Mini+ Extruder Clicking Without Underextrusion

Hello,

I have had my Prusa Mini+ for just over a year and I love my little printer, sitting right next to me on my desk. But now the printer will not stop clicking, the extruder has been clicking for a month now and I hate it.(It doesn't help that I have like a PTSD to the clicking after I had hotend PTFE issues when I first got the printer) It all really started after I put on a new nozzle(this was the first time I had put on a nozzle and I still had the stock nozzle on) I followed the Prusa guide and did everything as specified and then made sure to hot tighten. After that all it does is click like nuts. The nozzle is put on correctly, I know that. And I know that the printer does not click with PETG, just PLA(I haven't tried others) The clicking seems to have a small effect on the print quality but nothing major(stringing, sloppy small details, etc.). I have been using Overture PLA and I'm almost through the spool(literally less than 70m) and it printed fine up till this point. I am hopefully going to get some more PLA so I can have enough to get it running again. I know that a well taken care of printer is not supposed to have a clicking extruder so I have looked at many fixes to my problem but all to know avail. So far I have:

- Contacted Prusa Support

- Double, triple, quadruple, etc. checked the idler tension

- Lots of cold pulls

- Reseated the hotend PTFE(I know it can shrink over time)

- Tried changing print temperatures to minimize heat creep(I use mostly PLA)

- Reattached and tune in the mesh between the spur gear and the stepper in the extruder(this thread)

- Double checked nozzle attachment to the heatblock to make sure I did it properly(it was)

I would appreciate any thought on what to do to fix this because Prusa support didn't quite understand my trouble.

Thank You

Best Answer by BogdanH:

First I need to say is, it's impossible for me to know what exactly the cause of your problem is. I'm just following my logic from experience and information that I've gathered on internet.

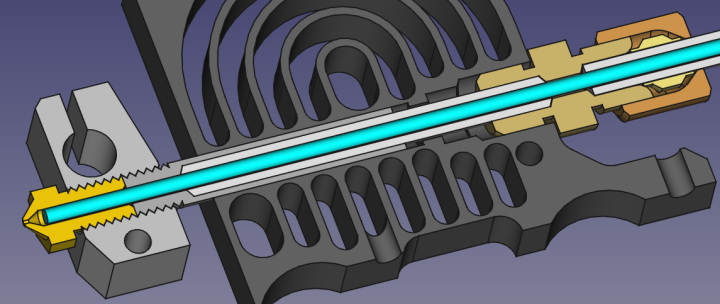

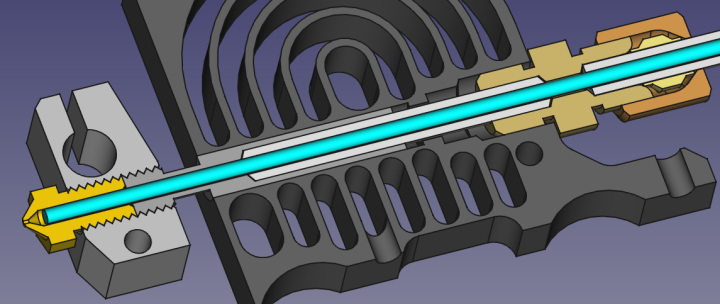

Ok, to answer the question why is there only trouble with PLA, while PETG is printing fine. PETG requires much higher temperature than PLA. PTFE tube can withstand up to about 260°C, so that's not the problem. Problem is, over the time, it will shrink at about 190°C. Normally, heatbreak should prevent such high temperatures to occur in PTFE area (that's why it's called heat-break). But reality is, the design of stock heatbreak is quite poor in this regard:

-ss soon PTFE tube (white on above image) shrink just a little, there will be very small gap at the bottom where chamfer is. While printing, this gap is filled by PETG (again, it's very small gap). When you go back to PLA, temperature is much lower and so remains of PETG will not soften enough. And these remains are now obstacle for filament.

The length of PTFE tube (tip to tip) should be 43,5mm. If you're not sure about measuring, keep in mind: it is ok if tube is 0,5mm longer, but it should not be shorter!

You can buy (1,75mm diameter) PTFE tube at many 3D print shops.. if you're in Europe, try here -it's not the cheapest, but it's quick delivery. There are several chamfer tools available for download (I'm using this).

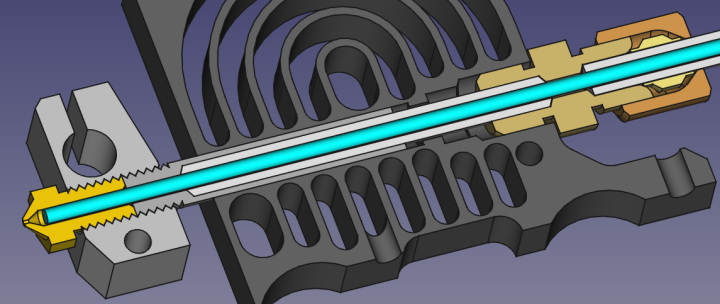

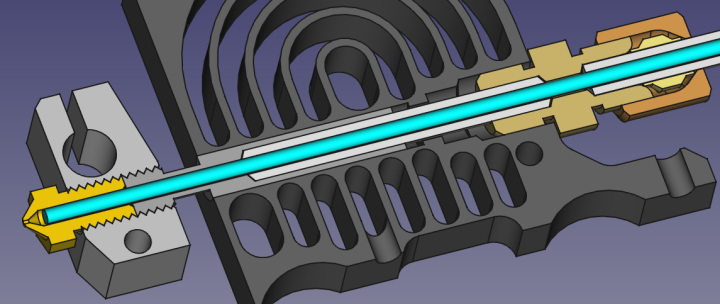

Yes, I use Bondtech heatbreak since day one and have no problems whatsoever. If you compare previous image with this one, you will understand:

-as you can see, with Bondtech heatbreak, it's impossible for PETG to be exposed to high temperature.

I also have Bondtech dual extruder, which I can recommend as well -it runs very smooth and makes tension adjustment much easier. Actually, in my opinion, heatbreak & extruder are the only upgrades for Mini to become reliably machine.

Ok, Bondtech extruder is kinda expensive... but then, you only buy once. If you think about cheaper alternative, then you should look after TriangleLab extruder & heatbreak (on AliExpress). I think TriangleLab is direct clone of Bondtech and seems to be of high quality. However, some patience for shipment is required.

Btw. For Bondtech (TriangleLab) heatbreak, the length of PTFE tube is 36mm.

RE: Mini+ Extruder Clicking Without Underextrusion

First we need to answer the question: what makes extruder clicking? There can only be two reasons:

1. There's something wrong with extruder itself: something lose or misplaced, wrong tension, some part inside wore out (grinding), wrong E-step setting, etc.

2. Something on filament path is preventing extruder to push correct amount of filament: remains of filament in PTFE tube between extruder and print head, partial clog in hotend.

You say there's no under-extrusion... How do you know that? Did you make extruder calibration? I ask, because if extruder is clicking, that automatically causes under-extrusion.

Many user usually increase tension when they start hearing clicking, which sometimes helps, but only temporary. The correct way to solve this, is to find the real reason.. by inspecting the extruder and/or to find the obstacle in filament path.

[Mini+] [MK3S+BEAR]

RE: Mini+ Extruder Clicking Without Underextrusion

So I don't entirely know what is making the extruder clicking.

There are no filament shaving in the spur so I don' t believe there to be a blockage. I have disassembled the extruder multiple times and everything, including the spur gear and stepper mesh, seems appropriately tight. The idler screw is tensioned well, I have played with it and got it to what seem correct. I am using the same E-steps that came with my printer when I purchased it.

I don't believe that there are any obstructions in the filament path. The bowden tube looks clear and I have, like I already said, gone through and clean out the hotend from any debris(there was a little but is looks clear now). I plan to go through, as soon as I have some parts, and double check the heatbreak for debris.

When I say there is no underextrusion I mean that I can still get through a print without too many quality issues, except those from my old PLA(I don't think this is the problem because I had some old Prusament PLA a couple months ago that printed fine). I honestly don't understand why the printer can still print fine(at least what I consider fine) but continue to drive me crazy.

As I said this all started when I changed my nozzle from the stock E3D nozzle that came with the printer(which was long overdue to be changed) to another that came in a pack of cheaper knockoff that I got off of Amazon. I think I have it all installed right since I follow the instructions from Prusa but maybe not.

One note: I have printed a temp tower for this PLA and the clicking was almost gone when running the hotend at 195C. However I have tried to print at that temperature since and overall nothing changes. I have also run the hotend to a higher temperature but that only leave the filament to come out slightly burnt.

RE: Mini+ Extruder Clicking Without Underextrusion

I'm sure you probably installed nozzle correctly.. if not, melted filament would came out at nozzle thread or at the top of the heater block. Usually cheapo 3rd party nozzles are of quite poor quality (finish inside the nozzle), but they're still usable.

In most cases, troubles (like yours) start when you start printing with PETG, and then go back to PLA. I won't go into details, because it was discussed here many times. In short: there must be partial clog inside heatbreak (because PTFE tube inside heatbreak shortened). Cold pulls are crap (ok, they are temporary solution sometimes). Take hotend apart, check it, clean it, replace PTFE tube and that's it. If you already disconnected PTFE tube between extruder and printhead in past, check the brass olive. If PTFE tube screw on top of print head is tightened too much, that will damage the olive permanently. That is, olive will shrink, and so internal diameter of PTFE tube shrinks as well -an obstacle in filament path.

If you plan to print PETG in future (of course you do), then I can highly recommend replacing stock heatbreak with Bondtech heatbreak. It's a 15€ solution worth every cent. And being at that, get original nozzle -just to be sure everything is correct.

[Mini+] [MK3S+BEAR]

RE: Mini+ Extruder Clicking Without Underextrusion

I have all ready reseated the hotend PTFE. I admit I didn't use a new piece of PTFE(I don't have one or know where to get one that is cheap with the nice chamfer in it) but my old one has no imperfections that I can see. I will go through and do it again as soon as I get some new bolts in replacement for the grub screws(see here). I still don't think there is a partial clog because filament continues to from the nozzle fairly consistently(except that for which we all see occasionally).

I don't print PETG regularly but I have gone through at least 1kg of it. Actually my printer doesn't click when I print with PETG(I tried it recently it all seems fine with PETG).

Have you tried the Bondtech heatbreak? I have been looking at it lately. Is it possible that I am having some heat creep issues with PLA because of it low thermal resistance but not with PETG because it remains less pliable in the heatsink. If you have tried the Bondtech heatbreak do you think that it would fix the heat creep? Also if I get the heatbreak should I get the dual drive extruder to compliment it?

Also one question about nozzles. Should I, after get my printer running well again, get a plain brass nozzle or one of its counterparts?(3D Solex, E3D Stainless Steel, NozzleX, Copper Plated, etc....)

RE: Mini+ Extruder Clicking Without Underextrusion

First I need to say is, it's impossible for me to know what exactly the cause of your problem is. I'm just following my logic from experience and information that I've gathered on internet.

Ok, to answer the question why is there only trouble with PLA, while PETG is printing fine. PETG requires much higher temperature than PLA. PTFE tube can withstand up to about 260°C, so that's not the problem. Problem is, over the time, it will shrink at about 190°C. Normally, heatbreak should prevent such high temperatures to occur in PTFE area (that's why it's called heat-break). But reality is, the design of stock heatbreak is quite poor in this regard:

-ss soon PTFE tube (white on above image) shrink just a little, there will be very small gap at the bottom where chamfer is. While printing, this gap is filled by PETG (again, it's very small gap). When you go back to PLA, temperature is much lower and so remains of PETG will not soften enough. And these remains are now obstacle for filament.

The length of PTFE tube (tip to tip) should be 43,5mm. If you're not sure about measuring, keep in mind: it is ok if tube is 0,5mm longer, but it should not be shorter!

You can buy (1,75mm diameter) PTFE tube at many 3D print shops.. if you're in Europe, try here -it's not the cheapest, but it's quick delivery. There are several chamfer tools available for download (I'm using this).

Yes, I use Bondtech heatbreak since day one and have no problems whatsoever. If you compare previous image with this one, you will understand:

-as you can see, with Bondtech heatbreak, it's impossible for PETG to be exposed to high temperature.

I also have Bondtech dual extruder, which I can recommend as well -it runs very smooth and makes tension adjustment much easier. Actually, in my opinion, heatbreak & extruder are the only upgrades for Mini to become reliably machine.

Ok, Bondtech extruder is kinda expensive... but then, you only buy once. If you think about cheaper alternative, then you should look after TriangleLab extruder & heatbreak (on AliExpress). I think TriangleLab is direct clone of Bondtech and seems to be of high quality. However, some patience for shipment is required.

Btw. For Bondtech (TriangleLab) heatbreak, the length of PTFE tube is 36mm.

[Mini+] [MK3S+BEAR]

RE: Mini+ Extruder Clicking Without Underextrusion

Forgot about nozzle... Just get original E3D standard brass nozzle. In that case, if something doesn't work as expected, you will at least know you have the right thing.

[Mini+] [MK3S+BEAR]

RE: Mini+ Extruder Clicking Without Underextrusion

Thank you for the thorough explanations on the heatbreak and nozzles, I understand much better now what is most likely wrong. I am very glad to hear all this because Prusa support thought I needed to replace my entire hotend! I think I'll probably get the genuine Bondtech heatbreak but I will most likely just get the Trianglelab clone extruder. It seems like a pretty nice setup, I just wish I could find the files to print the assembly and just buy the hardware.

Regarding the PTFE tube I would like to ask, since I am in the United States, if you have any suggestions closer or online(Amazon, Matterhackers) that would be great. Also should I pay the extra money for something like Capricorn XS and while I'm at it upgrade the whole bowden tube as well?

RE: Mini+ Extruder Clicking Without Underextrusion

If you decide for dual drive extruder, I recommend to buy it complete. Because at this point, it's hard to say if you could print the housing with high enough precision. I suggested TriangleLab because some members of this forum gave positive feedback about it. However, you can also decide for the same extruder made by Fysetc, which is even cheaper. It must be said, that original Bondtech is of higher quality than both of these, but that probably isn't noticed in everyday use.

Anyway, when speaking about heatbreak, I think TriangleLab is the only cheaper alternative (and reliable at that). It can happen you find "similar design" on Amazon, but it will probably cost you the same as original Bondtech. Still, if you decide for it, make sure there's specified how long PTFE tube you need for it (Bondtech and TriangleLab use the same length).

Finding 1,75mm PTFE tube on Amazon shouldn't be a problem, though. In case you decide for Bondtech/TriangleLab heatbreak, then there's no need to buy Capricorn! I bough Capricorn and is still lying in the drawer -I never needed it.

I think there's no need you change bowden tube at this point, unless you see a reason for that -and you can do that anytime later without much hassle.

[Mini+] [MK3S+BEAR]

RE: Mini+ Extruder Clicking Without Underextrusion

In case you decide for Bondtech/TriangleLab heatbreak, then there's no need to buy Capricorn! I bough Capricorn and is still lying in the drawer -I never needed it.

That is amazing, I can't believe that the Bondtech heatbreak keeps the heat separated that well.

Thank you @BogdanH for all the help! Hopefully with all of this information I can get my printer running reliably.

I will try to post some photos of my 'Upgraded Mini+' so anyone else will be able to understand this issue and fix it accordingly.

Once again, thanks!