PETG Melts/Ripp Off in the Extruder

Hi,

I have a pre-Assembled Mini+ und printed 2 Rolls Prusament PLA without any Problem. Now I was trying Prusament PETG. The First Print was really Good. Two other Prints was made in Vase Mode, also Good. Then the Bad Luck happens. I tried to print Easer Bunnys. I printed 8 other with PLA before, no Problems. Opened an new Vacumed Prusament PETG Box an start Printing.

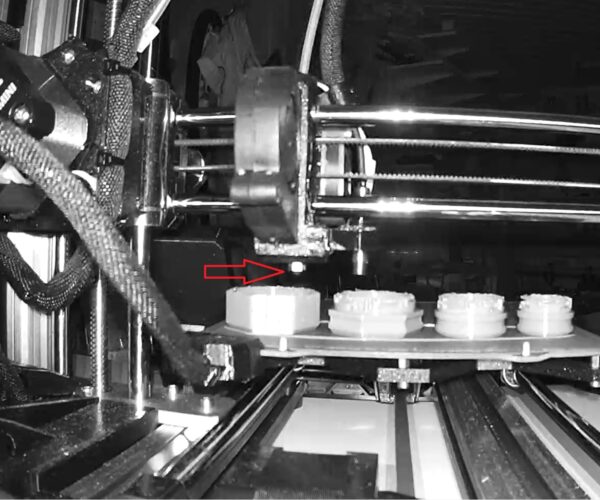

After 20%-25% of the Printing Time (1h of 4h) the Nozzle is doing there Job but there is no Filament coming out. Its not clogged, the Filament is ripped in Half in the Extruder, i cant transported forwards or Backwards.

I Unscrew and open the Extruder, pull the Filament out, cleaning the Gear assemble them and insert new Filament.

Works in the next Print...BUT after more or less same time. It happens again. The Print took the whole time but after 25% there is no Filament coming out because the Extruder can't push it forwards. The Nozzle is Printing in the Air but with no Filament.

Same Play, clean Extruder....

Loaded another PETG Prusament Filament and...Same Problem but this time in another Color 🤔 It also happened with another stl.

I happened in 4 of 5 Prints with 2 differents Spools. Only one Bunny was printed "ok" but with massive Stringing.

Now I am drying the PETG in a Spool Holder Heating Box for 20h , but I dont think it will make a different, one Spool was new and the Other 2 Days old.

After that i Inserted PLA and two Prints came out really good, like every print before.

What is the problem with the PETG Prusament or is it Bad Luck?

Prusa Mini+ stands in the Basement with 20° C. Prusament PETG Profil used in the Prusa Slicer, nothing else Changed.

RE: PETG Melts/Ripp Off in the Extruder

My opinion: you hotend is clogged.

Extruder is trying to push the right amount of filament, but is unable to do that (clog or other obstruction in filament path).. and so extruder starts grinding the filament.

You say it prints ok (which I doubt) until extruder starts grinding filament. That's because you probably have quite high tensinon on extruder. If tension would be right, then you'd hear extruder "clicking".

So, what to do? Take hotend apart and check how it looks inside.. don't forget to check the length of PTFE tube!

[Mini+] [MK3S+BEAR]

RE: PETG Melts/Ripp Off in the Extruder

I had exactly the same issue today thrice already. Did you follow Bogdan‘s hint and solve it that way? Or somehow else?

RE: PETG Melts/Ripp Off in the Extruder

So what I did was two cold pulls and there were no signs of other filaments in the hotend. If you shine a light through the empty hotend it is also totally clean, so I would also suppose a clogged hotend is not the answer (or I as a newbie got that totally wrong?).

RE: PETG Melts/Ripp Off in the Extruder

I don't know if the issue is solved.

What you can check is that the filament is smoothly feeding into the extruder. This interface is critical and often overlooked. The use of dry boxes with long and possible bended teflon tubes could increase the friction. This add to the normal bowden pressure into the nozzle. An other extruder with more power (and better grip to the filament) solve the issue, but not the initial problem with the filament feeding. So optimized free filament feeding is the way to go.

My 50 cents ...

RE: PETG Melts/Ripp Off in the Extruder

I have some cautios optimism the reason for me is humidity. I don't know about the "heated drybox" of @stread, but after drying my filament for 6 hours in the oven at 70°C my problematic filament roll prints great without further issues.