s a small Bowden tube in side.

3. Look down in front you should be able to see all the way through make sure nothing is stuck in there clogging it up.

4. Take the adjustment screw completely out, this will release the front door also check to make sure nothing stuck or clogged.

5. Do the same for the top door if everything is Clear.

6. Put your Filament all the way through making sure you have a clear path leave it sticking out the front end.

7. Reinstall adjustment tightened down until you feel it snug around the filament not too tight then with your thumb move the gear on top back-and-forth to make sure the filament moves easy and clean through. just, tightened down until you feel it snug around the filament not too tight then with your thumb move the gear on top back-and-forth to make sure the filament moves easy and clean through. Remember the screw and spring hold the front door in place.

8. Then I pretended like everything was hooked up and went through loaded procedure, with my filament and with the front Bowden tube still off .

9. Inspect the filament make sure it’s not being crushed or chewed and was going through the extruder, then I unloaded it to make sure that worked I did it a couple times, to tweak it if I had to.

9. I have to complaining that I back out the filament leave about a inch Sticking out the front of the extruder.

10. Then I took small Bowden tube slid it down the filament into the extruder make sure it was lined up. Then I did the same with the brass fitting making sure it’s not too tight so I would not damage the small bone tube inside.

11. Then I reinstalled the Bowden tube that goes to the nozzle.

12. Then loaded my filament like usual making sure it was coming out the end of the nozzle.

13. Then I did two different test print make sure it was working properly.

14. The clicking also stopped stop and the filament didn’t have any issues so far.

I know this is a lot to do but it’s only way to ensure you got a clear path to the extruder and it’s adjusted correctly.

Let me know if this works for you, the only other thing it could be is the height from board to nozzle but it’s pretty simple to fix. Hope this works for you

Richard

RE: printing fail - filament feeding issue?

Just followed your steps and now its seems getting well!!! So much thanks for your details solution!!

I also just tuned up the nozzle height as I found that was quite a common problem from many other MINI user.

What an amazing help~ Thanks Richard!!

Ken

RE: printing fail - filament feeding issue?

Glad I could help!

Richard

RE: printing fail - filament feeding issue?

Hi, I’m having the very same issue but this time with an i3 Mk3s.

Any chance you or someone can offer similar steps to correct the same problem on this printer (please)

RE: printing fail - filament feeding issue?

I had my first failed print today on my mini on flexible filament(40D/85A). After I cleared the jam in the extruder I tried to preheat for PLA and the hot end set point was set to 215 but the hot end temp will not go above 170. I tried multiple preheat options and regardless of the set point the hot end temp stops at 170 exactly.

Just wondering if anyone has seen this? I have had the printer for a month with lots of successful prints but...

Firmware Version 4.1.0

RE: printing fail - filament feeding issue?

I had the exact same problem. Many other fixes did not work. I just replaced the plastic tube that is in the extruder.

I tried multiple things, and nothing worked. I was able to still print ABS and that was fine. PLA still didn't work.

I found the below YouTube video. I would have tried it, but it seemed laborious and I didn't have a 1.5 mm wrench

And then seeing the equally difficult fix in another post on this thread,

I just replaced the plastic tube inside the extruder.

I noticed there was a small ring of filament in the bottom of the extruder just above the nozzle. It kept fishing it out with filament. I would force filament through the extruder when it was heated to try and clean it out. As I pulled the filament out, it brought up that small ring.

The old tube was about 1.5 mm shorter than a replacement tube (the replacement tube came with the Prusa mini). Instead of going through the extruder, filament was coming up and filling the space under the tube. This would cool and cause clogs.

So, just replace the extruder tube with the replacement tube that came with the Prusa mini. Unscrew the brass double-ended bolt, pull out the tube, and replace. Be sure to force some filament down it when the nozzle is at 'load filament' temperatures, and fish out the filament ring if there is one.